Abstract

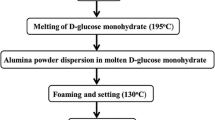

The presented paper reports on the results of preparation of alumina foam with ideal polyhedral shapes of bubbles-pores. The foam was prepared by direct foaming method using partially hydrophobized Al2O3 particles, where dodecylbenzenesulfonic acid was used as a hydrophobization agent. A polyhedral shape of the bubbles was achieved by “water procedure”, in which the alumina foam prepared by the direct foaming method was poured into twice its volume of water and mixed. After the mixing was stopped, the particles with an inadequate contact angle were washed out from the system of the alumina foam by draining. The foam was formed only from particles which were physically bound in the lamellas and the bubbles were arranged in ideal polyhedral shapes. The water procedure increases the foam stability, allowing for preparation of alumina foams with porosity of 99 %.

Similar content being viewed by others

References

T. Gonzenbach, A.R. Studart, E. Tervoort, L.J. Gauckler, J. Am. Ceram. Soc. 90, 16–22 (2007)

T.N. Hunter, R.J. Pugh, G.V. Franks, G.J. Jameson, Adv. Colloid Interface Sci. 137, 57–81 (2008)

G. Kaptay, Colloids Surf. A 282–283, 387–401 (2006)

M. Vignes-Adler, D. Weaire, Curr. Opin. Colloid Interface Sci. 13, 141–149 (2008)

A.R. Studart, U.T. Gonzenbach, E. Tervoort, L.J. Gauckler, J. Am. Ceram. Soc. 89, 1771–1789 (2006)

J. Luyten, S. Mullens, J. Cooymans, A.M. De Wilde, I. Thijs, R. Kemps, J. Eur. Ceram. Soc. 29, 829–832 (2009)

P. Colombo, Phil. Trans. R. Soc. Lond. Ser. A 364, 109–124 (2006)

E.D. Manev, A.V. Nguyen, Int. J. Miner. Process. 77, 1–45 (2005)

U.T. Gonzenbach, A.R. Studart, E. Tervoort, L.J. Gauckler, Langmuir 22, 10983–10988 (2006)

W. Ramsden, Proc. R. Soc. Lond. 72, 156–164 (1903)

S.T. Tobin, J.D. Barry, A.J. Meagher, B. Bulfin, C.E. O’Rathaille, S. Hutzler, Colloids Surf. A 282, 24–31 (2010)

D. Exerowa, P.M. Kruglyakov, Foam and foam films, studies, in Interface Science, vol. 5, ed. by D. Möbius, R. Miller (Elsevier, Amsterdam, 1998), pp. 14–25

Z. Holková, L. Pach, D. Lath, J. Krištín, Chem. Pap. 58, 149–154 (2004)

Z. Bazelová, L. Pach, J. Lokaj, V. Kovár, Ceram. Silik. 55, 241–246 (2011)

B.P. Binks, Curr. Opin. Colloid Interface Sci. 7, 21–41 (2002)

B.S. Murray, R. Ettelaie, Curr. Opin. Colloid Interface Sci. 9, 314–320 (2004)

T.N. Hunter, R.J. Pugh, G.V. Franks, G.J. Jameson, Adv. Colloid Interface Sci. 137, 57–81 (2008)

T.S. Horozov, Curr. Opin. Colloid Interface Sci. 13, 134–140 (2008)

G. Kaptay, Colloids Surf. A 230, 67–80 (2003)

P. Sepulveda, J.G.P. Binner, J. Eur. Ceram. Soc. 19, 2059–2066 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hajdúchová, Z., Pach, L., Kozánková, J. et al. Polyhedral alumina foam. J Porous Mater 20, 595–600 (2013). https://doi.org/10.1007/s10934-012-9632-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-012-9632-8