Abstract

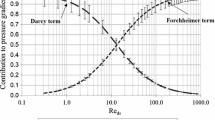

Many applications require fluid flow through the open pores of metal foam. The foam is usually treated as a porous medium for which the Darcy law and the Hazen-Dupuit-Darcy (or Forchheimer) equation are used to describe the pressure drop, and for obtaining the two important flow properties, i.e., the permeability and the form drag coefficient. Little or no attention is paid to the length (or thickness) of the porous medium in the flow direction. This paper establishes a minimum length necessary for the foam to have length-independent (or bulk) permeability and form drag coefficient. This minimum length is obtained experimentally for various types of open-cell aluminum foam subjected to airflow in the Forchheimer regime. Below this thickness values of the two key flow properties are not constant, and they include entrance/exit effects, which may explain some of the discrepancies in the reported values in the literature. The Forchheimer equation was recast in two different manners, which resulted in new non-dimensional numbers- one representing the form drag and the other the viscous drag. These numbers correlated very well with the thickness of the porous medium. The obtained correlations allow for determining the pressure drop given only the velocity and the thickness of an aluminum foam sample.

Similar content being viewed by others

Abbreviations

- C :

-

Form drag coefficient (m−1)

- C D :

-

Dimensionless form drag coefficient

- C V :

-

Dimensionless viscous drag coefficient

- F :

-

Universal drag coefficient (dimensionless)

- f :

-

Friction factor (dimensionless)

- f ND :

-

Viscous friction factor (dimensionless)

- K :

-

Permeability (m2)

- L :

-

Thickness of foam sample in the flow direction (m or cells)

- p :

-

Static pressure (Pa)

- p i :

-

Inlet pressure (Pa)

- p o :

-

Exit pressure (Pa)

- Re:

-

Reynolds number

- V :

-

Darcy velocity (m/s)

- δ:

-

Uncertainty (%)

- Δ:

-

Change

- ε:

-

Porosity (%)

- μ:

-

Kinematic viscosity of air (kg/m.s)

- ρ:

-

Density of air (kg/m3)

References

J. Zhou, W.O. Soboyejo, C. Mercer, Metall. Mater. Trans. 33A(5), 413–1427 (2002)

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal Foams, a Design Guide (Butterworth-Heinemann, Woburn, 2000)

W. Azzi, W.L. Roberts, A. Rabiei, Mater. Des. 28, 569–574 (2007)

J.J. Hwang, G.J. Hwang, R.H. Yeh, C.H. Chao, J. Heat Trans. 124, 120–129 (2002)

J.L. Lage, B.V. Antohe, D.A. Nield, J. Fluids Eng. 119, 700–706 (1997)

D. Seguin, A. Montillet, J. Comiti, Chem. Eng. Sci. 53(21), 3751–3761 (1998)

L. Tadrist, M. Miscevic, O. Rahli, F. Topin, Exp. Therm. Fluid Sci. 28, 193–199 (2004)

S.Y. Kim, J.W. Paek, B.H. Kang, J. Heat Trans. 122, 572–578 (2000)

J.W. Paek, B.H. Kang, S.Y. Kim, J.M. Hyun, Int. J. Thermophys. 21(2), 453–464 (2000)

J.S. Noh, K.B. Lee, C.G. Lee, Int. Commun. Heat Mass. Trans. 33, 434–444 (2006)

A. Bhattacharya, V.V. Calmidi, R.L. Mahajan, Int. J. Heat Mass. Trans. 45, 1017–1031 (2002)

J.P. du Plessis, A. Montillet, J. Comiti, J. Legrand, Chem. Eng. Sci. 49, 3545–3553 (1994)

J.G. Fourie, J.P. du Plessis, Chem. Eng. Sci. 57, 2781–2789 (2002)

J.F. Despois, A. Mortensen, Acta Mater. 53, 1381–1388 (2005)

K. Boomsma, D. Poulikakos, Y. Ventikos, Int. J. Heat Fluid Flow 24, 825–834 (2003)

K. Boomsma, D. Poulikakos, J. Fluids Eng. 124, 263–272 (2002)

B. Antohe, J.L. Lage, D.C. Price, R.M. Weber, J. Fluids Eng. 11, 404–412 (1997)

C. Naakteboren, P.S. Krueger, J.L. Lage, in Proceedings of the International Conference on Porous Media and Applications, Evora, Portugal, 24–27 May 2004

C. Naakteboren, P.S. Krueger, J.L. Lage, in Proceedings of the ASME Fluids Engineering Summer Meeting and Exhibit, Houston, TX, 19–20 June 2005

M. Medraj, E. Baril, V. Loya, L.P. Lefebvre, J. Mat. Sci. 42, 4372–4383 (2007)

M.D.M. Innocentini, L.P. Lefebvre, R. V. Meloni, E. Baril (2009) J. Porous Mat. doi: 10.1007/s10934-009-9312-5

E. Baril, A. Mostafid, L.P. Lefebvre, M. Medraj, Adv. Eng. Mat. 10(9), 889–894 (2008)

K.C. Leong, L.W. Jin, Int. J. Ht. Fld. Fl. 27, 144–153 (2006)

A. Bhattacharya, R.L. Mahajan, J. Elec. Pack 124, 155–163 (2002)

K. Boomsma, D. Poulikakos, F. Zwick, Mech. Mat. 35, 1161–1176 (2003)

J.F. Liu, W.T. Wu, W.C. Chiu, W.H. Hsieh, Exp. Therm. Fld. Sci. 30, 329–336 (2006)

O. Reutter, E. Smirnova, J. Sauerhering, S. Angel, T. Fend, R. Pitz-Paal, J. Fluids Eng. 130, 201–205 (2008)

J.P. Bonnet, F. Topin, L. Tadrist, Transp. Porous Media. 73, 233–254 (2008)

ISO 4638:1984—Polymeric materials, cellular flexible—Determination of air flow permeability

ISO 7231:1984—Polymeric materials, cellular flexible—Method of assessment of air flow value at constant pressure-drop

ASTM D737 Standard test method for air permeability of textile fabrics

ASTM F 778–88 Standard methods for gas flow resistance testing of filtration media

ASTM D3574-03 Standard test methods for flexible cellular Materials—slab, bonded, and molded urethane foams

J.P. du Plessis, S. Woudberg, Chem. Eng. Sci. 63, 2576 (2008)

J.L. Lage, B. Antohe, J. Fluids Eng. 122, 619–625 (2000)

S. Ergun, Chem. Eng. Progress 48(2), 89–94 (1952)

N. Dukhan, P. Patel, Exp. Therm. Fluid Sci. 32, 1059–1067 (2008)

ERG Materials and Aerospace, Oakland, CA. www.ergaerospace.com. Accessed March 2010

R. Figliola, D. Beasly, Theory and Design for Mechanical Measurements (Wiley, New York, 2000)

K. Vafai, C.L. Tien, Int. J. Heat Mass. Trans. 25(8), 1183–1190 (1982)

I.H. Shams, Mechanics of Fluids (Wiley, New York, 1992), p. 674

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dukhan, N., Patel, K. Effect of sample’s length on flow properties of open-cell metal foam and pressure-drop correlations. J Porous Mater 18, 655–665 (2011). https://doi.org/10.1007/s10934-010-9423-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9423-z