Abstract

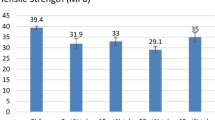

This research investigates the effect of talc additive on physical and mechanical characteristics of poly(lactic acid) (PLA) and poly(butylene succinate) (PBS) polymer blend. In the study, the talc content is varied between 0, 5, 10, and 20 parts per hundred resin (phr) and the PLA/PBS ratio is 80/20 w/w. The results reveal that talc enhances the mechanical properties of PLA/PBS blend. Specifically, tensile strength, Young’s modulus, and impact strength of PLA/PBS/talc composite increase as talc content rises. In addition, fracture toughness increases substantially as talc quantity is raised. The enhanced fracture toughness is attributable to nucleation of talc which promotes crystallization of PLA while hindering PBS crystal growth. Moreover, morphology analysis shows efficient distribution of talc in the polymer matrix.

Similar content being viewed by others

References

Kamm B, Gruber PR, Kamm M (2010) Biorefineries—industrial processes and products: status quo and future directions. Wiley, Hoboken, p 949

Nampoothiri KM, Nair NR, John RP (2010) An overview of the recent developments in polylactide research. J Biores Technol 101:8493

Tsuji H (2008) Polylactic Acid -Shokubutsu Yurai Plastic no Kiso to Ouyou. Yoneda Shuppan Co. Ltd, Tokyo

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. J Macromol Biosci 4:835

Auras RA, Singh SP, Singh JJ (2005) Evaluation of oriented poly(lactide) polymers with existing PET and oriented PS for fresh food service containers. J Packag Technol Sci 18:207

Vainionpaa S, Rokkanen P, Tormal P (1989) Surgical application of biodegradable polymers in humman tissues. J Prog Polym Sci 14:679

Pivsa-Art W, Fujii K, Nomura K, Aso Y, Ohara H, Yamane H (2016) The effect of poly(ethylene glycol) as plasticizer in blends of poly(lactic acid) and poly(butylene succinate). J Appl Polym Sci 133(8):43044

Jompang L, Thumsorn S, Wong On J, Surin P, Apawet C, Chaichalermwong T, Kaabbuathong N, O-Charoen N, Srisawat N (2013) Poly(lactic acid) and poly(butylene succinate) blend fibers prepared by melt spinning technique. Energy Proc 34:493

Jiang L, Wolcott MP, Zhang J (2006) Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromol 7(1):199

Bhari K, Mitomo H, Enjoji T, Yoshii F, Makuuchi K (1998) Radiation cross linked poly (butylene succinate) foam and its biodegradation. Polym Degrad Stab 62:551

Doi Y, Kasuya K, Abe H, Koyama N, Ishiwatara S, Takagi K, Yoshida Y (1996) Evaluation of biodegradabilities of biosynthetic and chemosynthetic polyesters in river water. J Polym Degrad Stab 51:281

Bhatia A, Gupta RK, Bhattacharya SN, Choi HJ (2007) Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. J Korea-Austr Rheol 19:125

Oksman K, Skrifvars M, Selin JF (2003) Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol 63:1317

Wang XH, Zhou JJ, Li L (2007) Multiple melting behavior of poly(butylene succinate). Eur Polym J 43:3163

Doi Y, Fukuda K (1994) Biodegradable plastics and polymer. Stud Polym Sci 12:627

Ujimaki T (1998) Processability and properties of aliphatic polyesters. Polym Degrad Stab 59:209

Shih YF, Chen LS, Jeng RJ (2008) Preparation and properties of biodegradable PBS/multi-walled carbon nanotube nanocomposites. Polymer 49:4602

Lapčík L, Jindrová P, Lapčíková B, Tamblyn R, Greenwood R, Rowson N (2008) Effect of the talc filler content on the mechanical properties of polypropylene composites. J Appl Polym Sci 110(5):2742

Stamhuis JE (1988) Mechanical-properties and morphology of polypropylene composites. 3. Short glass-fiber reinforced elastomer modified polypropylene. Polym Compos 9(4):280

Battegazzore D, Bocchini S, Frache A (2011) Crystallization kinetics of poly(lactic acid)-talc composites. Polym Lett 1(5):849

Shibata M, Inoue Y, Miyoshi M (2006) Mechanical properties, morphology, and crystallization behavior of blends of poly(l-lactide) with poly(butylene succinate-co-l-lactate) and poly(butylene succinate). Polymer 47:3557

Shakoor A, Thomas NL (2014) Talc as a nucleating agent and reinforcing filler in poly(lactic acid) composites. Polym Eng Sci 54(1):64

Battegazzore D, Bocchini S, Frache A (2011) Crystallization kinetics of poly(lactic acid)-talc composites. Exp Polym Lett 5(10):849

Huang A, Yu P, Jing X, Mi HY, Geng LH, Chen BY, Peng XF (2016) The effect of talc on the mechanical, crystallization and foaming properties of poly (lactic acid). J Macrom Sci Part B 55(9):908

Akbari A, Jawaid M, Hassan A, Balakrishnan H (2013) Epoxidized natural rubber toughened polylactic acid/talc composites: mechanical, thermal, and morphological properties. J Comp Mat 48(7):1

Pivsa-Art W, Fujii K, Nomura K, Aso Y, Ohara H, Yamane H (2016) Isothermal crystallization kinetics of talc-filled poly (lactic acid) and poly (butylene succinate) blends. J Polym Res 23(8):144

Picard E, Espuche E, Fulchiron R (2011) Effect of an organo-modified montmorillonite on PLA crystallization and gas barrier properties. Appl Clay Sci 53:58

Hassouna F, Raquez JM, Addiego F, Dubois P, Toniazzo Y, Ruch D (2011) New approach on the development of plasticized polylactide (PLA): grafting of poly (ethylene glycol) (PEG) via reactive extrusion. Eur Polym J 47:2134

Ren ZJ, Dong LS, Yang YM (2006) Dynamic mechanical and thermal properties of plasticized poly(lactic acid). J Appl Polym Sci 101:1583

Arruda LC, Magaton M, Bretas RES, Ueki MM (2015) Influence of chain extender on mechanical, thermal and morphological properties of blown films of PLA/PBAT blends. Polym Test 43:27

Asabia L, Jafari SH, Khonakdar HA, Hussler L, Wagenknecht U, Heinrich G (2013) Non-isothermal crystallization behavior of PLA/LLDPE/nanoclay hybrid: synergistic role of LLDPE and clay. Thermochim Acta 565:102

Hwang SY, Yoo ES, Im SS (2012) The synthesis of copolymers, blends and composites based on poly(butylene succinate). Polym J 44:1179

Ihn KJ, Yoo ES, Im SS (1995) Structure and morphology of poly(tetramethylene succinate) crystals. Macromol 28:2460

Piorkowska E, Kulinski Z, Galeski A, Masirek R (2006) Plasticization of semicrystalline poly(l-lactide) with poly(propylene glycol). Polymer 47:7178

García-Campo MJ, Boronat T, Quiles-Carrillo L, Balart R, Montanes N (2018) Manufacturing and characterization of toughened poly(lactic acid) (PLA) formulations by ternary blends with biopolyesters. Polymer 10:3

Yao SS, Pang QQ, Song R, Jin FL, Park SJ (2016) Fracture toughness improvement of poly(lactic acid) with silicon carbide whiskers. Macromol Res 24(11):961

Jin FL, Pang QQ, Zhang TY, Park SJ (2015) Synergistic reinforcing of poly(lactic acid)-based systems by polybutylene succinate and nano-calcium carbonate. J Ind Eng Chem 32:77

Acknowledgements

The authors would like to express sincere gratitude to the National Research Council of Thailand (NRCT) for research grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pivsa-Art, W., Pivsa-Art, S. Effect of Talc on Mechanical Characteristics and Fracture Toughness of Poly(lactic acid)/Poly(butylene succinate) Blend. J Polym Environ 27, 1821–1827 (2019). https://doi.org/10.1007/s10924-019-01478-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01478-z