Abstract

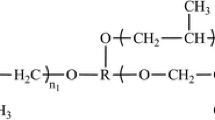

This study is focused on the fabrication and evaluation of polyurethane (PU) foam fabricated using soy-based polyol that can potentially replace conventional petroleum-based PU foam for thermal applications. Rigid soy-based PU foam samples investigated in this study were produced by copolymerization of diisocyanate with soy-based polyol in presence of Xiameter X0193 surfactant, dibutyltin dilaurate (DBTL) as a catalyst, and water as a blowing agent. Different formulations with varying amounts of blowing agent and catalyst were investigated to optimize the mechanical and thermal properties of soy-based PU foam when compared to commercial petroleum-based foam as a control sample. The prepared samples were tested for density, compressive strength, thermal conductivity, tensile strength, dimensional stability, and thermal stability using the ASTM standards. The cellular structure of the fabricated foam samples was investigated using scanning electron microscopy. It was observed that an increase in density leads to a decrease in insulation. Overall, soy-based foams exhibited similar thermal conductivity as compared to petroleum-based foams.

Similar content being viewed by others

References

Cornille A, Dworakowska S, Bogdal D, Boutevin B, Caillol S (2015) A new way of creating cellular polyurethane materials: NIPU foams. Eur Polym J 66:129–138

Shen L, Haufe J, Patel MK (2009) Report of Utrecht University commissioned by European polysaccharide network of excellence and European bioplastics. Utrecht University, 2009

Janik H, Sienkiewicz M, Kucinska-Lipka J (2013) Handbook of thermoset plastics, 3rd edn. William Andrew, Norwich

Sonnenschein M, Koonce W (2011) Encyclopedia of polymer science and technology. Wiley, Hoboken

Septevani AA, Evans DAC, Chaleat C, Martin DJ, Annamalai PK (2015) A systematic study substituting polyether polyol with palm kernel oil based polyester polyol in rigid polyurethane foam. Ind Crops Prod 66:16–26

Rashmi B, Rusu D, Prashantha K, Lacrampe M, Krawczak P (2013) Development of water-blown bio-based thermoplastic polyurethane foams using bio-derived chain extender. J Appl Polym Sci 128:292–303

Ionescu M, Wan X, Bilic N, Petrovi Z (2012) Polyols and rigid polyurethane foams from cashew nut shell liquid. J Polym Environ 20:647–658

Narine SS, Kong X, Bouzidi L, Sporns P (2006) Physical properties of polyurethanes produced from polyols from seed oils: II. Foams. J Am Oil Chem Soc 84:65–72

Sharma C, Kumar S, Unni A, Aswal V, Rath S, Harikrishnan G (2014) Foam stability and polymer phase morphology of flexible polyurethane foams synthesized from castor oil. J Appl Polym Sci 131(17):1–8

Palanisamy A, Rao B, Mehazabeen S (2011) Diethanolamides of castor oil as polyols for the development of water-blown polyurethane foam. J Polym Environ 19:698–705

Ugarte L, Saralegib A, Fernández R, Martín L, Corcuera M, Eceiza A (2014) Flexible polyurethane foams based on 100% renewably sourced polyols. Ind Crops Prod 62:545–551

Gama N, Soares B, Freire C, Silva R, Neto C, Barros-Timmons A, Ferreira A (2015) Bio-based polyurethane foams toward applications beyond thermal insulation. Mater Des 76:77–85

Tan S, Abraham T, Ference D, Macosko C (2011) Rigid polyurethane foams from a soybean oil-based polyol. Polymer 52:2840–2846

Pawlik H, Prociak A (2011) Influence of palm oil-based polyol on the properties of flexible polyurethane foams. J Polym Environ 20:438–445

Badri K, Ahmad S, Zakaria S (2001) Production of a high-functionality RBD palm kernel oil-based polyester polyol. J Appl Polym Sci 81:384–389

Tu Y, Kiatsimkul P, Suppes G, Hsieh F (2007) Physical properties of water-blown rigid polyurethane foams from vegetable oil-based polyols. J Appl Polym Sci 105:453–459

Gu R, Konar S, Sain M (2012) Preparation and characterization of sustainable polyurethane foams from soybean oils. J Am Oil Chem Soc 89:2103–2111

Zhang S, Xiang A, Tian H, Rajulu AV (2018) Water-blown castor oil-based polyurethane foams with soy protein as a reactive reinforcing filler. J Polym Environ 26(1):15–22

Hejna A, Kirpluks M, Kosmela P, Cabulis U, Haponiuk J, Piszczyk L (2017) The influence of crude glycerol and castor oil-based polyol on the structure and performance of rigid polyurethane-polyisocyanurate foams. Ind Crops Prod 95:113–125

Operating Service Manual, Quickline-30 Thermal Property Analyzer, Anter Corporation, March 2009

Ravey M, Pearce EM (1997) Flexible polyurethane foam: thermal decomposition of a polyether-based, water-blown commercial type of flexible polyurethane foam. J Appl Polym Sci 63:47–74

Allan D, Daly J, Liggat JJ (2013) Thermal volatilization analysis of TDI-based flexible polyurethane foam. Polym Degrad Stab 98:535–541

Dhaliwal GS, Anandan S, Chandrashekhara K, Lees J, Nam P (2018) Development and characterization of polyurethane foams with substitution of polyether polyol with soy-based polyol. Eur Polym J 107:105–117

Guo A, Javni I, Petrovic Z (2000) Rigid polyurethane foams based on soybean oil. J Appl Polym Sci 77:467–473

Kabir ME, Saha MC, Jeelani S (2006) Tensile and fracture behavior of polymer foams. Mater Sci Eng A 429:225–235

Acknowledgement

This work is supported by the Missouri Soybean Merchandising Council (Jefferson City, MO). The authors would like to thank Mr. John Miller (MCPU Polymer Engineering LLC. Pittsburg, KS) for providing soy-based polyol and Dr. Steven Harasin (Covestro LLC. Pittsburgh, PA) for providing isocyanate and Baydur 683 foam. Authors would also like to thank Mr. Stephan Johannesmeyer (Thermocore of Missouri, Jefferson City, MO) for his helpful suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dhaliwal, G.S., Anandan, S., Chandrashekhara, K. et al. Fabrication and Testing of Soy-Based Polyurethane Foam for Insulation and Structural Applications. J Polym Environ 27, 1897–1907 (2019). https://doi.org/10.1007/s10924-019-01477-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01477-0