Abstract

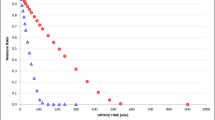

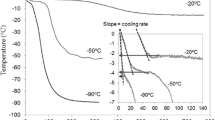

Mechanically deboned chicken meat protein concentrate (CMPC) was mixed with 30, 40 and 50% glycerol to produce films and physical, thermal, chemical, morphological and microstructural properties of films were characterized. The apparent porosity of films increased with increasing glycerol content which was due to the increase of free volume in film matrix (P < 0.05). The higher the apparent porosity, the greater the water vapor and oxygen permeability of films were (P < 0.05), which means gas molecules are permeating through pores. Puncture strength of films decreased as glycerol concentration increased, whereas puncture deformation was increased (P < 0.05). Lower glass transition temperature (Tg) observed as glycerol concentration increased, and Tg values of films were well fitted to Gordon-Taylor model as a function of glycerol mass fraction. Higher glycerol concentrations led to decrease of onset temperatures of weight losses, while weight loss increased. Infrared spectra of films showed similar backbone structure, but increasing glycerol concentration affected to peak intensity around 1000–1100 cm−1. All films had low percentage of degree of crystallinity. CMPC films showed lower contact angle than 65° and all films had hydrophilic surfaces. The surface morphology of films showed that films plasticized with 40% glycerol had the lowest roughness value (P < 0.05). Micrographs of films also showed porous surface structure as glycerol concentration increased, and these images supported the results of porosity, mechanical and barrier properties of films. It can be concluded from these results that glycerol at 40% concentration showed the best results when compared with the other two concentrations.

Similar content being viewed by others

References

da Rocha M, Loiko MR, Gautério GV, Tondo EC, Prentice C (2013) Influence of heating, protein and glycerol concentrations of film-forming solution on the film properties of Argentine anchovy (Engraulis anchoita) protein isolate. J Food Eng 116(3):666–673

Arfat YA, Benjakul S, Prodpran T, Osako K (2014) Development and characterisation of blend films based on fish protein isolate and fish skin gelatin. Food Hydrocoll 39:58–67

da Rocha M, Loiko MR, Tondo EC, Prentice C (2014) Physical, mechanical and antimicrobial properties of Argentine anchovy (Engraulis anchoita) protein films incorporated with organic acids. Food Hydrocoll 37:213–220

Gómez-Estaca J, Calvo MM, Sánchez-Faure A, Montero P, Gómez-Guillén MC (2015) Development, properties, and stability of antioxidant shrimp muscle protein films incorporating carotenoid-containing extracts from food by-products. LWT Food Sci Technol 64(1):189–196

Şahin A, Çarkcıoğlu E, Demirhan B, Candoğan K (2017) Chitosan edible coating and oxygen scavenger effects on modified atmosphere packaged sliced sucuk. J Food Process Preserv 41(6) e13213

Aşik E, Candoğan K (2014) Effects of chitosan coatings incorporated with garlic oil on quality characteristics of shrimp. J Food Qual 37(4):237–246

Emiroğlu ZK, Yemiş GP, Coşkun BK, Candoğan K (2010) Antimicrobial activity of soy edible films incorporated with thyme and oregano essential oils on fresh ground beef patties. Meat Sci 86(2):283–288

Tural S, Turhan S (2017) Effect of anchovy by-product protein coating incorporated with thyme essential oil on the shelf life of anchovy (Engraulis encrasicolus L.) fillets. Food Sci Biotechnol 26(5):1291–1299

Sablani SS, Dasse F, Bastarrachea L, Dhawan S, Hendrix KM, Min SC (2009) Apple peel-based edible film development using a high-pressure homogenization. J Food Sci 74(7):E372–E381

Pereira AGT, Ramos EM, Teixeira JT, Cardoso GP, Ramos AdLS, Fontes PR (2011) Effects of the addition of mechanically deboned poultry meat and collagen fibers on quality characteristics of frankfurter-type sausages. Meat Sci 89(4):519–525

Savadkoohi S, Shamsi K, Hoogenkamp H, Javadi A, Farahnaky A (2013) Mechanical and gelling properties of comminuted sausages containing chicken MDM. J Food Eng 117(3):255–262

Song DH, Choi JH, Choi YS, Kim HW, Hwang KE, Kim YJ, Ham YK, Kim CJ (2014) Effects of mechanically deboned chicken meat (MDCM) and collagen on the quality characteristics of semi-dried chicken jerky. Korean J Food Sci Anim Resour 34(6):727–735

Jin SK, Hwang JW, Moon S, Choi YJ, Kim GD, Jung EY, Yang HS (2014) The effects of mechanically deboned chicken hydrolysates on the characteristics of imitation crab stick. Korean J Food Sci Anim Resour 34(2):192–199

Saricaoglu FT, Turhan S (2017) Functional and film-forming properties of mechanically deboned chicken meat proteins. Int J Food Eng. https://doi.org/10.1515/ijfe-2017-0059

Zavareze EdR, Halal SLME, Marques e Silva R, Dias ARG, Prentice-Hernández C (2014) Mechanical, barrier and morphological properties of biodegradable films based on muscle and waste proteins from the whitemouth croaker (Micropogonias furnieri). J Food Process Preserv 38(4):1973–1981

AOAC (2000) Kjeltec nitorgen analysis. Association of Official Agricultural Chemists, Rockville

de Moura MR, Avena-Bustillos RJ, McHugh TH, Wood DF, Otoni CG, Mattoso LHC (2011) Miniaturization of cellulose fibers and effect of addition on the mechanical and barrier properties of hydroxypropyl methylcellulose films. J Food Eng 104(1):154–160

ASTM (2003) Standart test method for water vapor transmission of materials. American Society for Testing and Materials (ASTM), West Conshohocken

Avena-Bustillos RJ, Chiou B, Olsen CW, Bechtel PJ, Olson DA, McHugh TH, Gelation (2011) Oxygen permeability, and mechanical properties of mammalian and fish gelatin films. J Food Sci 76(7):E519–E524

ASTM (1995) Standard test method for oxygen gas transmission rate through plastic film and sheeting using a coulometric sensor. Annual book of American Standard Testing Methods USA. ASTM, West Conshohocken, pp 472–477

Chang C, Nickerson MT (2015) Effect of protein and glycerol concentration on the mechanical, optical, and water vapor barrier properties of canola protein isolate-based edible films. Food Sci Technol Int 21(1):33–44

Janjarasskul T, Krochta JM (2010) Edible packaging materials. Annu Rev Food Sci Technol 1(1):415–448

Daudt RM, Avena-Bustillos RJ, Williams T, Wood DF, Külkamp-Guerreiro IC, Marczak LDF, McHugh TH (2016) Comparative study on properties of edible films based on pinhão (Araucaria angustifolia) starch and flour. Food Hydrocoll 60:279–287

Otoni CG, Avena-Bustillos RJ, Olsen CW, Bilbao-Sáinz C, McHugh TH (2016) Mechanical and water barrier properties of isolated soy protein composite edible films as affected by carvacrol and cinnamaldehyde micro and nanoemulsions. Food Hydrocoll 57:72–79

Nuanmano S, Prodpran T, Benjakul S (2015) Potential use of gelatin hydrolysate as plasticizer in fish myofibrillar protein film. Food Hydrocoll 47:61–68

Nuthong P, Benjakul S, Prodpran T (2009) Effect of some factors and pretreatment on the properties of porcine plasma protein-based films. LWT Food Sci Technol 42(9):1545–1552

Kowalczyk D, Gustaw W, Zięba E, Lisiecki S, Stadnik J, Baraniak B (2016) Microstructure and functional properties of sorbitol-plasticized pea protein isolate emulsion films: effect of lipid type and concentration. Food Hydrocoll 60:353–363

Nawab A, Alam F, Haq MA, Lutfi Z, Hasnain A (2017) Mango kernel starch-gum composite films: physical, mechanical and barrier properties. Int J Biol Macromol 98:869–876

Jouki M, Tabatabaei Yazdi F, Mortazavi SA, Koocheki A (2013) Physical, barrier and antioxidant properties of a novel plasticized edible film from quince seed mucilage. Int J Biol Macromol 62:500–507

Donhowe G, Fennema O (1993) Water vapor and oxygen permeability of wax films. J Am Oil Chem Soc 70(9):867–873

Park HJ, Testin RF, Vergano PJ, Weller CL (1992) Factors affecting barrier and mechanical properties of protein-based edible, degradable films. Proceedings 53rd annual meeting of Instution of Food Technologists, New Orleans, 20–24 June 1992

Gontard N, Guilbert S, Cuq J-L (1993) Water and glycerol as plasticizers affect mechanical and water vapor barrier properties of an edible wheat gluten film. J Food Sci 58(1):206–211

Choi W-S, Han JH (2001) Physical and mechanical properties of pea-protein-based edible films. J Food Sci 66(2):319–322

Liu C-C, Tellez-Garay AM, Castell-Perez ME (2004) Physical and mechanical properties of peanut protein films. LWT Food Sci Technol 37(7):731–738

Yang L, Paulson AT (2000) Mechanical and water vapour barrier properties of edible gellan films. Food Res Int 33(7):563–570

Ramos ÓL, Reinas I, Silva SI, Fernandes JC, Cerqueira MA, Pereira RN, Vicente AA, Poças MF, Pintado ME, Malcata FX (2013) Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll 30(1):110–122

Barreto PLM, Pires ATN, Soldi V (2003) Thermal degradation of edible films based on milk proteins and gelatin in inert atmosphere. Polym Degrad Stab 79(1):147–152

Ghasemlou M, Khodaiyan F, Oromiehie A, Yarmand MS (2011) Characterization of edible emulsified films with low affinity to water based on kefiran and oleic acid. Int J Biol Macromol 49(3):378–384

Robertson GL (2012) Food packaging: principles and practice. CRC, New York

Jouki M, Mortazavi SA, Yazdi FT, Koocheki A (2014) Characterization of antioxidant–antibacterial quince seed mucilage films containing thyme essential oil. Carbohyd Polym 99(Supplement C):537–546

Kurt A, Kahyaoglu T (2014) Characterization of a new biodegradable edible film made from salep glucomannan. Carbohyd Polym 104(0):50–58

Colak BY, Gouanve F, Degraeve P, Espuche E, Prochazka F (2015) Study of the influences of film processing conditions and glycerol amount on the water sorption and gas barrier properties of novel sodium caseinate films. J Membr Sci 478:1–11

Sobral PJDA, Dos Santos JS, García FT (2005) Effect of protein and plasticizer concentrations in film forming solutions on physical properties of edible films based on muscle proteins of a Thai Tilapia. J Food Eng 70(1):93–100

Nuthong P, Benjakul S, Prodpran T (2009) Characterization of porcine plasma protein-based films as affected by pretreatment and cross-linking agents. Int J Biol Macromol 44(2):143–148

Guerrero P, de la Caba K (2010) Thermal and mechanical properties of soy protein films processed at different pH by compression. J Food Eng 100(2):261–269

Blanco-Pascual N, Fernández-Martín F, Montero P (2014) Jumbo squid (Dosidicus gigas) myofibrillar protein concentrate for edible packaging films and storage stability. LWT Food Sci Technol 55(2):543–550

Aewsiri T, Benjakul S, Visessanguan W (2009) Functional properties of gelatin from cuttlefish (Sepia pharaonis) skin as affected by bleaching using hydrogen peroxide. Food Chem 115(1):243–249

Bergo P, Sobral PJA (2007) Effects of plasticizer on physical properties of pigskin gelatin films. Food Hydrocoll 21(8):1285–1289

William RCV, Daniela CB, Sandriane P, Carlos P (2015) Preparation and characterization of nanocomposite film from Whitemuth croaker (Micropogonias furnieri) protein isolate modified with montmorillonite. Int Food Res J 22(3):1053–1058

Tanioka A, Miyasaka K, Ishikawa K (1976) Reconstitution of collagen-fold structure with stretching of gelatin film. Biopolymers 15(8):1505–1511

Rivero S, García MA, Pinotti A (2010) Correlations between structural, barrier, thermal and mechanical properties of plasticized gelatin films. Innov Food Sci Emerg Technol 11(2):369–375

Athamneh AI, Griffin M, Whaley M, Barone JR (2008) Conformational changes and molecular mobility in plasticized proteins. Biomacromol 9(11):3181–3187

Sharma L, Singh C (2016) Sesame protein based edible films: development and characterization. Food Hydrocoll 61:139–147

Galus S, Kadzińska J (2016) Whey protein edible films modified with almond and walnut oils. Food Hydrocoll 52:78–86

Khazaei N, Esmaiili M, Djomeh ZE, Ghasemlou M, Jouki M (2014) Characterization of new biodegradable edible film made from basil seed (Ocimum basilicum L.) gum. Carbohyd Polym 102:199–206

Antoniou J, Liu F, Majeed H, Qazi HJ, Zhong F (2014) Physicochemical and thermomechanical characterization of tara gum edible films: effect of polyols as plasticizers. Carbohyd Polym 111:359–365

Vogler EA (1998) Structure and reactivity of water at biomaterial surfaces. Adv Coll Interface Sci 74(1–3):69–117

Elofsson C, Dejmek P, Paulsson M, Burling H (1997) Atomic force microscopy studies on whey proteins. Int Dairy J 7(12):813–819

Mauer LJ, Smith DE, Labuza TP (2000) Water vapor permeability, mechanical, and structural properties of edible β-casein films. Int Dairy J 10(5–6):353–358

Farhan A, Hani NM (2017) Characterization of edible packaging films based on semi-refined kappa-carrageenan plasticized with glycerol and sorbitol. Food Hydrocoll 64:48–58

Gounga ME, Xu S-Y, Wang Z (2007) Whey protein isolate-based edible films as affected by protein concentration, glycerol ratio and pullulan addition in film formation. J Food Eng 83(4):521–530

Acknowledgements

This study was derived from Ph.D. thesis of first author, and was supported by Ondokuz Mayis University Research Foundation (Grant No. PYO.MUH.1904.15.006). Some parts of this study was performed at Healthy Processed Foods Research unit at Western Regional Research Center, Albany, CA (WRRC/ARS/USDA), while the first author was supported with a scholarship granted by The Scientific and Technological Research Council of Turkey (TUBITAK) (Grant No. 1059B141500356).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarıcaoğlu, F.T., Turhan, S. Physical, Chemical, Thermal and Microstructural Characterization of Edible Films from Mechanically Deboned Chicken Meat Proteins. J Polym Environ 27, 1071–1085 (2019). https://doi.org/10.1007/s10924-019-01410-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01410-5