Abstract

Self-binding ability of the pectin molecules was used to produce pectin films using the compression molding technique, as an alternative method to the high energy-demanding and solvent-using casting technique. Moreover, incorporation of fungal biomass and its effects on the properties of the films was studied. Pectin powder plasticized with 30% glycerol was subjected to heat compression molding (120 °C, 1.33 MPa, 10 min) yielding pectin films with tensile strength and elongation at break of 15.7 MPa and 5.5%, respectively. The filamentous fungus Rhizopus oryzae was cultivated using the water-soluble nutrients obtained from citrus waste and yielded a biomass containing 31% proteins and 20% lipids. Comparatively, the same strain was cultivated in a semi-synthetic medium resulting in a biomass with higher protein (60%) and lower lipid content (10%). SEM images showed addition of biomass yielded films with less debris compared to the pectin films. Incorporation of the low protein content biomass up to 15% did not significantly reduce the mechanical strength of the pectin films. In contrast, addition of protein-rich biomass (up to 20%) enhanced the tensile strength of the films (16.1–19.3 MPa). Lastly, the fungal biomass reduced the water vapor permeability of the pectin films.

Similar content being viewed by others

Introduction

Plastics, which are commonly derived from petroleum resources, harmfully affect the wild and human lives [1]. Accordingly, bioplastics have been suggested as one of the best alternatives for the conventional plastics. Along with plastics, residues of different industries are sometimes challenging and harmful to the environment. Citrus waste (CW), originated from citrus fruit, is an example of such residues [2, 3]. The majority of the CW is produced by the citrus fruit processing industry where half of the weight of the citrus fruit is converted into waste [3]. Low pH and high moisture content of CW prevent its landfilling according to the EU regulations [4], and the presence of essential oils is prejudicial to the composting and the biogas processes [2, 3]. Moreover, thermal treatments of CW yield low energy recovery due to the high moisture content [2, 3]. To overcome these difficulties, biological treatments of CW and production of value added products, e.g. by fermentation, has been proposed.

CW contains abundant amount of sugars, including poly-, di- and monosaccharides. Most polysaccharides (cellulose, hemicellulose, and pectin) are components of the peel of the CW, while the di- and monosaccharides (sucrose, glucose, and fructose) are present in the pulp. Satari et al. [5] reported fungal cultivation using a solution containing the free sugars extracted from CW, without the addition of any nutrients, in a bench scale airlift bioreactor. Hydrolysis of the structural polymers cellulose, hemicelluloses and pectin of CW, and ethanol production have also been reported [5,6,7].

Besides sugars, CW is also a major source for industrial production of pectin, the other abundant compound in the citrus peel. Pectin is the term used to describe a group of heteropolysaccharides naturally found in the cell wall of vascular plants which act as a cementing matrix in the cellulosic fibers [8]. The natural role of pectin in providing mechanical strength to the plant cell wall has encouraged the use of pectin as matrix in biocomposite materials. Pectin has a good potential to be used in food packaging films and biocomposite materials, which are renewable, biodegradable and biocompatible [9]. Pectin-based biocomposite films are usually produced by solution casting [10] in which pectin is dissolved in an aqueous acidic solution, and reinforcing materials are suspended in this solution. The solution is then casted over a smooth surface and dried to make a film [11]. Production of bioplastic films via solution casting method however has a high demand of energy which may avoid profitability of the process in large scales [12]. The molding method, on the other hand, usually has lower energy demand and processing time compared to the casting method, thus being preferred for industrial applications [13]. For non-thermoplastic biopolymers, such as proteins, heat compression molding has been applied to produce bioplastic items [14]. However, to the best of our knowledge, this technique has not been employed for production of pectin based bioplastics.

Blending of pectin with clay nanoparticles such as halloysite nanotubes [15, 16] and layered double hydroxides materials [17] positively affect the mechanical performances, improved thermal stability, and vapor barrier properties of the pectin films. Similarly, the blend of other biopolymers such as polysaccharides (e.g. starch, cellulose, and chitosan) [11], proteins, and lipids [18] were reported to improve the pectin films characteristics. For instance, in a review, Porta et al. [19] stated that addition of proteins, e.g. soy proteins, to pectin films not only brings a nutritional value to the films, but also increases the strength and improves the oxygen barrier characteristics. The improvements are caused by the strong interactions between the OH− and COO− groups of pectin and positively charged –NH groups of proteins. Lipids can form dipole-charge and dipole–dipole interactions with polar functional groups of pectin matrix and therefore, improve the characteristics of the pectin-based films [12, 18]. Furthermore, materials containing a mixture of several organic compounds, e.g. coffee ground, have been tested as filler for a pectin matrix with interesting results [20]. Fungal biomass is a rich source of different biopolymers. Improvement of the properties of the pectin films by blending the polymer with fungal biomass has not been investigated before.

The purpose of the current work was to apply a solvent-free compression molding method for production of bioplastic films from citrus peel derived pectin. Moreover, as another solution to CW challenges, free sugars and other water-soluble nutrients were extracted from CW and employed for cultivation of the filamentous fungus Rhizopus oryzae, in a pilot scale bubble column reactor. Incorporation of the fungal biomass to the pectin films was also investigated. Fungal biomass grown on a rich synthetic medium was used as a reference for comparison of the properties of the obtained films. SEM analyses were used to study the molecular interactions between the pectin and the fungal biomass components.

Materials and Methods

Materials

CW was kindly provided by Brämhults Juice AB (Borås, Sweden). For the production of pectin-based bioplastic films, citrus peel derived pectin (poly-d-galacturonic acid, ≥ 74%) from Sigma-Aldrich Inc. (St. Louis, MO, USA) was used. Anhydrous glycerol (analytical grade, 99%), from Scharlab S.L. (Barcelona, Spain), was used as plasticizer for the production of bioplastic films. Other chemicals and reagents used in this study were purchased from Sigma-Aldrich Inc. (St. Louis, MO, USA) unless stated otherwise.

Microorganism

Rhizopus oryzae (CCUG28958) used for biomass cultivation was acquired from the Culture Collection of the University of Gothenburg, Sweden. The strain was grown in agar plates (potato extract 4 g/L, dextrose 20 g/L, agar 15 g/L) for 5 days at 30 °C. The obtained plates were then kept at 5 °C until use for a maximum of 30 days. Spore suspension for inoculation was prepared by adding 20 mL of sterile water in a plate and gently stirring the liquid using a sterile L-shaped spreader.

Extraction of Citrus Waste Free Sugars (CWFS) and Nutrients

The soluble sugars and other soluble nutrients were extracted from CW according to Satari et al. [5] with minor modification. Briefly, CW in wet form (60 kg) was mixed with tap water (90 L) and left overnight. Thereafter, the mixture was subjected to liquid extraction in a fruit press machine (LANCMAN™ VSPIX120) equipped with a textile filter (pore size 3 mm). The citrus waste free sugars solution (CWFS) was collected and stored at 5 °C until use.

Cultivation in Bubble Column Reactor

Cultivation of R. oryzae was performed using different media, namely CWFS and a nutrient rich semi-synthetic medium [glucose (10 g/L), yeast extract (5.0 g/L), K2HPO4 (3.5 g/L), CaCl2·2H2O (1.0 g/L), MgSO4·7H2O (0.75 g/L), and (NH4)2SO4 (7.5 g/L)]. Sterilization of the liquid media was performed in an autoclave (Systec, Germany) at 121 °C for 20 min. R. oryzae inoculum was prepared in 1-L baffled Erlenmeyer flasks containing 300 mL of sterile CWFS medium or semi-synthetic medium at pH 5.5. These solutions were inoculated with 15 mL of spore suspension of R. oryzae and incubated in shaking water bath at 35 °C (for 24 h for semi-synthetic medium or 48–55 h for CWFS medium) to obtain enough fungal biomass for inoculation of 26 L bubble column bioreactor (Bioengineering, Switzerland).

Inoculum (1.5% v/v) was added to a 20-L plastic container containing the sterile medium (CWFS or semi-synthetic) to complete 20 L of working volume. In addition, 5 mL of antifoam 204 (Sigma-Aldrich Inc, MO, USA) was also added to the medium to prevent foam generation during the cultivation. This inoculated solution was manually transferred to the sterile bioreactor (sterilized by direct steam injection at 130 °C for 30 min) to start the cultivation, which was carried out at 35 °C and at an aeration rate of 1.5 vvm (volume of air per volume of medium per minute). The pH was adjusted to 5.4–5.5 at the beginning of the cultivation. The initial pH of CWFS was 3.6 and was increased to 5.5 using 5 M NaOH solution [5]. At the end of the cultivations, the broth was filtered through a kitchen sieve and the harvested solid was washed with tap water and stored at − 20 °C for further usage. As the media at the beginning of the cultivations contained no suspended solids, the collected solids were considered to be only fungal biomass.

The broth was analyzed in terms of lactic acid, glycerol, ethanol, glucose, and other sugars using a hydrogen-ion based ion-exchange column (Aminex HPX-87H, Bio-Rad, Hercules, CA, USA) installed in a high-performance liquid chromatography (HPLC) system at 60 °C, using 0.6 mL/min of 0.5 mM H2SO4 solution as the eluent. A refractive index detector (Waters 2414, USA) was used to identify and quantify the components.

Characterization of the Fungal Biomass

The standard Kjeldhal method (InKjel P digestor + Behrotest S1 distiller, Behr Labor-Technik, Germany) was adopted for analysis of protein content in the fungal biomass. For this analysis, the biomass was pre-dried at 70 °C overnight. Briefly, the protein content in the biomass was quantified in two steps, namely digestion (where the organic nitrogen content of biomass was converted into ammonium sulphate and water) and distillation (where ammonium hydroxide was collected as distillate through the reaction of (NH4)2SO4 with 10.7 M NaOH). The collected distillate was titrated with 0.1 M HCl to determine the protein concentration in fungal biomass (defined as 6.25 times the net nitrogen content of biomass) [21]. Sulfuric acid (Sigma-Aldrich Inc., MO, USA), Kjeldhal tablets (0.5 g CuSO4 + 5.0 g K2SO4; Thompsons and Capper LTD, UK), and antifoam tablets (0.97 g Na2SO4 + 0.03 g silicone antifoam; Thompsons and Capper LTD, UK) were used as reagents for biomass digestion.

Organic solvent extraction was used for lipid determination according to Majdejabbari et al. [22] with modification. The harvested biomass was lyophilized (Labconco: Kansas City, MO, USA) and milled to 0.2-mm size powder using a Rotor mill (Fritsch Pulverisette14, Fritsch Industries, Germany). Extraction was carried out by adding 25 mL of 0.4% (w/v) biomass suspension in water to 50 mL of organic solvent mix (containing 40% petroleum ether, 40% diethyl ether, and 20% absolute ethanol) in a 250 mL separating funnel. The content in the funnel was thoroughly mixed manually for 10 min and left still for phase separation. The organic phase was collected in pre-weighted glass beakers to determine the lipid concentration. The aqueous phase was subjected to two more extractions similar to the first one to guarantee the complete extraction of lipids. The beaker containing the organic phase of the three extractions was left overnight in a fume hood for evaporation of the liquid and further dried at 105 °C until constant weight. By weight difference, the amount of lipids was determined.

Solvent Free Method for Production of Pectin Films

The pectin films were produced using a solvent-free compression molding approach, which involved thermo-mechanical treatment of pectin. Pectin (Sigma-Aldrich Inc., St. Louis, MO, USA) was used with galacturonic acid ≥ 74.0%—dried basis, methoxy groups ≥ 6.7%—dried basis, and molecular weight of 30–100 kg/mol. Glycerol was used as plasticizer. Preliminary experiments (data not shown) indicated glycerol content (GC) of 30% (w/w) as the best concentration. Mixing of pectin powder with glycerol was carried out manually for 2 min with the help of a glass stirrer to get an uniform dough which was then formed into ball shape (total weight of 2.5 g) and stored in polyethylene (PE) bags overnight at room temperature. To prepare the films, the obtained pectin–glycerol blend was placed between two square-shaped high-density polyethylene sheets (12 cm × 12 cm) and placed in a Rondol 20 Ton molding press (Rondol Technologies Ltd, UK). The compression molding process was performed under operation conditions of 1.33 MPa and 120 °C. The heating plates were previously set at the working temperature and the sample was kept between them for 10 min. The sheets were then removed from the press and left at ambient temperature to cool for 5 min. The obtained pectin biofilms were stored in PE bags at room temperature for further characterization.

Pectin-based biomass films were also produced by incorporation of fungal biomass. The fungal biomass was lyophilized and milled (particle size < 0.2-mm) before mixing with pectin and glycerol. Biomass concentrations varied in the range of 0–35% of the total mixture. Glycerol content was kept at 30%. Pectin, fungal biomass, and glycerol were vigorously blended manually. A longer mixing step (5 min compare to 2 min for pectin films) was necessary to get a uniform dough material that was suitable for compression molding. Afterwards, the matrix was shaped into a ball (total weight of 2.5 g) and conditioned overnight at ambient temperature in PE bags to get better uniformity. Then, blends were subjected to compression molding to produce films. Figure 1 illustrates different steps in preparation of the pectin based films by compression molding approach.

Tensile Analyses

Tensile analyses, namely the yield point, the tensile strength (TS), the elongation at break (E%), and the Young’s modulus were performed to determine the mechanical properties of the films. These properties were measured using an Elastocon H10KT tensile testing machine (Elastocon AB, Sweden). The films were cut in dog-bone shaped testing specimens using a manual cutting press (EP 08, Elastocon AB, Sweden) equipped with a dog bone shape cutting die EP 04 ISO 32-7. The pectin films were subjected to the tensile examination with gauge length of 22 mm, load force of 100 N, gap between grips of 50 mm, and width of dog bone shape film specimen of 4 mm. QMat 5.41a-Dongle 4631 software processor was used to process the data. All film specimens were tested in triplicates.

Water Vapor Permeability Coefficient (WVPC)

Water vapor permeability coefficient (WVPC) was determined according to the ASTM E96 [23]. The pectin and pectin-biomass films were placed on the top of a pre-dried (at 70 °C, overnight) glass container (diameter of 32–50 mm depending on the film diameter) and sealed with a paraffin film. Prior to the film insertion, glass containers were filled with 50–100 g of distilled water, providing a distance between the tested film and the water surface of 2–3 cm. The weight of the entire setup, including the film, was measured (at time 0 h) and this was kept in a desiccator. The weight loss of the containers was measured every 24 h up to 5 days, and finally a graph of weight loss versus time was plotted which showed a linear behavior. The slope of the straight line was used for the WVPC calculation (in kg/s/m/Pa) according to Eq. (1).

where S is the slope of the plot (kg/s), A is the beaker mouth area (m2), ΔP is the vapor pressure difference (Pa) between the two sides (inside of glass container and desiccator) of the film and X is the film thickness (m) [24, 25]. The test was done in duplicates for each film.

Scanning Electron Microscopy (SEM)

Scanning electron microscopy (SIGMA VP FE-SEM, Carl Zeiss AG, Germany) analysis was conducted to study the morphology of the pectin based films. The micrographs were taken from surface and cross-section of the films. Before taking images from the surface, the samples were attached to a carbon tape and covered with gold. For cross-section imaging, samples were immersed in liquid nitrogen for 1 min, broken, and attached to a carbon tape placed on a stub. Then, the gold coating was performed before imaging. The images were collected at magnification of ×1000, energy of the beam 10 kV, and working distance of 6 mm for surface images, and at magnification of ×1500, energy of the beam 25 kV, and working distance of 10 mm for cross-section images.

Statistical Analyses

All experiments were carried out in duplicate. Data are reported as average ± standard deviation. Error bars in graphs indicate one standard deviation. Results were analysed using the software MINITAB® 17 Statistical Software (Minitab Inc., State College, PA, USA). Tukey tests were performed to determine statistical differences between results. A confidence interval of 95% was considered in all analyses.

Results and Discussions

Pectin-based bioplastic films have the potential to reduce the environmental footprint of human activity twofold: decreasing the negative effects of synthetic plastics and addressing the citrus waste management issue [26]. However, the solution casting method, the most-commonly used method for pectin film production, has a high demand of energy. In this work heat compression molding technique, with lower energy demand compared to casting [27, 28], was employed for production of pectin films. Furthermore, the potential of the fungal biomass for enhancement of the pectin films was investigated. The biomass was obtained by cultivation in water soluble nutrients of citrus waste [5]. Fungal biomass cultivated on a rich semi-synthetic medium was also used as a reference.

Self-binding Ability of Pectin and Production of Pectin Films

Thermo-triggered self-binding ability of proteins [28] and natural fibers [27] to produce binder-less objects has been reported. Under the thermo-mechanical treatments, proteins undergo disaggregation, denaturation, and dissociation reactions which can lead to the formation of new links and the aggregation of proteins to new forms [28]. Melting/glass transition as well as degradation reactions play roles in formation of new objects from natural fibers under thermo-mechanical treatments [27]. Plasticizers are often required to improve the processability and the mechanical properties by reducing the interactions between the polymers chains. Glycerol has been used to improve the properties of the protein bioplastics [28, 29]. The presence of water, moisture, has been reported to be necessary for production of cellulose bioplastics with good mechanical properties [27].

In this work the self-binding ability of pectin was investigated. Glycerol was used as a plasticizer. Pectin powder was mixed with glycerol to form a dough-like material. This material was then subjected to a heat compression molding process in similar conditions used for production of proteins bioplastics, namely, 120 °C and 1.33 MPa for 10 min. Higher tested temperature (150 °C) resulted in films with burnt edges and was not further used. The results confirmed the self-binding ability of pectin as shown in Fig. 2.

Optical photos of the pectin-based biofilms. a Pectin powder; b pectin (70%)–glycerol (30%) dough-like matrix; c pectin (70%)–glycerol (30%) bioplastic; d CWFS medium cultivated biomass (20–50%); e semi-synthetic medium cultivated biomass (15%)–pectin (55%); f semi-synthetic medium cultivated biomass (25%)–pectin (45%)

Using the solution casting method, Cavallaro et al. [15] prepared pectin films using polyethylene glycol (PEG) 20,000 as plasticizer at a weight ratio pectin/plasticizer of 4. Below this value, the obtained films were fragile and with several voids. In this study, glycerol concentrations higher than 30% resulted in very thin and mechanically weak films that were not suitable for further mechanical analyses (data not shown). On the other hand, pectin powder could not be properly homogenized using less than 30% glycerol. Thus, glycerol content of 30% was found to be the optimum value to prepare the pectin films.

Production of Fungal Biomass for Incorporation into Pectin Films

CWFS solution and a semi-synthetic medium were used for fungal cultivation in a 26-L bubble column bioreactor. The fungal biomass was harvested when the sugar concentration in the medium was close to zero. In CWFS medium, R. oryzae first consumed glucose. When the glucose level in the medium was low, consumption of other sugars, e.g. fructose and sucrose, was started. The profile of different components during the fungal fermentation is presented in Fig. 3. In average, 65–72 h was necessary for R. oryzae to completely assimilate the glucose (≈ 20 g/L) and ca. 10 g/L of other sugars present in the CWFS medium. Starting with 10 g/L glucose in semi-synthetic medium, the fungus needed 20 h for complete assimilation of the sugar. Therefore, the fungal exhibited comparable rates of glucose assimilation in these media. However, different profiles of fermentation byproducts were observed in these two media (Fig. 3).

The concentration of lactic acid and ethanol remained low during fungal cultivation in the CWFS medium. In the semi-synthetic medium, the obtained values for lactic acid and ethanol were 68 and 254 mg/g of consumed sugar at the end of cultivation, respectively (Table 1). Moreover, while in the semi-synthetic medium the production of glycerol was lower than the production of ethanol (0.12 g glycerol/g ethanol), the glycerol production was much higher than the ethanol production in CWFS medium (34.5 g glycerol/g ethanol). The result suggests different metabolic pathways were used in these media for glycerol production. This hypothesis is corroborated when taking into account the composition of the biomasses grown in the different media.

The protein concentration was only 310 mg/g biomass for the R. oryzae cultivated in CWFS medium while it was 600 mg/g biomass for the fungus cultivated in semi-synthetic medium. In contrast, the total lipid concentration in biomass was 200 mg/g for the fungus cultivated in CWFS medium, and only 100 mg/g for the fungus cultivated in semi-synthetic medium. The difference can be related to the different nitrogen composition of the media. The semi-synthetic medium was prepared with a total nitrogen content of 2.0 g/L, while nitrogen concentration was 1.3 g/L in CWFS medium, as determined by the Kjeldahl method, and no supplementation was used.

Protein synthesis in microorganisms is mostly influenced by the nitogen source in the cultivation medium. Microbial growth under nitrogen starvation, on the other hand, leads to accumulation of lipids, an adaptation necessary to survive under stress conditions. In such scenario, the tricarboxylic acid cycle is interrupted, causing accumulation of citrate in the cell. Citrate is then converted into oxaloacetate, which in turn is converted into malate. The last is further converted into pyruvate. All this reactions cause a net production of NADPH and acetyl-coenzyme A, which are used to produce fatty acids and triacylglycerides (TAGs) [30]. In fact, fatty acid metabolism is much more complex and involves several other reactions which are not part of this study [31]. The accumulation of lipid in the cells occurs via a dynamic equilibrium of fatty acid synthesis and degradation [31]. When degraded by lipases, TAGs are hydrolyzed into free fatty acids and glycerol [32]. Production of glycerol during the course of fungal cultivation in CWFS has probably been performed though a similar mechanism. Low ethanol yield and high lipid content in the biomass confirm this hypothesis. In semi-synthetic medium however, glycerol has been produced as a result of the alcoholic fermentation in order to maintain the cytosolic redox balance [33].

Incorporation of Fungal Biomass into Pectin Films

Pectin–fungal biomass films were prepared using 30% glycerol. The concentration of fungal biomass in the pectin films varied between 0 and 35%. Blends containing more than 35% of biomass were not suitable for compression molding (data not shown). Thickness of the obtained films was generally decreased by increasing the biomass concentration in the pectin-based films. The thickness of pectin films was 1.03 mm which was reduced to 0.2–0.4 mm (Table 2) in pectin–fungal biomass films. The biomass-incorporated pectin films were more flexible and softer than pure pectin films. Visually, incorporation of the fungal biomass resulted in darker and more opaque films (Fig. 2d–f).

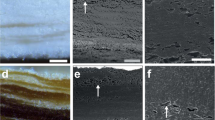

Scanning Electron Microscopy (SEM) of Pectin Based Films

The surface SEM images of the pectin based films are shown in Fig. 4. A bumpy, dense, and cracked surface with randomly distributed small particles (in white color) was observed in pure pectin film (Fig. 4a). The small particles on the surface of the pure pectin film were identified as non-homogenized pectin debris in the pectin–glycerol matrix. With addition of 10% of low-protein biomass (i.e. cultivated in CWFS medium), the small white particles disappeared and the film showed a coarse surface with few agglomerates (Fig. 4b). The obtained result indicates that biomass inclusion improves the uniformity of the pectin–glycerol matrix. Moreover, the SEM images indicate the fungal cells (that commonly present a cylindrical shape) were disrupted since no structure similar to the cells has been observed. Disruption of the cells means the intracellular components (e.g., proteins) have been released in the biofilm matrix and could interact with the pectin molecules. Pectin films with addition of 20% of protein-rich and low-protein biomasses presented more agglomerates (Fig. 4c, d, respectively) than the 10% low protein biomass film (Fig. 4b). These agglomerates, which were not present in the pure pectin film, indicate the incompatibility of the biomass components and pectin, leading to the formation of heterogeneous structures [34].

For a deeper analysis of the morphology, the cross-sectional images of pectin films were obtained and are presented in Fig. 5. Pure pectin film had a rugged structure with gaps, which irregularly appeared in the film. The film was organized like a group of closely packed surfaces (Fig. 5a). The lack of a solvent in the blend matrix might be the reason for the resulted structure and the poor homogenization of the pectin and glycerol. Interestingly, a more uniform texture was observed in the pectin films with addition of fungal biomass, with fewer gaps in the cross-sectional area compared to pectin film (Fig. 5b, c).

The pectin film containing low-protein biomass (Fig. 5c) showed a clumpy structure with few holes on the plane. The same structure was observed for the protein-rich biomass containing film with more structural discontinuities. This observation could be a result of the biomass composition (protein and lipid contents) and pectin interactions with biomass.

Moreover, a different internal organization was observed according to the film composition. The less-oriented network of the pectin film compared to the composite pectin films yielded greater thickness (Table 2), denser texture as well as cracks and gaps in the cross-section. Solution-casted pectin films showed a smoother morphology, according to Liu et al. [11] and Galus and Lenart [35], compared to the compression-molded pectin film in this study. This might be due to better homogenization of the materials in casting method compared to the compression molding technique. Solution casted soy-protein isolate films unmodified and modified with chitosan, however, showed rough and bubbly structure [34] similar to the biomass-containing pectin films of this study. Macroscopically, a rough, dense and brittle texture has been observed for a solution-casted pectin–soy flour protein (90–10%) film [11]. This is probably a consequence of the incompatibility of the pectin with proteins, which are one of the major ingredients of the fungal biomass.

Mechanical Properties of Films

The tensile strength (TS), elongation at break (E%), and Young’s modulus of the films are measured. Table 2 shows tensile properties and thickness values of pectin-based films at various blend ratios with fungal biomass obtained in this study as well as reference values from literature. All the films exhibited the same behavior, with the TS and yield strength at the same value; i.e., the rupture of the material happened during the elastic behavior. This means the stress versus strain graphs were straight lines whose linear coefficients represent the Young’s modulus. Pectin–glycerol blend yielded 1.03-mm thick films with TS of 15.7 MPa and E% of 5.5 (Table 2). The thickness of the film in a compression-molding process may be controlled by the concentration of plasticizer and the applied pressure. Kang et al. [36] produced pectin films using the solution casting method with lower thickness (0.17 mm), E% (3.45), and TS (0.153 MPa) compared to the film prepared in this study. Pectin–glycerol films prepared by Liu et al. [11] using the solution casting method yielded higher TS (17.0 MPa), and lower E% (2.5%) and thickness (0.15 mm). Similarly, Cavallaro et al. [15], produced much thinner films (0.06 mm) with higher TS (26 MPa) and lower E% (1.6%) using PEG 20,000 as plasticizer. Fishman et al. [37] produced pectin–glycerol films at the same composition of this study by extrusion method and got films with lower TS (9.9 MPa) and higher E% (10.9). When comparing the Young’s modulus, the film obtained in this study (298 MPa) had a value similar to the one obtained when preparing the pectin film by extrusion (201 MPa) [37]. On the other hand, the pectin films reported in the literature prepared by solution casting had much higher values for the Young’s modulus (1082 [11] and 2650 MPa [15]).

Promising results was obtained when the fungal biomass was incorporated in the pectin films up to 20%. In this range, the tensile yields of the low-protein biomass films were 15.9, 12.7, and 7.6 MPa for 10, 15, and 20% biomass ratio, respectively. The respective E% was 3.5, 2.5, and 3.8%. The films made with the protein-rich biomass exhibited tensile strength of 19.3, 19.2, and 16.1 MPa, and E% of 1.6, 1.9, and 4.3%, respectively. Comparing the results, the pectin films with protein-rich biomass demonstrated better mechanical properties than the pectin films with low protein content biomass. Therefore, the composition of the fungal biomass had a specific importance on the mechanical properties of the pectin films. Liu et al. [11] argued that, at the conditions they tested, the active aldehyde of the pectin and the primary amines of the tested proteins (soybean flour and fish skin gelatin) form cross-linking which can enhance the mechanical strength of the pectin–protein films. Young’s modulus of the pectin films with the protein-rich biomass increased more than fourfold. Values above 1000 MPa were obtained when using 10 or 15% biomass in the blend. This is the result of the increase in the TS and the decrease in the E%; i.e., the inclusion of the fungal biomass yielded more resistant films possibly because of the effect of the fungal biomass acting as fibers reinforcing the matrix. Nevertheless, loss of mechanical properties of the films was obtained when further increasing the biomass concentration in the blend matrix. This may be the result of the increase of the heterogeneous structures formed in the film when adding biomass to the pectin matrix, as observed by SEM images as well (Fig. 4). The values obtained for E% for the films containing or not fungal biomass were not statistically different (95% confidence interval).

For the pectin films with low-protein content biomass, up to 15% of biomass yielded films with higher TS and, above 15%, they showed almost similar values compared to the pectin films reported in the literature [37, 38]. Pectin films made in this study with the protein-rich biomass showed higher TS than the films made by compression molding with 30% GC and 70% whey protein [39], and solution casting pectin–starch film with 30% GC [38]. The films of this study also showed lower TS and higher E% than the films obtained by the solution casting of pectin–soy flour protein (10% protein) film [11]. This is in contrast to the results obtained by Sothornvit et al. [39] who obtained higher TS in the compression-molded whey protein isolate films compared to those produced using the solution casting method. They argued that the high heat and pressure applied during the molding process may have induced a higher rate of cross-linking of the protein chains compared to the heat denaturing that is used before solution casting of whey protein isolate films. The type of protein used and the presence of other substances in the biomass are possible explanations of the obtained results. The inclusion of the low-protein content fungal biomass in the films had little effect in the Young’s modulus as a result of the little changes produced in the TS and E% of the films. A maximum increase of approximately 80% in the Young’s modulus was obtained when using 15% of low-protein biomass in the film (533 MPa) compared to the pectin films without any fungal biomass (298 MPa).

The results of this study indicate that the removal of the solvent for production of pectin films can have a positive effect on the mechanical characteristics of the films and incorporation of fungal biomass can further improve these characteristics.

WVPC Analysis of Films

WVPC analysis was conducted in this study to determine the water vapor permeability of the films made with the protein-rich fungal biomass, which presented the most promising mechanical characteristics. High WVPC (kg/s/m/Pa) means the film has a poor resistance to the passage of water vapor. According to the obtained results (Fig. 6), the pure pectin film (0% biomass) showed the greatest values of WVPC (6.92 × 10−13 kg/s/m/Pa). However, it also presented the largest standard deviation. No statistical differences were observed in the WVPC values of pectin films containing protein-rich biomass (p > 0.05); the films showed values ranging from 2.35 × 10−13 (35% biomass content) to 3.58 × 10−13 kg/s/m/Pa (30% biomass content).

Overall, addition of biomass to the pectin films decreased the WVPC, hence fungal biomass may have increased the impermeabilization of the films to the passage of water vapor. Moreover, addition of biomass also reduced the thickness of the films and this may have contributed to the WVPC results. As observed in the SEM images of the cross-sectional area, addition of biomass in the matrix reduced the gaps in the structure of the films. Besides reducing the thickness, the removal of these gaps may have also contributed to the impermeabilization of the films, owing to the more compact structure. Nevertheless, further investigation is needed to determine the effectiveness of the biomass addition to the pectin films in reducing the WVPC.

All the films prepared in the current study using pectin demonstrated higher WVPC than the solution casting chitosan–carboxymethyl chitosan films (0.59 × 10−14–1.125 × 10−14 kg/s/m/Pa) from literature [24]. The pectin–fungal biomass films also presented higher WVPC than the solution casting films prepared from locust bean gum and plasticizer (polyethylene glycol 200, glycerol, propylene glycol, or sorbitol) which ranged between 1 × 10−14 and 6 × 10−14 kg/s/m/Pa [40].

Conclusion

Getting benefit of the self-binding capacity of pectin, compression molding has been proven to be an efficient method to produce pectin-based bioplastics, yielding films with interesting mechanical characteristics. Moreover, incorporation of protein-rich fungal biomass up to 15% decreased the presence of debris, increased the Young’s modulus, and decreased the water vapor permeability of the pectin films. R. oryzae is a very versatile microorganism and was able to grow in a medium with nutrients extracted from citrus waste without nutritional supplementation. The protein content of the fungal biomass positively favored the mechanical properties of the bioplastic.

References

Ackah R, Carboo D, Gyamfi ET (2012) Challenges of plastic waste disposal in Ghana: a case study of solid waste disposal sites in Accra. Elixir Manag Arts 49:9879–9885

Ruiz B, Flotats X (2014) Citrus essential oils and their influence on the anaerobic digestion process: an overview. Waste Manage 34:2063–2079

Lohrasbi M, Pourbafrani M, Niklasson C, Taherzadeh MJ (2010) Process design and economic analysis of a citrus waste biorefinery with biofuels and limonene as products. Bioresour Technol 101:7382–7388

European Commission (2008) Directive 2008/98/EC of the European parliament and of the council of 19 november 2008 on waste. Off J Eur Union L 312:22.11

Satari B, Karimi K, Taherzadeh M, Zamani A (2016) Co-production of fungal biomass derived constituents and ethanol from citrus wastes free sugars without auxiliary nutrients in airlift bioreactor. Int J Mol Sci 17:302

Lennartsson PR, Ylitervo P, Larsson C, Edebo L, Taherzadeh MJ (2012) Growth tolerance of zygomycetes Mucor indicus in orange peel hydrolysate without detoxification. Process Biochem 47:836–842

Talebnia F, Bafrani MP, Lundin M, Taherzadeh M (2007) Optimization study of citrus wastes saccharification by dilute acid hydrolysis. BioResources 3:108–122

Ochoa-Villarreal M, Aispuro-Hernández E, Vargas-Arispuro I, Martínez-Téllez M (2012) Plant cell wall polymers: function, structure and biological activity of their derivatives. In: Gomes AS (ed) Polymerization. IntechOpen, London, pp 63–86

Pilla S (2011) Handbook of bioplastics and biocomposites engineering applications. Wiley, New Jersey

Siemann U (2005) Solvent cast technology: a versatile tool for thin film production. In: Stribeck N, Smarsly B (eds) Scattering methods and the properties of polymer materials. Springer, Berlin, pp 307–316

Liu L, Liu L, Liu C-K, Fishman ML, Hicks KB (2007) Composite films from pectin and fish skin gelatin or soybean flour protein. J Agric Food Chem 55:2349–2355

Bátori V, Åkeson D, Zamani A, Taherzadeh MJ (2017) Pectin-based composites. In: Thakur VK, Thakur MK, Kessler MR (eds) Handbook of composites from renewable materials. Scrivener Publishing, Beverly, pp 487–517

Zubeldía F, Ansorena MR, Marcovich NE (2015) Wheat gluten films obtained by compression molding. Polym Test 43:68–77

Jerez A, Partal P, Martínez I, Gallegos C, Guerrero A (2007) Protein-based bioplastics: effect of thermo-mechanical processing. Rheol Acta 46:711–720

Cavallaro G, Lazzara G, Mioloto S (2013) Sustainable nanocomposites based on halloysite nanotubes and pectin/polyethylene glycol blend. Polym Degrad Stab 98:2529–2536

Makaremi M, Pasbakhsh P, Cavallaro G, Lazzara G, Aw YK, Lee SM, Milioto S (2017) Effect of morphology and size of halloysite nanotubes on functional pectin bionanocomposites for food packaging applications. ACS Appl Mater Interface 9:17476–17488

Gorrasi G, Bugatti V, Vittoria V (2012) Pectins filled with LDH-antimicrobial molecules: preparation, characterization and physical properties. Carbohydr Polym 89:132–137

Bonnaillie L, Zhang H, Akkurt S, Yam K, Tomasula P (2014) Casein films: the effects of formulation, environmental conditions and the addition of citric pectin on the structure and mechanical properties. Polymers 6:2018

Porta R, Mariniello L, Di Pierro P, Sorrentino A, Giosafatto CVL (2011) Transglutaminase crosslinked pectin- and chitosan-based edible films: a review. Crit Rev Food Sci 51:223–238

Cataldo VA, Cavallaro G, Lazzara G, Milioto S, Parisi F (2017) Coffee grounds as filler for pectin: green composites with competitive performances dependent on the UV irradiation. Carbohydr Polym 170:198–205

Mahboubi A, Ferreira JA, Taherzadeh MJ, Lennartsson PR (2017) Value-added products from dairy waste using edible fungi. Waste Manage 59:518–525

Majdejabbari S, Barghi H, Taherzadeh MJ (2011) Synthesis and properties of a novel biosuperabsorbent from alkali soluble Rhizomucor pusillus proteins. Appl Microbiol Biotechnol 92:1171–1177

Alves VD, Mali S, Beléia A, Grossmann MVE (2007) Effect of glycerol and amylose enrichment on cassava starch film properties. J Food Eng 78:941–946

Dayarian S, Zamani A, Moheb A, Masoomi M (2014) Physico-mechanical properties of films of chitosan, carboxymethyl chitosan, and their blends. J Polym Environ 22:409–416

Caner C, Vergano PJ, Wiles JL (1998) Chitosan film mechanical and permeation properties as affected by acid, plasticizer, and storage. J Food Sci 63:1049–1053

Bátori V, Jabbari M, Åkesson D, Lennartsson PR, Taherzadeh MJ, Zamani A (2017)Production of pectin-cellulose biofilms: a new approach for citrus waste recycling. Int J Polym Sci. https://doi.org/10.1155/2017/9732329

Pintiaux T, Viet D, Vandenbossche V, Rigal L, Rouilly A (2013) High pressure compression-molding of alpha-cellulose and effects of operating conditions. Materials (Basel) 6:2240–2261

Ciannamea EM, Stefani PM, Ruseckaite RA (2014) Physical and mechanical properties of compression molded and solution casting soybean protein concentrate based films. Food Hydrocoll 38:193–204

Gao C, Stading M, Wellner N, Parker ML, Noel TR, Mills ENC, Belton PS (2006) Plasticization of a protein-based film by glycerol: a spectroscopic, mechanical, and thermal study. J Agric Food Chem 54:4611–4616

Jin M, Slininger PJ, Dien BS, Waghmode S, Moser BR, Orjuela A, da Costa Sousa L, Balan V (2015) Microbial lipid-based lignocellulosic biorefinery: feasibility and challenges. Trends Biotechnol 33:43–54

Chen H, Hao G, Wang L, Wang H, Gu Z, Liu L, Zhang H, Chen W, Chen YQ (2015) Identification of a critical determinant that enables efficient fatty acid synthesis in oleaginous fungi. Sci Rep-UK 5:11247

Wongwatanapaiboon J, Malilas W, Ruangchainikom C, Thummadetsak G, Chulalaksananukul S, Marty A, Chulalaksananukul W (2016) Overexpression of Fusarium solani lipase in Pichia pastoris and its application in lipid degradation. Biotechnol Biotechnol Equip 30:885–893

Scanes KT, Hohrnann S, Prior BA (1998) Glycerol production by the yeast Saccharomyces cerevisiae and its relevance to wine: a review. S Afr J Enol Vitic 19:17–24

Li K, Jin S, Liu X, Chen H, He J, Li J (2017) Preparation and characterization of chitosan/soy protein isolate nanocomposite film reinforced by Cu nanoclusters. Polymers 9:247

Galus S, Lenart A (2013) Development and characterization of composite edible films based on sodium alginate and pectin. J Food Eng 115:459–465

Kang HJ, Jo C, Lee NY, Kwon JH, Byun MW (2005) A combination of gamma irradiation and CaCl2 immersion for a pectin-based biodegradable film. Carbohydr Polym 60:547–551

Fishman ML, Coffin DR, Onwulata CI, Konstance RP (2004) Extrusion of pectin and glycerol with various combinations of orange albedo and starch. Carbohydr Polym 57:401–413

Fishman ML, Coffin DR, Unruh JJ, Ly T (1996) Pectin/starch/glycerol films: blends or composites? J Macromol Sci A 33:639–654

Sothornvit R, Olsen CW, McHugh TH, Krochta JM (2007) Tensile properties of compression-molded whey protein sheets: determination of molding condition and glycerol-content effects and comparison with solution-cast films. J Food Eng 78:855–860

Bozdemir ÖA, Tutaş M (2003) Plasticiser effect on water vapour permeability properties of locust bean gum-based edible films. Turk J Chem 27:773–782

Acknowledgements

This work was financed by the Coordination for the Improvement of Higher Educational Personnel (Capes-Brazil).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gurram, R., Souza Filho, P.F., Taherzadeh, M.J. et al. A Solvent-Free Approach for Production of Films from Pectin and Fungal Biomass. J Polym Environ 26, 4282–4292 (2018). https://doi.org/10.1007/s10924-018-1300-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1300-x