Abstract

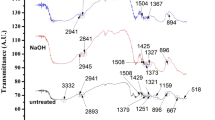

This work reports the influence of various treatments of pineapple leaf fibers (PALF) reinforced tapioca biopolymer (TBP) on the tensile properties. Three different treatments were selected, such as maleic anhydride polypropylene (MAPP) compatibility, maleic anhydride polyethylene (MAPE) compatibility and alkali treatment. Samples with 10% of PALF composition with different concentrations of MAPP and MAPE (1%, 3%, 5% and 7% by weight) and samples with three different treatments were prepared with different PALF compositions (10%, 20%, 30% and 40% by weight). Results revealed that PALF–TBP with 7% of MAPP showed the highest tensile strength and good interfacial adhesion with the matrix as evidenced by the Scanning electron microscopy analysis. Moreover, the chemical analysis by Fourier transforms infrared spectroscopy demonstrated that the MAPP had improved the PALF compatibility and matrix interfaces. Findings suggested that PALF–TBP composites have a great potential to be used for products in engineering applications.

Similar content being viewed by others

References

Balan AK, Parambil SM, Vakyath S, Velayudhan JT, Naduparambath S, Etathil P (2017) Coconut shell powder reinforced thermoplastic polyurethane/natural rubber blend-composites: effect of silane coupling agents on the mechanical and thermal properties of the composites. J Mater Sci 52:6712–6725

Chabba S, Netravali AN (2005) ‘Green’composites part 2: characterization of flax yarn and glutaraldehyde/poly(vinyl alcohol) modified soy protein concentrate composites. J Mater Sci 40:6275–6282

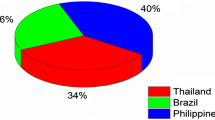

Jaafar J, Siregar JP, Oumer AN, Hamdan MHM, Tezara C, Salit MS (2018) Experimental investigation on performance of short pineapple leaf fiber reinforced tapioca biopolymer composites. BioResources 13:6341–6355

ASTM (1994) ASTM D5488-94de1 standard terminology of environmental labeling of packaging materials and packages (withdrawn 2002). ASTM International, West Conshohocken

Avérous L (2004) Biodegradable multiphase systems based on plasticized starch: a review. J Macromol Sci Polym Rev 44:231–274

Jamiluddin J, Siregar JP, Sulaiman A, Jalal KAA, Tezara C (2016) Study on properties of tapioca resin polymer. Int J Automot Mech Eng 13:3178–3189

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos B 42:856–873

Liu W, Misra M, Askeland P, Drzal LT, Mohanty AK (2005) ‘Green’composites from soy based plastic and pineapple leaf fiber: fabrication and properties evaluation. Polymer 46:2710–2721

Azwa Z, Yousif B, Manalo A, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442

Neto ARS, Araujo MA, Barboza RM, Fonseca AS, Tonoli GH, Souza FV, Mattoso LH, Marconcini JM (2015) Comparative study of 12 pineapple leaf fiber varieties for use as mechanical reinforcement in polymer composites. Ind Crops Prod 64:68–78

Neto ARS, Araujo MA, Souza FV, Mattoso LH, Marconcini JM (2013) Characterization and comparative evaluation of thermal, structural, chemical, mechanical and morphological properties of six pineapple leaf fiber varieties for use in composites. Ind Crops Prod 43:529–537

Nanthaya K, Taweechai A (2014) A new approach to ‘‘Greening’’ plastic composites using pineapple leaf waste for performance and cost effectiveness. Mater Des 55:292–299

Lee B-H, Kim H-J, Yu W-R (2009) Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties. Fiber Polym 10:83–90

Kim H-S, Kim S, Kim H-J, Yang H-S (2006) Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim Acta 451:181–188

Yang H-S, Wolcott MP, Kim H-S, Kim S, Kim H-J (2007) Effect of different compatibilizing agents on the mechanical properties of lignocellulosic material filled polyethylene bio-composites. Compos Struct 79:369–375

Siregar JP, Sapuan S, Rahman M, Zaman H (2010) The effect of alkali treatment on the mechanical properties of short pineapple leaf fibre (PALF) reinforced high impact polystyrene (HIPS) composites. J Food Agric Environ 8:1103–1108

Panyasart K, Chaiyut N, Amornsakchai T, Santawitee O (2014) Effect of surface treatment on the properties of pineapple leaf fibers reinforced polyamide 6 composites. Energy Procedia 56:406–413

George J, Janardhan R, Anand J, Bhagawan S, Thomas S (1996) Melt rheological behaviour of short pineapple fibre reinforced low density polyethylene composites. Polymer 37:5421–5431

Threepopnatkul P, Kaerkitcha N, Athipongarporn N (2009) Effect of surface treatment on performance of pineapple leaf fiber–polycarbonate composites. Compos B 40:628–632

Lopattananon N, Panawarangkul K, Sahakaro K, Ellis B (2006) Performance of pineapple leaf fiber–natural rubber composites: the effect of fiber surface treatments. J Appl Polym Sci 102:1974–1984

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Ibrahim NA, Hadithon KA, Abdan K (2010) Effect of fiber treatment on mechanical properties of kenaf fiber-ecoflex composites. J Reinf Plast Comp 29:2192–2198

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites. Compos Interface 15:169–191

Bachtiar D, Sapuan S, Hamdan M (2008) The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater Des 29:1285–1290

Yu T, Ren J, Li S, Yuan H, Li Y (2010) Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites. Compos A 41:499–505

Asim M, Jawaid M, Abdan K, Ishak MR (2016) Effect of alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. J Bionic Eng 13:426–435

Arib R, Sapuan S, Ahmad M, Paridah M, Zaman HK (2006) Mechanical properties of pineapple leaf fibre reinforced polypropylene composites. Mater Des 27:391–396

Siregar JP (2011) Effect of selected treatment on properties of pineapple leaf fibre reinforced high impact polystyrene composites. Thesis Doctor of Philosophy

Rana A, Mandal A, Mitra B, Jacobson R, Rowell R, Banerjee A (1998) Short jute fiber-reinforced polypropylene composites: effect of compatibilizer. J Appl Polym Sci 69:329–338

Mohanty S, Verma SK, Nayak SK (2006) Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos Sci Technol 66:538–547

Khalid M, Ali S, Abdullah L, Ratnam C, Choong ST (2006) Effect of MAPP as coupling agent on the mechanical properties of palm fiber empty fruit bunch and cellulose polypropylene biocomposites. Int J Eng Technol 3:79–84

Mohanty S, Nayak S, Verma S, Tripathy S (2004) Effect of MAPP as a coupling agent on the performance of jute–PP composites. J Reinf Plast Comp 23:625–637

Gassan J, Bledzki AK (1997) The influence of fiber-surface treatment on the mechanical properties of jute-polypropylene composites. Compos A 28:1001–1005

Ahmad I, Mosadeghzad Z, Daik R, Ramli A (2008) The effect of alkali treatment and filler size on the properties of sawdust/UPR composites based on recycled PET wastes. J Appl Polym Sci 109:3651–3658

Prachayawarakorn J, Chaiwatyothin S, Mueangta S, Hanchana A (2013) Effect of jute and kapok fibers on properties of thermoplastic cassava starch composites. Mater Des 47:309–315

Kang OL, Ramli N, Said M, Ahmad M, Yasir SM, Ariff A (2011) Kappaphycus alvarezii waste biomass: a potential biosorbent for chromium ions removal. J Environ Sci 23:918–922

Lomelí-Ramírez MG, Kestur SG, Manríquez-González R, Iwakiri S, de Muniz GB, Flores-Sahagun TS (2014) Bio-composites of cassava starch-green coconut fiber: part II—structure and properties. Carbohydr Polym 102:576–583

Ranganathan N, Oksman K, Nayak SK, Sain M (2016) Structure property relation of hybrid biocomposites based on jute, viscose and polypropylene: the effect of the fibre content and the length on the fracture toughness and the fatigue properties. Compos A 83:169–175

William FS, Hashemi J (2011) Foundation of materials science and engineering, 5th edn. McGraw-Hill Companies Inc, Singapore

Nadlene R, Sapuan SM, Jawaid M, Ishak MR, Yusriah L (2018) The effects of chemical treatment on the structural and thermal, physical, and mechanical and morphological properties of roselle fiber‐reinforced vinyl ester composites. Polym Compos 39:274–287

Mohanty A, Khan M, Hinrichsen G (2000) Influence of chemical surface modification on the properties of biodegradable jute fabrics—polyester amide composites. Compos A 31:143–150

Jumaidin R, Sapuan SM, Jawaid M, Ishak MR, Sahari J (2017) Effect of seaweed on mechanical, thermal, and biodegradation properties of thermoplastic sugar palm starch/agar composites. Int J Biol Macromol 99:265–273

Acknowledgements

The authors wish to thanks the Malaysian Ministry of Higher Education (Grant No.: RDU140120) for funding the research through the Fundamental Research Grant Scheme (FRGS) with Grant Number FRGS/1/2014/TK04/UMP/02/4. The authors are also obliged to express their gratitude to Universiti Malaysia Pahang for generously providing essential laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jaafar, J., Siregar, J.P., Piah, M.B.M. et al. Influence of Selected Treatment on Tensile Properties of Short Pineapple Leaf Fiber Reinforced Tapioca Resin Biopolymer Composites. J Polym Environ 26, 4271–4281 (2018). https://doi.org/10.1007/s10924-018-1296-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1296-2