Abstract

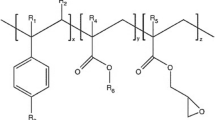

In this work, a series of reactive copolymers of glycidyl methacrylate (G), styrene (S) and acrylonitrile (AN), were synthesized through reversible addition-fragmentation chain transfer polymerization and evaluated as macromolecular chain extenders in reactive extrusion of recycled poly(ethylene terephthalate) (rPET). The results obtained indicate that the addition of the reactive copolymers as chain extenders modifies the chain conformation in rPET causing low crystallization rate and low crystallinity. The physical and rheological properties (melt flow and intrinsic viscosity) of chain-extended rPET improved, rendering better processability. rPET modified with polymeric chain extenders shows improved rheological properties (complex viscosity, storage and loss modulus) and also displays higher elongation at break and impact properties as the GMA content in the chain extenders increase.

Similar content being viewed by others

References

Srithep Y, Javadi A, Pilla S, Turng SL, Gong S, Clemons C, Peng J (2011) Processing and characterization of recycled poly(ethylene terephthalate) blends with chain extenders, thermoplastic elastomer, and/or poly(butylene adipate-co-terephthalate). J Polym Eng Sci 51:1023–1032

George N, Kurian T (2014) Recent developments in the chemical recycling of postconsumer poly(ethylene terephthalate). Ind Eng Chem Res 53:14185–14198

Farahat MS, Abdel-Azim AA, Abdel-Raowf ME (2000) Modified unsaturated polyester resins synthesized from poly(ethylene terephthalate) waste, 1. Synthesis and curing characteristics. Macromol Mater Eng 283:1–6

Carta D, Cao G, D’Angeli C (2003) Chemical recycling of poly(ethylene terephthalate)(pet) by hydrolysis and glycolysis. Environ Sci Pollut Res 10:390–394

Goje AS, Mishra S (2003) Chemical kinetics, simulation, and thermodynamics of glycolytic depolymerization of poly(ethylene terephthalate) waste with catalyst optimization for recycling of value added monomeric products. Macromol Mater Eng 288:326–336

Yamaye M, Hashime M, Yamamoto K, Kosugi K (2002) Chemical recycling of poly(ethylene terephthalate). 2. Preparation of terephthalohydroxamic acid and terephthalohydrazide. Ind Eng Chem Res 41:3993–3998

Scheirs J (1998) Polymer recycling: science, technology and applications. Wiley, London

Awaja F, Pavel D (2005) Recycling of PET. Eur Polym J 41:1453–1477

Raffa P, Coltelli MB, Savi S, Bianchi S, Castelvetro V (2012) Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: an experimental and modelling study. React Funct Polym 72:50–60

Villalobos M, Awojulu A, T (2006) Oligomeric chain extenders for economic reprocessing and recycling of condensation plastics. Greeley Energy 31:3227–3234

Coltelli MB, Maggiore ID, Savi S, Aglietto M, Ciardelli F (2005) Modified styrene-b-(ethylene-co-1-butene)-b-styrene triblock copolymer as compatibiliser precursor in polyethylene/poly(ethylene terephthalate) blends. Polym Degrad Stab 90:211–223

Coltelli MB, Aglietto M, Ciardelli F (2008) Influence of the transesterification catalyst structure on the reactive compatibilization and properties of poly(ethylene terephthalate) (PET)/dibutyl succinate functionalized poly(ethylene) blends. Eur Polym J 44:1512–1524

Coltelli MB, Bianchi S, Savi S, Liuzzo V, Aglietto M (2003) Metal catalysis to improve compatibility at PO/PET blends interfaces. Macromol Symp 204:227–236

Coltelli MB, Savi S (2004) A model study of Ti(OBu)4 catalyzed reactions during reactive blending of polyethylene (PE) and poly(ethylene terephthalate) (PET). Macromol Macromol Mater Eng 289:400–412

. Torres N, Robin J, Boutevin B (2001) Chemical modification of virgin and recycled poly(ethylene terephthalate) by adding of chain extenders during processing J. Appl Polym Sci 79:1816–1824

Xanthos M (2002) In: Fakirov S (ed) Handbook of thermoplastic polyesters. Wiley–VCH, Weinheim

Xanthos M, Young MW, Karayannidis GP, Bikiaris DN (2001) Reactive modification of polyethylene terephthalate with polyepoxides. Polym Eng Sci 41:643–655

Japon S, Boogh L, Leterrier Y, Manson JA (2000) Reactive processing of poly(ethylene terephthalate) modified with multifunctional epoxy-based additives. Polymer 41:5809–5818

Barner-Kowollik C (2008) Handbook of RAFT polymerization. Wiley-VCH, Weinheim

Moad G, Rizzardo E, Thang SH (2005) Living radical polymerization by the RAFT process. Aust J Chem 58:379–430

Moad G, Rizzardo E, Thang SH (2012) Living radical polymerization by the RAFT process: a third update. Aust J Chem 65:985–1036

Bai R, You Y, Pan Y (2001) 60Co γ-irradiation-initiated “living” free-radical polymerization in the presence of dibenzyl trithiocarbonate. Macromol Chem Phys Rapid Commun 22:315–319

American Society for Testing and Materials (1994) ASTM D 2857: standard test method for dilute solution viscosity of polymers. American Society for Testing and Materials, Philadelphia

Sanchéz NB, Dias ML, Pacheco E (2005) Comparative techniques for molecular weight evaluation of poly(ethylene terphthalate) (PET). Polym Test 24:688–693

Fakirov S (1994) Handbook of thermoplastics. Marcel Dekker, New York

Jabarin SA (1987) Crystallization kinetics of polyethylene terephthalate. I. Isothermal crystallization from the melt. J Appl Polym Sci 34:85–96

Ebeling B, Vana P (2011) Multiblock copolymers of styrene and butyl acrylate via polytrithiocarbonate-mediated RAFT polymerization. Polymers 3:719–739

Wang W, Hutchinson RA (2008) PLP/SEC/NMR study of free radical copolymerization of styrene and glycidyl methacrylate. Macromolecules 41:9011–9018

Brar AS, Pradhan DR (2003) Investigation of microstructure of the acrylonitrile-styrene-glycidyl methacrylate terpolymers by 1D and 2D NMR spectroscopy. J Appl Polym Sci 89:1779–1790

Shenoy AV, Saini DR (1986) Melt flow index: more than just a quality control parameter. Part I. Adv Polym Technol 6:1–58

Nascimento CR, Azuma Ch, Bretas R, Farah M, Dias ML (2010) Chain extension reaction in solid-state polymerization of recycled PET: the influence of 2,2-Bis-2-oxazoline and pyromellitic anhydride. J Appl Polym Sci 115:3177–3188

Turner SR (2004) Development of amorphous copolyesters based on 1,4-cyclohexanedimethanol. J Polym Sci Part A: Polym Chem 42:5847–5852

Härth M, Kaschta J, Schubert DW (2014) Shear and elongational flow properties of long-chain branched poly(ethylene terephthalates) and correlations to their molecular structure. Macromolecules 47:4471–4478

Nguyen QT, Japon S, Luciani A, Leterrier Y, Manson JA (2001) Molecular characterization and rheological properties of modified poly (ethylene terephthalate) obtained by reactive extrusion. Polym Eng Sci 41:1299–1309

Larson RG (1999) The structure and rheology of complex fluids. Oxford University Press, New York

Dealy JM, Wissbrun KF (1990) Melt rheology and its role in plastics processing. Van Nostrand Reinhold, New York

Xanthos M, Yilmazer U, Dey SK, Quintans J (2000) Melt viscoelasticity of polyethylene terephthalate resins for low density extrusion foaming. Polym Eng Sci 40:554–566

Trinkle S, Friedrich C (2001) Van Gurp-Palmen-plot: a way to characterize polydispersity of linear polymers. Rheol Acta 40:322–328

Trinkle S, Walter P, Friedrich C (2002) Van Gurp-Palmen plot II: classification of long chain branched polymers by their topology. Rheol Acta 41:103–113

Yang Z, Xin Ch, Mughal W, Li X, He Y (2017) High-melt-elasticity poly(ethylene terephthalate) produced by reactive extrusion with a multi-functional epoxide for foaming. J Appl Polym Sci 135:45805–45814

Chanda M, Roy SK (2006) Plastics technology handbook, 2d. edn. CRC Press, Boca Raton

Peacock AJ (2000) Handbook of polyethylene: structures: properties, and applications. Marcel Dekker, Inc., New York

Pegoretti A, Penati A (2004) Recycled poly(ethylene terephthalate) and its short glass fibres composites: effect of hygrothermal aging on the thermo-mechanical behavior. Polymer 45:7995–8004

Acknowledgements

We acknowledge the technical support of Francisco Méndez and Luis Reyes from Resirene Applications Laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benvenuta Tapia, J.J., Hernández Valdez, M., Cerna Cortez, J. et al. Improving the Rheological and Mechanical Properties of Recycled PET Modified by Macromolecular Chain Extenders Synthesized by Controlled Radical Polymerization. J Polym Environ 26, 4221–4232 (2018). https://doi.org/10.1007/s10924-018-1294-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1294-4