Abstract

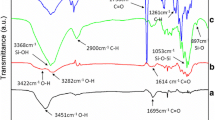

The objective of this study was to investigate the properties of poly(vinyl alcohol)/chitosan nanocomposite films reinforced with different concentration of amorphous LCNFs. The properties analyzed were morphological, physical, chemical, thermal, biological, and mechanical characteristics. Oil palm empty fruit bunch LCNFs obtained from multi-mechanical stages were more dominated by amorphous region than crystalline part. Varied film thickness, swelling degree, and transparency of PVA/chitosan nanocomposite films reinforced with amorphous part were produced. Aggregated LCNFs, which reinforced PVA/chitosan polymer blends, resulted in irregular, rough, and uneven external surfaces as well as protrusions. Based on XRD analysis, there were two or three imperative peaks that indicated the presence of crystalline states. The increase in LCNFs concentration above 0.5% to PVA/chitosan polymer blends led to the decrease in crystallinity index of the films. A noticeable alteration of FTIR spectra, which included wavenumber and intensity, was obviously observed along with the inclusion of amorphous LCNFs. That indicated that a good miscibility between amorphous LCNFs and PVA/chitosan polymer blend generated chemical interaction of those polymers during physical blending. Reinforcement of PVA/chitosan polymer blends with amorphous LCNFs influenced the changes of Tg (glass transition temperature), Tm (melting point temperature), and Tmax (maximum degradation temperature). Three thermal phases of PVA/chitosan/LCNFs nanocomposite films were also observed, including absorbed moisture evaporation, PVA and chitosan polymer backbone structural degradation and LCNFs pyrolysis, and by-products degradation of these polymers. The addition of LCNFs 0.5% had the highest tensile strength and the addition of LCNFs above 0.5% decreased the strength. The incorporation of OPEFB LCNFs did not show anti-microbial and anti-fungal properties of the films. The addition of amorphous LCNFs 0.5% into PVA/chitosan polymer blends resulted in regular and smooth external surfaces, enhanced tensile strength, increased crystallinity index, and enhanced thermal stability of the films.

Similar content being viewed by others

References

Choo K, Ching CY, Chuah CH, Julai S, Liou NS (2016) Preparation and characterization of polyvinyl alcohol-chitosan composite films reinforced with cellulose nanofiber. Materials 9:644–660

Azizi S, Ahmad MB, Ibrahim NA, Hussein MZ, Namvar F (2014) Preparation and properties of poly(vinyl alcohol)/chitosan blend bio-nanocomposites reinforced by cellulose nanocrystals. Chin J Polym Sci 201532:1620–1627

Charernsriwilaiwat N, Rojanarata T, Ngawhirunpat T, Opanasopit P (2012) Electrospun chitosan/polyvinyl alcohol nanofibre mats for wound healing. Int Wound J 11(2):215–222

Mahmoodi NM, Shourijeh ZM (2015) Preparation of PVA-chitosan blend nanofiber and its dye removal ability from colored wastewater. Fibers Polym 16:1861–1869

Kermani AS, Esfandiary N (2016) Synthesis and characterization of new biodegradable chitosan/polyvinyl alcohol/cellulose nanocomposite. Adv Nanopart 5:18–26

Azizi S, Ahmad MB, Hussein MZ, Ibrahim NA, Namvar F (2014) Preparation and properties of poly(vinyl alcohol)/chitosan blend bionanocomposites reinforced with cellulose nanocrystals/ZnO–Ag multifunctional nanosized filler. Int J Nanomed 9:1909–1917

Parparita E, Natalia C, Cheaburu C (2012) Vasile. Morphological, thermal and rheological characterization of polyvinyl alcohol/chitosan blends. Cellul Chem Technol 46:571 – 581

Rescignano N, Fortunatin E, Montesano S, Emiliani C, Kenny JM, Martino S, Armentano I (2014) PVA bio-nanocomposites: a new take-off using cellulose nanocrystals and PLGA nanoparticles. Carbohydr Polym 99:47–58

Priya B, Gupta VK, Pathania D, Singha AS (2014) Synthesis, characterization and antibacterial activity of biodegradablestarch/PVA composite films reinforced with cellulosic fibre. Carbohydr Polym 109:171–179

Li W, Wu Q, Zhao X, Huang Z, Cao J, Li J, Liu S (2014) Enhanced thermal and mechanical properties of PVA compositesformed with filamentous nanocellulose fibrils. Carbohydr Polym 113:403–410

Mandal A, Chakrabarty D (2015) Characterization of nanocellulose reinforced semi-interpenetrating polymer network of poly(vinyl alcohol) & polyacrylamide composite films. Carbohydr Polym 134:240–250

Panaitescu DM, Frone AN, Ghiurea M, Chiulan I (2015) Influence of storage conditions on starch/PVA films containing cellulose nanofibers. Ind Crops Prod 70:170–177

Hafdani FN, Sadhegenia NA (2011) Review on application of chitosan as a natural antimicrobial. Int J Med Health Biomed Bioeng Pharm Eng 5:2011

Pavaloiu RD, Guzun AS, Stroescu M, Jinga SI, Dobre T (2014) Composite films of poly(vinyl alcohol)-chitosan-bacterial cellulose for drug controlled release. Int J Biol Macromol 68:117–124

Azeredo HMC, Mattoso LHC, Bustillos RJA, Filho GC, Munford ML, Wood D, Mchugh TH (2010) Nanocellulose reinforced chitosan composite films as affected by nanofiller loading and plasticizer content. J Food Sci 75:1

Park SC, Nam JP, Kim JH, Kim YM, Nah JW, Jang MK (2015) Antimicrobial action of water-soluble β -chitosan against clinical multi-drug resistant bacteria. Int J Mol Sci 16:7995–8007

Rafique A, Zia KM, Zuber M, Tabasum S, Rehman S (2016) Chitosan functionalized poly (vinyl alcohol) for prospects biomedical and industrial applications: a review. Int J Biol Macromol 87:141–154

Zhou Y, Fu S, Zhang L, Zhan H, Levit MV (2014) Use of carboxylated cellulose nanofibrils-filled magnetic chitosanhydrogel beads as adsorbents for Pb(II). Carbohydr Polym 101:75–82

Solikhin A, Hadi YS, Massijaya MY, Nikmatin S (2016) Basic properties of oven-heat treated oil palm empty fruit bunch stalk fibers. Bioresources 11:2224–2237

Nikmatin S (2012) Bionanocomposite of polypropylene reinforced cellulose nanoparticles biomass of rattan synthetic substitute composite by motorcycle. Doctoral dissertation, Bogor Agricultural Univesity, Bogor

Osong SH (2014) Mechanical pulp based nano-ligno-cellulose production, characterisation and their effect on paper properties. Master thesis, Mid Sweden University, Sundsvall

Kojima Y, Isa A, Kobori H, Suzuki S, Ito H, Makise R, Okamoto M (2014) Evaluation of binding effects in wood flour board containing ligno-cellulose nanofibers. Materials 7:6853–6864

Iwamoto S, Yamamoto S, Lee S-H, Ito H, Endo T (2015) Mechanical and thermal properties of polypropylene composites reinforced with lignocellulose nanofibers dried in melted ethylene-butene copolymer. Materials 7:6919–6929

Iwamoto S, Endo T (2015T. Endo. 3 nm thick lignocellulose nanofibers obtained from esterified wood with maleic anhydride. ACS Macro Lett 4:80–83

Iwamoto S, Yamamoto S, Lee S-H, Endo T (2014) Solid-state shear pulverization as effective treatment for dispersing lignocellulose nanofibers in polypropylene composites. Cellulose 21(3):1573–1580

Solikhin A, Hadi YS, Massijaya MY, Nikmatin S (2016) Novel isolation of empty fruit bunch lignocellulose nanofibers using different vibration milling times-assisted multimechanical stages. Waste Biomass Valoriz 8(7):2451–2462

Kang Y, Ahn Y, Lee SH, Hong JH, Ku MK, Kim H (2013) Lignocellulosic nanofiber prepared by alkali treatment and electrospinning using ionic liquid. Fiber Polym 14:530–536

Osong SH, Norgren S. Engstrand P, Lundberg M, Hansen P (2014) Crill: a novel technique to characterize nano – ligno – cellulose. Nord Pulp Pap Res J 29:190–194

Frone AN, Panaitescu DM, Donescu D, Spataru CI, Radovici C, Trusca R, Somoghi R (2011) Preparation and characterization of PVA composite with cellulose nanofibers obtained by ultrasonication. Bioresources 6:487–512

Hu Y, Li D, Deng Q, Wang Y, Lin D (2012) Novel poly(vinyl alcohol) nanocomposites reinforced with nano cellulose fibrils isolated from plants by mechanochemical treatment. Appl Mech Mater 174–177:870–876

Fortunati E, Puglia D, Luzi F, Santulli C, Kenny JM, Torre L (2013) Binary PVA bio-nanocomposites containing cellulose nanocrystals extracted from different natural sources: Part I. Carbohydr Polym 97:825–836

Kakroodi AR, Cheng S, Sain M, Asiri A (2014) Mechanical, thermal, and morphological properties of nanocomposites based on polyvinyl alcohol and cellulose nanofiber from Aloe vera rind. J Nanomater 2014:139

Ching YC, Rahman A, Ching KY, Sukiman NL, Chuah CH (2015) Preparation and characterization of polyvinyl alcohol based composite reinforced with nanocellulose and nanosilica. Bioresouces 10:3364–3377

Sirviö JA, Honkaniemi S, Visanko M, Liimatainen H (2015) Composite films of polyvinyl alcohol and bifunctional crosslinking cellulose nanocrystals. ACS Appl Mater Interfaces 7(35):1969–19699

Dehnad D, Djomeh ZE, Mirzaei H, Jafari SM, Dadashi S (2014) Optimization of physical and mechanical properties for chitosan–nanocellulose biocomposites. Carbohydr Polym 105:222–228

Celebi H, Kurt A (2015) Effects of processing on the properties of chitosan/cellulose nanocrystal films. Carbohydr Polym 133:284–293

Zeid RAE, Hassan EA, Bettaieb F, Khiari R, Hassan M (2015) Use of cellulose and oxidized cellulose nanocrystals from olive stones in chitosan bionanocomposites. J Nanomater 16(1):172

Bajpai SK, Chand N, Ahuja S (2015) Investigation of curcumin release from chitosan/cellulose microcrystals (CMC) antimicrobial films. Int J Biol Macromol 79:40–448

Solikhin A, Hadi YS, Massijaya MY, Nikmatin S (2016) Morphological and chemo-thermal changes of oven-heat treated oil palm empty fruit bunch fibers during dry disk milling. J Indian Acad Wood Sci 14(1):1–17

Kiziltas EE, Kiziltas A, Bollind SC, Gardner DJ (2015) Preparation and characterization of transparent PMMA-cellulose-based nanocomposites. Carbohydr Polym 127:381–389

Hamid SBA, Zain SK, Das R, Centi G (2015) Synergic effect of tungstophosphoric acid and sonication for rapid synthesis of crystalline nanocellulose. Carbohydr Polym 138:349 – 355

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 6:220 – 227

Guimaraes M, Botarom VR, Novack KM, Teixeira FG, Tonoli GHD (2015) Starch/PVA – based nanocomposites reinforced with bamboo nanofibrils. Ind Crops Prod 70:72–83

Reid SM, Villalobos M, Cranston DE (2016) Cellulose nanocrystal interactions probed by thin film swelling to predict dispersibility. Nanoscale 8:12247–12257

Virtanen S, Vartianen J, Setala H, Tammelin T, Vouti S (2014) Modified nanofibrillated cellulose–polyvinyl alcohol films with improved mechanical performance. RSC Adv 4(22):11343–11350

Zhou YM, Fu YS, Zheng LM, Zhan HY (2012) Effect of nanocellulose isolation techniques on the formation of reinforced poly(vinyl alcohol) nanocomposite films. Express Polym Lett 6:794–804

Tripathi S, Mehrotra GK, Dutta PK (2010) Preparation and physicochemical evaluation of chitosan/poly(vinyl alcohol)/pectin ternary film for food packaging applications. Carbohydr Polym 72:711–716

Zhang Y, Huang X, Duan B, Wu L, Li S, Yuan X (2007) Preparation of electrospun chitosan/poly(vinyl alcohol) membranes. Colloid Polym Sci 285:855 – 863

Zheng H, Du Z, Yu J, Huang R, Zhang L (2007) Preparation and characterization of chitosan/poly(vinyl alcohol) blend fibers. J Appl Polym Sci 80:2558 – 2565

Mandal A, Chakrabarty D (2015) Studies on the mechanical, thermal, morphological and barrier properties of nanocomposites based on poly(vinyl alcohol) and nanocellulose from sugarcane bagasse. J Ind Eng Chem 20:462 – 473

Lee S-Y, Mohan DJ, Kang I-A, Doh G-H, Lee S, Han SO (2009) Nanocellulose reinforced PVA composite films: effects of acid treatmentand filler loading. Fibers Polym 10:77–82

Santos C, Silva CJ, Buttel Z, Guimaraes R, Pereira SB, Tamagnini P, Zille A (2014) Preparation and characterization of polysaccharides/PVA blend nanofibrous membranes by electrospinning method. Carbohydr Polym 99:584–592

Ostadhossein F, Mahmoudi N, Cid MG, Tamjid E, Martos FJN, Cuadrado BS, Paniza JML, Simchi A (2015) Development of chitosan/bacterial cellulose composite films containing nanodiamonds as a potential flexibel platform for wound dressing. Materials 8:6401 – 6418

Li CM, Wu Q, Song K, Cheng HN, Suzuki S, Lei T (2016) Chitin nanofibers as reinforcing and antimicrobial agents in carboxymethyl cellulose films: influence of partial deacetylation. ACS Sustain Chem Eng 4:4385 – 4395

Cho M-J, Park B-D (2011) Tensile and thermal properties of nanocellulose-reinforced poly(vinyl alcohol) nanocomposites. J Ind Eng Chem 17:36–40

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–57

Acknowledgements

We sincerely acknowledge to the Doctoral Programme for Outstanding Undergraduate Students (PDSU) Secretariat, because of the greatest financial support [Grant No. 180/SP2H/LT/DRM/III/2016 Directorate of Higher Education (DIKTI), Ministry of Research, Technology, and Higher Education (Menristekdikti), Republic of Indonesia]. We also thank some laboratory staffs at PT Perkebunan Kelapa Sawit Nusantara VIII, Shizuoka University, Indonesian Institute of Sciences, Forest Products Research and Development Centre, Bogor Agricultural University, Bandung Institute of Technology, Gadjah Mada University, Universitas Indonesia, and National Nuclear Energy Agency for the assistance of this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Solikhin, A., Hadi, Y.S., Massijaya, M.Y. et al. Properties of Poly(Vinyl Alcohol)/Chitosan Nanocomposite Films Reinforced with Oil Palm Empty Fruit Bunch Amorphous Lignocellulose Nanofibers. J Polym Environ 26, 3316–3333 (2018). https://doi.org/10.1007/s10924-018-1215-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1215-6