Abstract

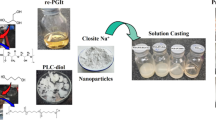

Biodegradable polyester polyol was synthesized from oleochemical glycerol monostearate (GMS) and glutaric acid under a non-catalyzed and solvent-free polycondensation method. The chemical structure of GMS-derived polyester polyol (GPP) was elucidated by FTIR, 1H and 13C NMR, and molecular weight of GPP was characterized by GPC. The synthesized GPP with acid value of 3.03 mg KOH/g sample, hydroxyl value of 115.72 mg KOH/g sample and Mn of 1345 g/mol was incorporated with polyethylene glycol (PEG) and polycaprolactone diol (PCL diol) to produce a water-blown porous polyurethane system via one-shot foaming method. The polyurethanes were optimized by evaluating glycerol as a crosslinker, silicone surfactant and water blowing agent on tensile properties of polyurethanes. All polyurethanes underwent structural change, and crystalline hard segments of polyurethanes were shifted to higher temperature suggested that hard segments undergone re-ordering process during enzymatic treatment. In terms of biocompatibility, polyurethane scaffold produced by reacting 100% w/w of GPP with isophorone diisocyanate and additives showed the highest cells viability of 3T3 mouse fibroblast (94%, day 1), and MG63 human osteosarcoma (107%, day 1) and better cell adhesion as compared to reference polyurethane produced by only PEG and PCL diol (3T3 cell viability: 8%; MG63 cell viability: 2%). The current work demonstrated GPP synthesized from renewable and environmental friendly resources produced polyurethanes that allows improvement in physico-chemical, mechanical and biocompatibility properties. By blending with increasing content of GPP, the water-blown porous polyurethane scaffold has shown great potential as biomaterial for soft and hard tissue engineering.

Similar content being viewed by others

References

Dang LN, Le Hoang S, Malin M, Weisser J, Walter T, Schnabelrauch M, Seppälä J (2016) Eur Polym J 81:129–137

Jiang X, Li J, Ding M, Tan H, Ling Q, Zhong Y, Fu Q (2007) Eur Polym J 43:1838–1846

Jiang X, Yu F, Wang Z, Li J, Tan H, Ding M, Fu Q (2010) J Biomater Sci 21:1637–1652

Qu WQ, Xia YR, Jiang LJ, Zhang LW, Hou ZS (2016) Chin Chem Lett 27:135–138

Sartori S, Boffito M, Serafini P, Caporale A, Silvestri A, Bernardi E (2013) React Funct Polym 73:1366–1376

Chen R, Huang C, Ke Q, He C, Wang H, Mo X (2010) Colloids Surf B Biointerfaces 79:315–325

Chiono V, Mozetic P, Boffito M, Sartori S, Gioffredi E, Silvestri A (2014) Interface Focus 4:20130045

Ruan C, Hu N, Hu Y, Jiang L, Cai Q, Wang H (2014) Polymer 55:1020–1027

Guelcher SA, Gallagher KM, Didier JE, Klinedinst DB, Doctor JS, Goldstein AS (2005) Acta Biomater 1:471–484

Barrioni BR, de Carvalho SM, Oréfice RL, de Oliveira AAR, de Magalhães Pereira M (2015) Mater Sci Eng C 52:22–30

Asefnejad A, Khorasani MT, Behnamghader A, Farsadzadeh B, Bonakdar S (2011) Int J Nanomed 6:2375–2384

Liu H, Gao Z, Hu X, Wang Z, Su T, Yang L, Yan S (2016) J Polym Environ 2:156–164

Panwiriyarat W, Tanrattanakul V, Pilard JF, Pasetto P, Khaokong C (2013) J Polym Environ 21:807–816

Wang Z, Yu L, Ding M, Tan H, Li J, Fu Q (2011) Polym Chem 2:601–607

Kupra V, Vojtova L, Fohlerova Z, Jancar J (2016) Exp Polym Lett 6:479–492

Sun LJ, Yao C, Zheng HF, Lin J (2012) Chin Chem Lett 23:919–922

Noor NM, Ismail TNMT, Kian YS, Hassan HA (2013) J Oil Palm Res 25:92–99

Badri KH, Ahmad SH, Zakaria S (2001) J Appl Polym Sci 81:384–389

Hazmi ASA, Aung MM, Abdullah LC, Salleh MZ, Mahmood MH (2013) Ind Crops Prod 50:563–567

Sahoo S, Kalita H, Mohanty S, Nayak SK (2017) J Polym Environ 1–12

Zieleniewska M, Auguścik M, Prociak A, Rojek P, Ryszkowska J (2014) Poly Degrad Stab 108:241–249

Horák P, Beneš H (2015) Polimery 60

Bakhshi H, Yeganeh H, Mehdipour-Ataei S, Shokrgozar MA, Yari A, Saeedi-Eslami SN (2013) Mater Sci Eng C Mater Biol Appl 33:153–164

Ng WS, Lee CS, Chuah CH, Cheng SF (2017) Ind Crops Prod 97:65–78

Zhang S, Xiang A, Tian H, Rajulu AV (2016) J Polym Environ 1–8

Hafeman AE, Li B, Yoshii T, Zienkiewicz K, Davidson JM, Guelcher SA (2008) Pharm Res 25:2387–2399

ASTM Standard D3574–11, 2008, Standard test methods for flexible cellular materials – slab, bonded, and molded urethane foams, ASTM International, West Conshohocken, PA, 2008, pp 3574–3508

Skrobot J, Ignaczak W, El Fray M (2015) Polym Degrad Stab 120:368–376

Podporska-Carroll J, Ip JW, Gogolewski S (2014) Acta Biomater 10:2781–2791

Mihai R, Florescu IP, Coroiu V, Oancea A, Lungu M (2011) J Med Life 4:250–255

Yu CC, Lee YS, Cheon BS, Lee SH (2003) Bull Korean Chem Soc 24:1229–1231

Ionescu M (2005) Chemistry and technology of polyols for polyurethanes. iSmithers Rapra Publishing, Shrewsbury

Yeganeh H, Hojati-Talemi P (2007) Polym Degrad Stab 92:480–484

Szycher M (1999) Szycher’s handbook of polyurethanes. CRC Press, New York

Gholami H, Yeganeh H, Burujeny SB, Sorayya M, Shams E (2017) J Polym Environ 1–12

Joseph J, Jemmis ED (2007) J Am Chem Soc 129:4620–4632

Ghandi M, Mostashari A, Karegar M, Barzegar M (2007) J Am Oil Chem Soc 84:681–685

Serkis M, Špírková M, Poręba R, Hodan J, Kredatusová J, Kubies D (2015) Polym Degrad Stab 119:23–34

Chun BC, Chong MH, Chung YC (2007) J Mater Sci 42:6524–6531

Vermette P, Griesser HJ, Laroche G, Guidoin R (2001) Biomedical applications of polyurethanes. Landes Bioscience, Georgetown

Špírková M, Hodan J, Kobera L, Kredatusová J, Kubies D, Machová L (2017) Polym Degrad Stab 137:216–228

Pan J, Li G, Chen Z, Chen X, Zhu W, Xu K (2009) Biomater 30:2975–2984

Zulkifli FH, Hussain FSJ, Rasad MSBA., Yusoff MM (2014) Carbohydr Polym 114:238–245

Cauich-Rodríguez JV, Chan-Chan LH, Hernandez-Sánchez F, Cervantes-Uc JM (2013) In: Pignatello R (ed) Advances in biomaterials science and biomedical applications. Intech, Croatia

Sarkar D, Yang JC, Lopina ST (2008) J Appl Polym Sci 108:2345–2355

Guan J, Stankus JJ, Wagner WR (2007) J Control Release 120:70–78

Chang CH, Tsao CT, Chang KY, Chen SH, Han JL, Hsieh KH (2012) Biomed Mater Eng 22:373–382

Wang L, Li Y, Zuo Y, Zhang L, Zou Q, Cheng L, Jiang H (2009) Biomed Mater 4:025003

Tanaka R, Hirose S, Hatakeyama H (2008) Bioresour Technol 99:3810–3816

Dong Z, Li Y, Zou Q (2009) Appl Surf Sci 255:6087–6091

Kowalczuk D, Ginalska G, Przekora A (2011) J Biomed Mater Res A 98A:222–228

Lönnroth EC, Dahl JE (2003) Acta Odontol Scand 61:52–56

González-Paz RJ, Ferreira AM, Mattu C, Boccafoschi F, Lligadas G, Ronda JC (2013) React Funct Polym 73:690–697

Acknowledgements

The work was supported by University Malaya Research Grant (RG250-12AFR) and Postgraduate Research Fund (PG051-12AFR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, W.S., Lee, C.S., Cheng, SF. et al. Biocompatible Polyurethane Scaffolds Prepared from Glycerol Monostearate-Derived Polyester Polyol. J Polym Environ 26, 2881–2900 (2018). https://doi.org/10.1007/s10924-017-1175-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1175-2