Abstract

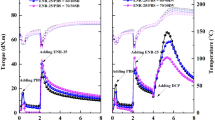

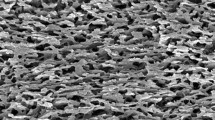

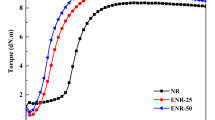

Novel biodegradable thermoplastic elastomer based on epoxidized natural rubber (ENR) and poly(butylene succinate) (PBS) blend was prepared by a simple blend technique. Influence of blend ratios of ENR and PBS on morphological, mechanical, thermal and biodegradable properties were investigated. In addition, chemical interaction between ENR and PBS molecules was evaluated by means of the rheological properties and infrared spectroscopy. Furthermore, the phase inversion behavior of ENR/PBS blend was predicted by different empirical and semi-empirical models including Utracki, Paul and Barlow, Steinmann and Gergen models. It was found that the co-continuous phase morphology was observed in the blend with ENR/PBS about 58/42 wt% which is in good agreement with the model of Steinmann. This correlates well to morphological and mechanical properties together with degree of crystallinity of PBS in the blends. In addition, the biodegradability was characterized by soil burial test after 1, 3 and 9 months and found that the biodegradable ENR/PBS blends with optimum mechanical and biodegradability were successfully prepared.

Similar content being viewed by others

References

Samia B, Farid R (2014) Dynamic mechanical and thermal properties of a chemically modified polypropylene/natural rubber thermoplastic elastomer blend. Polym Test 36:54–61

Nakason C, Wannavilai P, Kaesaman A (2006) Effect of vulcanization system on properties of thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends. Polym Test 25:34–41

Nakason C, Jarnthong M, Kaesaman A, Kiatkamjornwong S (2009) Influences of blend proportions and curing systems on dynamic, mechanical, and morphological properties of dynamically cured epoxidized natural rubber/high-density polyethylene blends. Polym Eng Sci 49:281–292

Mousa A, Ishiaku US. Mohd Ishak ZA (2000) Rheological properties of dynamically vulcanized poly(vinyl chloride)/epoxidized natural rubber thermoplastic elastomers: effect of processing variables. Polym Test 19:193–204

Ishiaku US, Shaharum A, Ismail H. Mohd Ishak ZA (1998) The effect of an epoxidized plasticizer on the thermo-oxidative ageing of poly(vinyl chloride)/epoxidized natural rubber thermoplastic elastomers. Polym Int 45:83–91

Nakason C, Narathichat M, Kummerlöwe C, Vennemann N (2012) Thermoplastic natural rubber based on polyamide-12 blended with various types of natural rubber: effect of processing oils and plasticizer. J Elastomers Plast 45:47–75

Romin R, Nakason C, Thitithammawong A (2013) Thermoplastic elastomer based on epoxidized natural rubber/polyamide-12 and co-polyamide-12 blends. Adv Mater Res 626:58–61

Mishra J, Chang YW, Kim DK (2007) Green thermoplastic elastomer based on polycaprolactone/epoxidized naturalrubber blend as a heat shrinkable material. Mater Lett 61:3551–3554

Wahit MU, Hassan A, Ibrahim AN, Zawawi NA, Kunasegeran K (2015) Mechanical, thermal and chemical resistance of epoxidized natural rubber toughened polylactic acid blends. Sains Malays 44:1615–1623

Mendes JF, Paschoalin RT, Carmona VB, Neto ARS, Marques ACP, Marconcini JM, Mattoso LHC, Medeiros ES, Oliveira JE (2016) Biodegradable polymer blends based on corn starch and thermoplastic chitosan processed by extrusion. Carbohydr Polym 137:452–458

Liu D, Qi Z, Zhang Y, Xu J, Guo B (2015) Poly(butylene succinate) (PBS)/ionic liquid plasticized starch blends: preparation, characterization, and properties. Starch-Stärke 67:802–809

Bhatia A, Gupta Rahul K, Bhattacharya Sati N, Choi HJ (2007) Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. Korea-Aust Rheol J 19:125–131

Hassan E, Wei Y, Jiao H, Muhuo Y (2013) Dynamic mechanical properties and thermal stability of poly(lactic acid) and poly(butylene succinate) blends composites. J Fiber Bioeng Inform 6:85–94

Stoyanova N, Paneva D, Mincheva R, Toncheva A, Manolova N, Dubois P, Rashkov I (2014) Poly(l-lactide) and poly(butylene succinate) immiscible blends: from electrospinning to biologically active materials. Mater Sci Eng C 41:119–126

Wang R, Wang S, Zhang Y, Wan C, Ma P (2009) Toughening modification of PLLA/PBS blends via in situ compatibilization. Polym Eng Sci 49:26–33

Yin Q, Chen F, Zhang H, Liu C (2015) Mechanical properties and thermal behavior of TPS/PBS blends with maleated PBS as a compatibilizer. Adv Mater Res 1119:306–309

Hemsri S, Thongpin C, Moradokpermpoon N, Niramon P, Suppaso M (2015) Mechanical properties and thermal stability of poly(butylene succinate)/acrylonitrile butadiene rubber blend. Macromol Symp 354:145–154

Jamaluddin N, Razaina MT, Mohd Ishak ZA (2016) Mechanical and morphology behaviours of polybutylene (succinate)/thermoplastic polyurethane blend. Proc Chem 19:426–432

Pichaiyut S, Wisunthorn S, Thongpet C, Nakason C (2016) Novel ternary blends of natural rubber/linear low‑density polyethylene/thermoplastic starch: influence of epoxide level of epoxidized natural rubber on blend properties. Iran Polym J 25:711–723

Tanrattanakul V, Bunkaew P (2014) Effect of different plasticizers on the properties of bio-based thermoplastic elastomer containing poly(lactic acid) and natural rubber. Express Polym Lett 8:387–396

Utracki LA (1991) On the viscosity-concentration dependence of immiscible polymer blends. J Rheol 35:1615–1637

Paul DR. Barlow JW (1980) Polymer blends (or Alloys). J Macromol Sci Rev Macromol Chem Phys 18:109–168

Steinmann S, Gronski W, Friedrich C (2001) Cocontinuous polymer blends: influence of viscosity and elasticity ratios of the constituent polymer on phase inversion. Polymer 42:6619–6629

Gergen WP, Lutz RG, Davison S (1996) Hydrogenated block copolymers in thermoplastic elastomer interpenetrating polymer networks. In: Holden G, Legge NR, Quirk R, Schroeder HE (eds) Thermoplastic elastomers, 2nd edn. Hanser Publisher, Munich

Mltsuyoshl F, Youtoku K (1991) Rheological properties of polypropylene/ high-density polyethylene blend melts. Ι. capillary flow properties. J Appl Polym Sci 42:467–480

Poh BT, Yong AT (2009) Dependence of peel adhesion on molecular weight of epoxidized natural rubber. J Adhes 85:435–446

Yoo E, Im SS (1999) Melting behavior of poly(butylene succinate) during heating scan by DSC. J Polym Sci Part B: Polym Phys 37:1357–1366

Gelling IR (1991) Epoxide natural rubber. J Nat Rubber Res 6:184–205

Nakason C, Jamjinno S, Kaesaman A, Kiatkamjornwong S (2008) Thermoplastic elastomer based on high-density polyethylene/natural rubber blends: rheological, thermal, and morphological properties. Polym Adv Technol 19:85–98

Favis BD, Chalifoux JP (1988) Influence of composition on the morphology of polypropylene/polycarbonate blends. Polymer 29:1761–1767

Mekhilef N, Verhoogt H (1996) Phase inversion and dual-phase continuity in polymer blends: theoretical predictions and experimental results. Polymer 37:4069–4077

Han MS, Seo WJ, Paik HS, Hyun JC, Lee JW, Kim WN (2003) Rheological properties and phase inversion of polypropylene and poly(styrene-co-acrylonitrile) blends. Polym J 35:127–132

Pongtanayut K, Thongpin C, Santawitee O (2013) The effect of rubber on morphology, thermal properties and mechanical properties of PLA/NR and PLA/ENR blends. Energy Procedia 34:888–897

Anankaphong H, Pentrakoon D, Junkasem J (2015) Effect of rubberwood content on biodegradability of poly(butylene succinate) biocomposites. Int J Polym Sci 1–9

Eng AH, Tanaka Y, Gan SN (1997) Some properties of epoxidised deproteinised natural rubber. J Nat Rubber Res 12:82–89

Fainleib A, Renata VP, Elizabete FL, Bluma GS (2013) Degradation of non-vulcanized natural rubber-renewable resource for fine chemicals used in polymer synthesis. Institute of Macromolecular Chemistry, The National Academy of Sciences of Ukraine, NASU, Kyiv

Afiq MM, Azura A (2013) Effect of sago starch loadings on soil decomposition of natural rubber latex (NRL) composite films mechanical properties. Int Biodeterior Biodegradation 85:139–149

Tserki V, Matzinos P, Pavlidou E, Vachliotis D, Panayiotou C (2006) Biodegradable aliphatic polyesters. Part I. properties and biodegradation of poly(butylene succinate-co-butylene adipate). Polym Degrad Stab 91:367–376

Llorens E, Ibañez H, Valle LJ del, Puiggalí J (2015) Biocompatibility and drug release behavior of scaffolds prepared by coaxial electrospinning of poly(butylene succinate) and polyethylene glycol. Mater Sci Eng 49:472–484

Wichian AN (2013) Preparation and mechanical property of the epoxidized natural rubber from field latex. Rubber Thai J 2:1–8

Salaeh S, Nakason C (2012) Influence of modified natural rubber and structure of carbon black on properties of natural rubber compounds. Polym Compos 33:489–500

Nakaramontri Y, Nakason C, Kummerlowe C, Vennemann N (2015) Effects of in-situ functionalization of carbon nanotubes with bis(triethoxysilylpropyl) tetrasulfide (TESPT) and 3-aminopropyltriethoxysilane (APTES) on properties of epoxidized natural rubber-carbon nanotube composites. Polym Eng Sci 55:2500–2510

Nakaramontri Y, Nakason C, Kummerlowe C, Vennemann N (2016) Enhancement of electrical conductivity and filler dispersion of carbon nanotube filled natural rubber composites by latex mixing and in situ silanization. Rubber Chem Technol 89:272–291

Gong-Peng L, Ling L, Xiu-Li W, Li C, Yu-Zhong W (2015) PBT/PC blends compatibilized and toughened via copolymers in situ formed by mgo-catalyzed transesterification. Ind Eng Chem Res 54:1282–1291

Acknowledgements

This research was financially supported by a grant from the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission, contract No. SIT580647S, by the Thailand Research Fund (TRF) through the Royal Golden Jubilee Ph.D. Program (Grant No. PHD/0208/2557) to Dr. Charoen Nakason as principal researcher, and to Miss Parisa Faibunchan as the research assistant and by Prince of Songkla University, Surat Thani Campus. The authors would like to express their gratitude to the University of Applied Science, Osnabruck, Germany, for their research facilities and the other supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faibunchan, P., Nakaramontri, Y., Chueangchayaphan, W. et al. Novel Biodegradable Thermoplastic Elastomer Based on Poly(butylene succinate) and Epoxidized Natural Rubber Simple Blends. J Polym Environ 26, 2867–2880 (2018). https://doi.org/10.1007/s10924-017-1173-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1173-4