Abstract

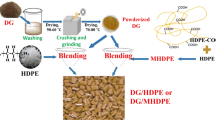

The steady increase in production of corn based ethanol fuel has dramatically increased the supply of its major co-product known as distiller’s dried grain with solubles (DDGS). Large amount of DDGS and corn flour are used as an animal feed. The elusieve process can separate DDGS or corn flour into two fractions: DDGS fraction with enhanced protein and oil content or corn flour fraction with high starch content, and hull fiber. This study investigated the feasibility of using fiber from DDGS and corn grain as alternative fillers to wood fiber in high density polyethylene (HDPE) composites made with two different sources of polymers. Two fiber loading rates of 30 and 50% were evaluated for fiber from DDGS, corn, and oak wood (control) to assess changes in various physical and mechanical properties of the composite materials. Two HDPE polymers, a bio-based HDPE made from sugarcane (Braskem), and a petroleum based HDPE (Marlex) were also compared as substrates. The biobased polymer composites with DDGS and corn fibers showed significantly lower water absorption than the Marlex composite samples. The Braskem composite with 30% DDGS fiber loading showed the highest impact resistance (80 J/m) among all the samples. The flexural properties showed no significant difference between the two HDPE composites.

Similar content being viewed by others

References

Klopfenstein TJ, Erickson GE, Berger LL (2013) Field Crop Res 153:5

Dinneen B (2014) Renew Fuels Assoc http://www.ethanolrfa.org/. Accessed 15 Aug 2016

Belyea RL, Rausch KD, Tumbleson ME (2004) Bioresour Technol 94:293

Cheesbrough V, Rosentrater KA, Visser J (2008) J Polym Environ 16:40

Rosentrater KA, Muthukumarappan K (2006) Int Sugar J 108:645

Shurson GC (2002) The value and use of distiller’s dried grains with solubles (DDGS) in swine diets. Carolina Nutrition Conference, Raleigh, NC

Srinivasan R, Moreau RA, Rausch KD, Belyea RL, Tumbleson ME, Singh V (2005) Cereal Chem 82:528

Srinivasan R, Yadav MP, Belyea RL, Rausch KD, Pruiett LE, Johnston DB, Tumbleson ME, Singh V (2008) Biol Eng 1:39

Kim E, Parsons C, Singh V (2007) Poult Sci 86:397

Loar RE, Srinivisan R, Dozier WA III, Kidd MT, Corzo A (2008) Poult Sci 87:28

Gurunathan T, Mohanty S, Nayak SK (2015) Comp Part A 77:1

Ahmad F, Choi HS, Park MK (2015) Macromol Mater Eng 300:10

Thakur VK, Thakur MK, Gupta RK (2014) Int J Polym Anal Charact 19:256

Xie Y, Hill CA, Xiao Z, Militz H, Mai C (2010) Compos Part A 41(7):806–819

Thakur VK, Thakur MK, Gupta RK (2014) Carbohydr Polym 104:87–93

Li X, Tabil LG, Panigrahi S (2007) J Polym Environ 15(1):25–33

Adekunle KF (2015) Open J Polym Chem 5(03):41

Li Y, Sun XS (2010) J Appl Polym Sci 121:589

Muniyaswamy S, Reddy MM, Misra M, Mohanty A (2013) Ind Crops Prod 43:812

Bajwa SG, Bajwa DS, Holt G, Coffelt T, Nakayama F (2011) Ind Crops Prod 33(3):747

Liang G, Xu J, Bao S, Xu W (2004) J Appl Polym Sci 91:3974

Sanadi AR, Caulfield DF, Jacobson RE, Rowell RM (1995) Ind Eng Chem Res 34:1889

Bismarck A, Askargorta IA, Springer J, Lampke T, Wielage B, Stamboulis A (2002) Polym Compos 23:872

Zabihzadeh SM (2010) Bio Resour 5:316

Tisserat B, Reifschneider L, Kuru RHO, Finkenstadt VL (2013) Bio Resour 8:59

Thwe MM, Liao K (2003) J Mater Sci Lett 38:363

Singh S, Mohanty AK (2006) Compos Sci Technol 67:1753

Sewda K, Maiti SN (2009) J Appl Polym Sci

Acknowledgements

The authors gratefully acknowledge North Dakota Corn Utilization Council for funding this research project (Grant No. FAR0021049). We would also like to acknowledge Sujal Bhattacharjee, a graduate student from NDSU for his help with sample preparations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, P., Bajwa, S. & Bajwa, D. Fiber from DDGS and Corn Grain as Alternative Fillers in Polymer Composites with High Density Polyethylene from Bio-based and Petroleum Sources. J Polym Environ 26, 2311–2322 (2018). https://doi.org/10.1007/s10924-017-1108-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1108-0