Abstract

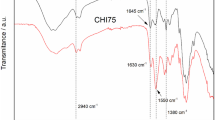

The synthesis and characterization of poly (acrylic acid) grafted pectin hydrogel followed by biosorption and desorption characteristics of cadmium, as a model heavy metal, have been studied. The grafted eco-friendly pectin based interpenetrating hydrogel was prepared in the presence of gluteraldehyde crosslinker under N2 atmosphere and characterized using 1H-NMR, FTIR, TGA and SEM techniques. Gluteraldehyde was found to form one-arm and two-arm crosslinks in the copolymer. Upon grafting, two-dimensional sheet structures bounded to tubular and vascular cylindrical rods were observed. The biosorption and desorption data, determined experimentally, were fitted to pseudo-second order reaction kinetics. At higher ionic strength values, the maximum metal uptake value (q max) was lowered and pseudo-second order rate constant (k 2) was increased. Whereas, at higher pH values the maximum metal uptake value (q max) was increased and Pseudo-second order rate constant (k 2) was decreased. 0.1 M HCl solution was a suitable eluent to regenerate the hydrogel surface and recover the adsorbed cadmium metal ions. Pectin based copolymer could be used as an efficient candidature biosorbent for the recovery of cadmium metal ions from aqueous solutions.

Similar content being viewed by others

References

Davidson MH, Dugan LL, Stocki J, Dicklin MR, Maki KC, Coletta F, Cotter R, McLeod M, Hoersten K (1998) J Nutr 128:1927

Chourasia MK, Jain SK (2004) Drug Delivery 11:129

Liu L, Fishman ML, Kost J, Hicks KB (2003) Biomaterials 24:3333

Sriamornsak P, Nunthanid J (1999) J Macroencapsul 16:303

Fares MM, Assaf SM, Abul-Haija YM (2010) J Appl Polym Sci 117(4):1945

Kartel MT, Kupchik LA, Veisov BK (1999) Chemosphere 38:2591

Khvan AM, Abduazimov KA (2001) Chem Nat Comp 37:388

Kamnev AA, Ptichkina NM, Perfiliev YD, Shkodina OG, Ignatov VV (1995) J Inorg Biochem 59:340

Harel P, Mignot L, Sauvage JP, Junter GA (1998) Ind Crop Prod 7:239

Dronnet VM, Renard CM, Axelos MA, Thibault JF (1999) Carbohydr Polym 30:253

Namasivayam C, Ranganathan K (1995) Environ Technol 16:851

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) Water Res 33:2469

Hegazy EA, Abd SE, Taleb MF, Dessouki AM (2004) J Appl Polym Sci 92:2642

Inam R, Caykara T, Kantoglu O (2003) Nuc Inst Meth Phys Res B 208:400

Inam R, Gumu Y, Caykara T (2004) J Appl Polym Sci 94:2401

Ulusoy U, Symsek S, Ceyhan O (2003) Adsorption 9:165

Rivas BL, Hernan AP, Maturana A, Villegas S (2001) Macromol Chem Phys 202:443

Saraydin D, Karadag E, Guven O (2001) J Appl Polym Sci 79:1809

Fares MM, Othman AA (2008) J Appl Polym Sci 110(5):2815

Fares MM, Othman AA (2010) J Macromol Sci Part A: Pure Appl Chem 47(1):61

Merlin DL, Sivasankar B (2009) Euro Polym J 45:165

Culin J, Smit I, Andreis M, Veksli Z, Anzlovar A, Zigon M (2005) Polymer 46:89

Zhang XZ, Wu DQ, Chu CC (2004) Biomaterials 25:3793

Langer R (2003) N A Peppas AIChE J 49:2990

Jeong B, Gutowska A (2002) Trends Biotechnol 20:305

Renard CM, Crepeau MJ, Thibault JF (1995) Carbohydrate Res 275:155

Volesky B (2003) Sorption and biosorption. BV-Sorbex,Inc., St. Lambert, Quebec

Mehta SK, Gaur JP (2005) Crit Rev Biotechnol 25:113

Fares MM, El-faqeeh AS, Osman ME (2003) J Polym Res 10(2):119

Swinkles JJM (1985) Starch conversion technology. Marcel Dekker, New York, p 30

Acknowledgments

Jordan University of Science and Technology is acknowledged for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fares, M.M., Tahboub, Y.R., Khatatbeh, S.T. et al. Eco-Friendly, Vascular Shape and Interpenetrating Poly (Acrylic Acid) Grafted Pectin Hydrogels; Biosorption and Desorption Investigations. J Polym Environ 19, 431–439 (2011). https://doi.org/10.1007/s10924-011-0296-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0296-2