Abstract

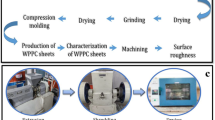

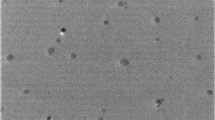

In the present work, sawdust reinforced polypropylene composites were fabricated using an extruder and an injection molding machine. Raw sawdust was chemically treated with benzene diazonium salt in order to improve the mechanical properties of the composites. The effect of the chemically treated sawdust reinforced PP composites was evaluated from their mechanical and surface morphological properties. The values of the mechanical properties of the chemically treated sawdust–PP composites were found to be significantly higher than those of the raw ones. Water uptake tests revealed that composites prepared from the chemically treated sawdust absorb lower amount of water compared to the ones prepared from raw sawdust, suggesting that hydrophilic nature of the cellulose in the sawdust has significantly decreased upon chemical treatment. The surface morphology obtained from scanning electron microscopy (SEM) showed that raw sawdust–PP composites possess surface roughness with extruded filler moieties, and weak interfacial adhesion between the matrix and the filler while the chemically treated one showed improved filler–matrix interaction. This indicates that better dispersion of the filler with the PP matrix has occurred upon chemical treatment of the filler.

Similar content being viewed by others

References

Sanadi AR, Caulfield DF, Jacobson RE, Rowell RM (1995) Ind Eng Chem Res 34:1889

Mohanty AK, Misra M, Drazil LT (2002) J Polym Environ 10:19

Dipa R, Sengupta PS, Rana AK, Bose NR (2006) Ind Eng Chem Res 45:2722

Kuan CK, Kuan HC, Ma CCM, Huang CC (2006) Composites A 37:1696

Karmakar A, Chauhan SS, Modak JM, Chanda M (2007) Composites A 38:227

Matuana LM, Park CB, Balatinecz JJ (1998) Polym Eng Sci 38(11):1862–1872

Maldas D, Kokta VV (1993) Role of coupling agents and treatment on the performance of wood fiber–thermoplastic composites, fundamental concepts, processes and material opinions. Forest Product Society, Madison, USA, p 112

Rowell RM, Tillman AM, Simonson RA (1986) J Wood Chem Technol 6:427

Rana AK, Mitra BC, Banerjee AN (1999) J Appl Polym Sci 71:531

Raj RG, Kokta BV, Dembele F, Sanschagrain B (1989) J Appl Polym Sci 38:1987

Jamil SJ, Ahmed I, Ibrahim A (2006) J Polym Res 13:315

Bledzki AK, Gassan J (1999) Prog Polym Sci 24:221

Qui W, Mai K, Zeng H (2000) J Appl Polym Sci 77:2974

Ismail H, Edyhan MR, Wirjosentono B (2002) Polym Test 21:139

Rahman MR, Huque MM, Islam MN, Hasan M (2009) Composites A 40:511

Rahman MR, Huque MM, Islam MN, Hasan M (2008) Composites A 39:1739

Rahman MR, Huque MM, Hasan M, Islam MN (2010) J Reinf Plast Compos 29:445

ASTM Standard D 638-01 (2002) Standard test methods for tensile properties of plastics. Annual book of ASTM Standard, vol 08.03.2002

ASTM Standard D 790-00 (2002) Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. Annual book of ASTM Standard, vol 08.01.2002

ASTM Standard D 6110-97 (2002) Standard test methods for determining the Charpy impact resistance of notched specimens of plastics. Annual book of ASTM Standard, vol 08.03.2002

ASTM Standard D 785-98 (2002) Standard test method for Rockwell hardness of plastics and electrical insulating materials. Annual book of ASTM Standard, vol 08.01.2002

ASTM Standard D 570-99 (2002) Standard test methods for water absorption of plastics. Annual book of ASTM Standard, vol 08.01.2002

Lou CW, Lin CW, Lei CH, Su KH, Hsu CH, Liu ZH, Lin JH (2007) J Mater Process Technol 192/193:428

Lee SY, Yang HS, Kim H-J, Jeong CS, Lim BS, Lim Lee JN (2004) Compos Struct 65:459

Segal L, Wakelyn PJ (1985) Cotton fiber. In: Handbook of fiber science and technology, fiber chemistry, vol 4. Marcel Dekker Inc., New York, p 868

Joseph S, Sreekala MS, Oommen Z, Koshy P, Thomas SA (2002) Compos Sci Technol 62:1857

Joseph PV, Mathew G, Joseph K, Groeninckx G, Thomas SA (2003) Composites A 34:275

Hristov VN, Lach R, Grellmann W (2004) Polym Test 23:581

Lin JC, Chang LC, Nien MH, Ho HL (2006) Compos Struct 74:30

Mishra S, Naik JB, Patil YP (2000) Compos Sci Technol 60:1729

Premlal HGB, Ismail H, Baharin A (2002) Polym Test 21:833

Yang HS, Kim HJ, Park HJ, Lee BJ, Hwang T-S (2006) Compos Struct 72:429

Yang HS, Kim HJ, Park HJ, Lee BJ, Hwang T-S (2007) Compos Struct 77:45

Choi NW, Mori I, Ohama Y (2006) Waste Manag 26:189

Matuana LM, Balatinecz JJ, Sodhi RNS, Park CB (2001) Wood Sci Technol 35:191

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezaur Rahman, M., Nazrul Islam, M. & Monimul Huque, M. Influence of Fiber Treatment on the Mechanical and Morphological Properties of Sawdust Reinforced Polypropylene Composites. J Polym Environ 18, 443–450 (2010). https://doi.org/10.1007/s10924-010-0230-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-010-0230-z