Abstract

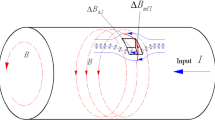

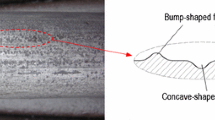

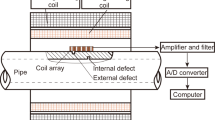

This paper analyzes the inspection characteristics of the alternating current electric flux leakage (AC-EFL) testing method. Three specimens with different conductivity are prepared, and a series of experiments is carried out to explore the advantages and disadvantages of the AC-EFL method. For metal materials that carry an alternating current (AC), defect detection can be realized using both AC-EFL and electric current perturbation (ECP). However, the signal noise ratio (SNR) from using the AC-EFL method is lower than that obtained using the ECP method according to the experimental results obtained from an aluminum plate. For both the Ni–Zn ferrite specimens with very low conductivity and the carbon fiber reinforced polymer (CFRP) specimens with low anisotropic conductivity, the ECP method failed to detect defects because of the weak disturbed magnetic field that was caused by the defects, whereas the AC-EFL method was able to realize the defect detection. These proof-of-concept experimental results indicate that compared to magnetic field testing method, the AC-EFL is more suitable for inspecting low-conductivity materials.

Similar content being viewed by others

References

Hernandes, J.A., Assis, A.K.T.: Electric potential for a resistive toroidal conductor carrying a steady azimuthal current. Phys. Rev. E 68(4), 046611 (2003)

Hernandes, J.A., Assis, A.K.T.: Surface charges and external electric field in a toroid carrying a steady current. Braz. J. Phys. 34, 1738–44 (2004)

Hernandes, J.A., Assis, A.K.T.: Electric potential due to an infinite conducting cylinder with internal or external point charge. J. Electrostat. 63, 1115–31 (2005)

Hernandes, J.A., Mania, A.J., Luna, F.R.T., et al.: The internal and external electric fields for a resistive toroidal conductor carrying a steady poloidal current. Phys. Scripta 78(1), 015403 (2008)

Ye, Z., Sun, Y., Kang, Y., et al.: An alternating current electric flux leakage testing methodology and experimental research for metallic materials. NDT E Int. 67, 36–45 (2014)

Ye, Z., Kang, Y., Sun, Y., Yang, G., Feng, B., Zhou, Q.: Theoretical analyses of an alternating current electric flux leakage inspection method and experimental verification. Insight-Non-Destruct. Test. Cond. Monit. 57, 78–84 (2015)

Beissner, R., Sablik, M.: Theory of Electric Current Perturbation Probe Optimization, Review of Progress in Quantitative Nondestructive Evaluation, pp. 633–641. Springer, New York (1984)

Beissner, R., Teller, C., Burkhardt, G., Smith, R., Barton, J.: Detection and Analysis of Electric-Current Perturbation Caused by Defects. Eddy-Current Characterization of Materials and Structures, pp. 428–446. ASTM International, West Conshohocken (1981)

Burkhardt, G.L., Beissne, R.E.: Electric Current Perturbation NDE, pp. 136–42. ASM Handbook Committee, Materials Park (1989)

Bowler, N.: Electric field due to alternating current injected at the surface of a metal plate. J Appl. Phys. 96, 4607–13 (2004)

Bowler, N.: Analytical solution for the electric field in a half space conductor due to alternating current injected at the surface. J Appl. Phys. 95, 344–8 (2004)

Schulze, M.H., Heuer, H., Küttner, M., Meyendorf, N.: High-resolution eddy current sensor system for quality assessment of carbon fiber materials. Microsyst. Technol. 16, 791–7 (2010)

Mook, G., Lange, R., Koeser, O.: Non-destructive characterisation of carbon-fibre-reinforced plastics by means of eddy-currents. Compos. Sci. Technol. 61, 865–73 (2001)

Cheng, J., Ji, H., Qiu, J., Takagi, T., Uchimoto, T., Hu, N.: Novel electromagnetic modeling approach of carbon fiber-reinforced polymer laminate for calculation of eddy currents and eddy current testing signals. J. Compos. Mater. 49(5), 617–631 (2014)

Yin, W., Li, X., Withers, P., Peyton, A.: Non-contact characterization of hybrid aluminium/carbon-fibre-reinforced plastic sheets using multi-frequency eddy-current sensors. Meas. Sci. Technol. 21, 105708 (2010)

Koyama, K., Hoshikawa, H., Kojima, G.: Eddy current nondestructive testing for carbon fiber-reinforced composites. J. Press. Vessel Technol. 135, 041501 (2013)

Acknowledgements

This paper was financially supported by the National Natural Science Foundation of China (51475194), the National Key Basic Research Program of China (2014CB046706) and the Fundamental Research Funds for the Central Universities (Grant No. 2015MS015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Liu, S., Ye, Z. et al. Alternating Current Electric Flux Leakage Testing for Defect Detection and Characterization. J Nondestruct Eval 37, 15 (2018). https://doi.org/10.1007/s10921-018-0469-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0469-1