Abstract

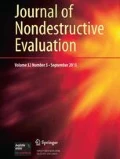

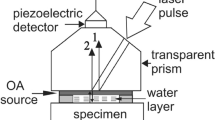

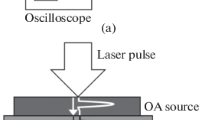

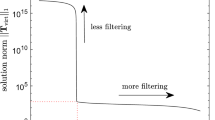

The laser-ultrasonic method for nondestructive quantitative local porosity assessment for CFRP composites is proposed and realized experimentally for only one available flat surface of a specimen or a product. This method combines the laser thermoelastic generation and the high-sensitivity piezoelectric detection of broadband pulses of longitudinal ultrasonic waves and does not require the detection of the backwall echo ultrasonic signal. The generation and the detection of ultrasonic pulses is carried out with the specially designed laser-ultrasonic transducer, which allows one to obtain both the temporal profile and the frequency spectrum of a part of the ultrasonic signal backscattered by gas voids in a composite specimen. The frequency spectrum of backscattered ultrasonic pulses is analyzed for three sets of CFRP specimens with different epoxy matrix fractions and porosity. The empirical relation between porosity of CFRP specimens and the spectral power (structural noise power) of ultrasonic signals backscattered by voids is obtained for porosity values up to 0.15. This relation allows one to evaluate the local porosity from measured structural noise power both for CFRP specimens and products fabricated from the same composite material. The proposed laser-ultrasonic setup demonstrates a basis for a system of CFRP porosity assessment in field conditions. It can be very useful especially for nondestructive detection of structural changes of composite materials that will allow evaluation of products during their life time.

Similar content being viewed by others

References

Kelly, A., Zweben, C. (eds.): Comprehensive Composite Materials. Elsevier, Amsterdam (2000)

Adams, R.D., Cawley, P.: A review of defect types and nondestructive testing techniques for composites and bonded joints. NDT Int. 21, 208–222 (1988)

Achenbach, J.D. (ed.): Evaluation of Materials and Structures by Quantitative Ultrasonics. Springer, Wien and New York (1993)

Achenbach, J.D.: Quantitative nondestructive evaluation. Int. J. Solids Struct. 37, 13–27 (2000)

Rokhlin, S.I., Chimenti, D.E., Nagy, P.B.: Physical Ultrasonics of Composites. Oxford University Press, Oxford (2011)

Stone, D.E.W., Clarke, B.: Ultrasonic attenuation as a measure of void content in carbon-fibre reinforced plastics. Nondestruct. Test. 8, 137–145 (1975)

Martin, B.G.: Ultrasonic wave propagation in fiber-reinforced solids containing voids. J. Appl. Phys. 48, 3368–3373 (1977)

Reynolds, W.N., Wilkinson, S.J.: The analysis of fibre-reinforced porous composite materials by the measurement of ultrasonic wave velocities. Ultrasonics 16, 159–163 (1978)

Hale, J.M., Ashton, J.N.: Ultrasonic attenuation in voided fibre-reinforced plastics. NDT Int. 21, 321–326 (1988)

Daniel, I.M., Wooh, S.C., Komsky, I.: Quantitative porosity characterization of composite materials by means of ultrasonic attenuation measurements. J. Nondestruct. Eval. 11, 1–8 (1992)

Jeong, H., Hsu, D.K.: Experimental analysis of porosity-induced ultrasonic attenuation and velocity change in carbon composites. Ultrasonics 33, 195–203 (1995)

Takatsubo, J., Urabe, K., Tsuda, H., Toyama, N., Wang, B.: Experimental and theoretical investigation of ultrasound propagation in materials containing void inclusions. In: Thompson, D.O., Chimenti, D.E. (eds.) Quantitative Nondestructive Evaluation. AIP Conference Proceedings, vol. 700, pp. 1083–1090. American Institute of Physics, New York (2004)

Stone, M.A.: Evaluation of oven-cured, solid carbon/epoxy composites with various porosity levels. In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation, vol. 28. AIP Conference Proceedings, vol. 1096, pp. 1025–1032. American Institute of Physics, New York (2009)

Lin, L., Chen, J., Zhang, X., Li, X.: A novel 2-D random void model and its application in ultrasonically determined void content for composite materials. NDT E Int. 44, 254–260 (2011)

Tittmann, B.R., Ahlberg, L.A., Fertig, K.W.: Ultrasonic characterization of microstructure in powder metal alloy. In: Analytical Ultrasonics in Materials Research and Testing. NASA Conf. Publ., vol. 2383, pp. 31–49 (1984)

Tittmann, B.R., Ahlberg, L.A., Fertig, K.W.: Ultrasonic microstructural noise parameters in a powder metal alloy. In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation, vol. 3A, pp. 57–63. Plenum, New York (1984)

Kogan, V.G., Hsu, D.K., Rose, J.H.: Characterization of flaws using the zeroes of the real and imaginary parts of the ultrasonic scattering amplitude. J. Nondestruct. Eval. 5, 57–68 (1985)

Vary, A.: Material property characterization. In: Moore, P.O. (ed.) Nondestructive Testing Handbook, Ultrasonic Testing, 3rd edn. vol. 7, pp. 365–431. ASTM, Columbus (2007)

Truell, R., Elbaum, C., Chick, B.: Ultrasonic Methods in Solid State Physics. Academic Press, New York (1969)

Desilets, C.S., Fraser, J.D., Kino, G.S.: The design of efficient broad-band piezoelectric transducers. IEEE Trans. Sonics Ultrason. 25, 115–125 (1978)

Foster, F.S., Ryan, L.K., Turnbull, D.H.: Characterization of lead zirconate titanate ceramics for use in miniature high-frequency (20–80 MHz) transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 38, 446–453 (1991)

Chung, C.-H., Lee, Y.-C.: Broadband poly(vinylidene fluoride-trifluoroethylene) ultrasound focusing transducers for determining elastic constants of coating materials. J. Nondestruct. Eval. 28, 101–110 (2009)

Scruby, C.B., Drain, L.E.: Laser Ultrasonics: Techniques and Applications. Adam Hilger, Bristol (1990)

Gusev, V.E., Karabutov, A.A.: Laser Optoacoustics. American Institute of Physics, New York (1993)

Karabutov, A.A., Matrosov, M.P., Podymova, N.B., Pyzh, V.A.: Acoustic pulse spectroscopy using a laser sound source. Sov. Phys. Acoust. 37, 157–163 (1991)

Karabutov, A.A., Podymova, N.B.: Nondestructive evaluation of fatigue changes of composite structure by laser ultrasonic method. Mech. Compos. Mater. 31, 198–203 (1995)

Tittmann, B.R., Linebarger, R.S., Addison, R.C. Jr.: Laser-based ultrasonics on Gr/epoxy composite. J. Nondestruct. Eval. 9, 229–238 (1990)

Monchalin, J.-P., Neron, C.: Inspection of composite materials by laser–ultrasonics. Can. Aeronaut. Space J. 43, 23–30 (1997)

Monchalin, J.-P.: Laser—ultrasonics: from the laboratory to industry. In: Thompson, D.O., Chimenti, D.E. (eds.) Quantitative Nondestructive Evaluation. AIP Conference Proceedings, vol. 700, pp. 3–31. American Institute of Physics, New York (2004)

Sakamoto, J.M.S., Baba, A., Tittmann, B.R., Mulry, B.R., Kropf, M., Pacheco, G.M.: Nondestructive inspection of a composite material sample using laser ultrasonic system with beam homogenizer. In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation, vol. 30(B). AIP Conference Proceedings, vol. 1335, pp. 935–941. American Institute of Physics, New York (2004)

Karabutov, A.A., Savateeva, E.V., Podymova, N.B., Oraevsky, A.A.: Backward mode detection of laser-induced wide-band ultrasonic transients with optoacoustic transducer. J. Appl. Phys. 87, 2003–2014 (2000)

Karabutov, A.A., Savateeva, E.V., Zharinov, A.N., Karabutov, A.A. Jr.: Contact laser ultrasonic evaluation of construction materials. In: Proceed NDT in Progress 2009, Prague, Czech Republic, E-J. NDT, vol. 15, No. 04 (2010). http://www.ndt.net/article/Prague2009/ndtip/proceedings/Karabutov.pdf

De Moura, E.P., Normando, P.G., Gonçalves, L.L., Kruger, S.E.: Characterization of cast iron microstructure through fluctuation and fractal analyses of ultrasonic backscattered signals combined with classification techniques. J. Nondestruct. Eval. 31, 90–98 (2012)

Kechter, G.E., Achenbach, J.D.: Void characterization using ultrasonic backscatter from void clusters. Res. Nondestruct. Eval. 1, 13–29 (1989)

Scott, W.R., Gordon, P.F.: Ultrasonic spectral analysis for nondestructive testing of layered composite materials. J. Acoust. Soc. Am. 62, 108–116 (1984)

Dean, E.A.: Elastic moduli of porous sintered materials as modeled by a variable–aspect–ratio self-consistent oblate-spheroidal-inclusion theory. J. Am. Ceram. Soc. 66, 847–854 (1983)

Maitra, A.K., Phani, K.K.: Ultrasonic evaluation of elastic parameters of sintered powder compacts. J. Mater. Sci. 29, 4415–4419 (1994)

Phani, K.K.: Porosity dependence of ultrasonic velocity in sintered materials—a model based on the self-consistent spheroidal inclusion theory. J. Mater. Sci. 31, 272–279 (1996)

Polyakov, V.V., Golovin, A.V.: The effect of porosity on the velocity of ultrasonic waves in metals. Tech. Phys. Lett. 20, 452–453 (1994)

Polyakov, V.V., Golovin, A.V.: Elastic moduli of porous metals. Phys. Met. Metallogr. 79, 147–149 (1995)

Sayers, C.M., Smith, R.L.: The propagation of ultrasound in porous media. Ultrasonics 20, 201–205 (1982)

Boccaccini, D.N., Boccaccini, A.R.: Dependence of ultrasonic velocity on porosity and pore shape in sintered materials. J. Nondestruct. Eval. 16, 187–192 (1997)

Lin, L., Luo, M., Tian, H.T.: Experimental investigation on porosity of carbon fiber-reinforced composite using ultrasonic attenuation coefficient. In: Proceed WCNDT 2008, Shanghai, China, vol. 3, pp. 2249–2257. Curran Associates, Inc., New York (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karabutov, A.A., Podymova, N.B. Nondestructive Porosity Assessment of CFRP Composites with Spectral Analysis of Backscattered Laser-Induced Ultrasonic Pulses. J Nondestruct Eval 32, 315–324 (2013). https://doi.org/10.1007/s10921-013-0184-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-013-0184-x