Abstract

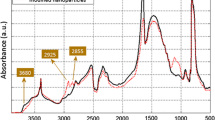

Boron nitride nanoparticles were prepared in a muffle furnace at 1000 °C by using commercial available boron nitride flakes and sodium chloride as raw materials. The structure, functional groups, morphology and specific surface area of the as-prepared samples were characterized by X-ray diffracmeter, fourier-transform infrared spectrometer, transmission electron microscope and accelerated surface area/porosimetry system, respectively. In order to evaluate the properties of the as-prepared products, they were mixed with epoxy resin to fabricate polymer-based composites. Experimental results showed that the average size and specific surface area of the as-prepared nanoparticles were about 20 nm and 895.7 m2/g. Moreover, the as-prepared nanoparticles could improve the tensile strength and elongation at break of the epoxy matrix. Both of them were first increased and then decreased with increasing the usage amount of the as-prepared nanoparticles. When the usage amount of the boron nitride nanoparticles was 0.4 wt%, the tensile strength and elongation at break of the composites reached to 71.4 MPa and 22.1%, which were the maximum values of the composites, respectivley. They were increased by 137 and 146% more than those of pure epoxy resin. In addition, the as-prepared fillers could accelerate the solidification of the matrix.

Similar content being viewed by others

References

A. Yu, P. Ramesh, X. Sun, E. Bekyarova, M. Itkis, R. Haddon, Adv. Mater. 20, 4740 (2008)

F. Ren, G. Zhu, P. Ren, Y. Wang, X. Cui, Appl. Surf. Sci. 316, 549 (2014)

J. Liang, Y. Wang, Y. Huang, Y. Ma, Z. Liu, Carbon 47, 922 (2009)

J.C. Meyer, A.K. Geim, M.I. Katsnelson, K.S. Novoselov, T.J. Booth, S.T. Roth, Nature 446, 60 (2007)

K. Manna, C.Y. Hsieh, S.C. Lo, Y.S. Li, H.N. Huang, H.W. Chiang, Carbon 105, 551 (2016)

Y. Xue, X. Jin, Y. Fan, R. Tian, X. Xu, Polym. Compos. 3, 1707 (2014)

H.S. Matte, A. Gomathi, A.K. Manna, D.J. Late, R. Datta, S.K. Pati, Angew. Chem. 49, 4059 (2010)

R. Khan, R. Alderliesten, L. Yao, R. Benedictus, Compos. Part. A 67, 201 (2014)

W. Zhou, J. Zuo, X. Zhang, A. Zhou, J. Compos. Mater. 48, 25 (2013)

F. Huang, J.K. Jian, R. Wu, J. Mater. Sci. 51, 1 (2016)

A. Pakdel, Y. Bando, D. Golberg, Chem. Soc. Rev. 43, 934 (2014)

L. Song, L. Ci, H. Lu, P. B. Sorokin, C. H. Jin, J. Ni, A. G. Kvashnin, D. G. Kvashnin, J. Lou, B. I. Yakobson, Nano. Lett. 10, 3209 (2010)

W. Zhu, X. Gao, Q. Li, H. Li, Y. Chao, M. Li, S.M. Mahurin, H. Li, H.Y. Zhu, S. Dai, Angew. Chem. 55, 10924 (2016)

L. X. Lin, Y. Zheng, Z. H. Li, K. M. Wei, Scripta. Mater. 59, 1151 (2008)

L. Xue, B. Lu, Z.S. Wu, C. Ge, P. Wang, R. Zhang, Chem. Eng. J. 243, 494 (2014)

Y. Lin, J.W. Connell, Nanoscale 4, 6908 (2012)

J. Yu, X. Huang, C. Wu, X. Wu, G. Wang, P. Jiang, Polymer 53, 471 (2012)

R. Meier, I. Kahraman, A.T. Seyhan, S. Zaremba, K. Drechsler, Compos. Sci. Technol. 128, 94 (2016)

L. Fang, C. Wu, R. Qian, L. Xie, K. Yang, P. Jiang, RSC. Adv. 4, 679 (2014)

A. Yu, W. Xing, W. Guo, S. Qiu, X. Wang, S. Lo, Y. Hu, J. Mater. Chem. A 4, 7330 (2016)

X. Zeng, Y. Yao, Z. Gong, F. Wang, R. Song, J. Xu, C. Wong, Small 11, 6205 (2015)

M. Donnay, S. Tzavalas, E. Logakis, Compos. Sci. Technol. 110, 152 (2015)

M.B. Jakubinek, J.F. Niven, M.B. Johnson, B. Ashrafi, K.S. Kim, B. Simard, M.A. White, Phys. Status Solidi A 213, 2237 (2016)

D. Lee, S.H. Song, J.H. wang, S.H. Jin, K.H. Park, B.H. Kim, S.H. Hong, S. Jeon, Small 9, 2602 (2013)

J. Gu, Q. Zhang, J. Dang, C. Xie, Adv. Technol. 23, 1025 (2012)

L. Huang, P. Zhu, G. Li, F. Zhou, D. Lu, R. Sun, C. Wong, J. Mater. Sci. 26, 3564 (2015)

R. Siburian, J. Nakamura, J. Phys. Chem. C 116, 22947 (2012)

C. Fan, J. Feng, J. Liu, T. Gao, Z. Ye, M. Chen, X. Lv, Ceram. Int. 42, 7155 (2016)

T. Sainsbury, A. Satti, P. May, Z. Wang, I. McGovern, Y.K. Gunko, J. Coleman, J. Am. Chem. Soc. 134, 60 (2012)

L. Cao, S. Emami, K. Lafdi, Mater. Express 4, 165 (2014)

Y. Lin, T.V. Williams, J.W. Connell, J. Phys. Chem. Lett. 1, 277 (2010)

L.M. Yang, Y.J. Wang, Y.W. Sun, G.S. Luo, Y.Y. Dai, J. Colloid. Interf. Sci. 299, 823 (2006)

X.L. Ji, Q.Y. Hu, J.E. Hampsey, X.P. Qiu, L.X. Gao, J.B. He, Y, F. Lu, Chem. Mater. 18, 2265 (2006)

S.P. Singh, J. Colloid. Interf. Sci. 325, 207 (2008)

L.M. Yang, Y.J. Wang, G.S. Luo, Y.Y. Dai, Micropor. Mesopor. Mat. 84, 275 (2005)

M. A. Vargas, H. Vázquez, G. Guthausen, Thermochim. Acta. 611, 10 (2015)

J. Wan, Z. Y. Bu, C. J. Xu, H. Fan, B. G. Li, Thermochim. Acta. 525, 31 (2011)

Acknowledgements

This work was supported by Youth Science and Technology Foundation of Higher Education Institutions of Hebei Province, China (Grant No. Q2012111) and Natural Science Foundation of Hebei Province, China (Grant No. E2013210011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Xf., Zhao, Zh., Sun, Y. et al. Boron Nitride Nanoparticles with High Specific Surface Area: Preparation by a Calcination Method and Application in Epoxy Resin. J Inorg Organomet Polym 27, 1142–1147 (2017). https://doi.org/10.1007/s10904-017-0540-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-017-0540-x