Abstract

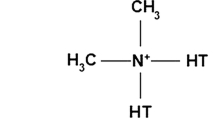

Organoclay of the type Cloisite® 20A (C-20A) with two structurally different but semicrystalline polymer matrices was studied. Polycaprolactone (PCL), a linear, biodegradable polymer, and ethylene vinyl acetate (EVA), a branched copolymer, were chosen to prepare polymer clay nanocomposites via the melt-blending method. The results show that the structure of a polymer matrix plays a significant role towards compatibilization with the silicate layers of the clay. Scanning electron microscopy and X-ray diffraction analyses revealed an exfoliated-intercalated mixed morphology for the PCL matrix. However, for the EVA matrix, silicate layers agglomerated to form tactoids and resulted primarily in an intercalated morphology. Fourier transform infrared spectroscopy was used to determine the nature of the interactions between the polymer and the filler. The thermal properties were investigated using thermogravimetric analysis and indicated that, with an increase in clay loading, the thermal stability was reduced for both matrices. Tensile tests suggested that Young’s modulus improved for the EVA matrix with an increase in clay dosage whereas for PCL the modulus was found to be highest for 8% clay loading.

Similar content being viewed by others

References

J.L. Lee, C. Zeng, X. Cia, X. Han, J. Shen, G. Xu, Compos. Sci. Technol. 65, 2344–2363 (2005)

J. Fan-Long, R. Kyong-Yop, P. Soo-Jin, Mater. Sci. Eng. Part A 429–433, 435–436 (2006)

C. Dai, P. Li, J. Yeh, Eur. Polym. J. 44, 2439–2447 (2008)

J. Yeh, T. Kuo, H. Huang, K. Chang, M. Chang, J. Yang, Eur. Polym. J. 43, 1624–1634 (2007)

A. Ladhari, H.B. Daly, H. Belhadjsalah, K.C. Cole, J. Denault, Polym. Degrad. Stab. 95, 1–11 (2010)

R.M.G. Rajapakse, K. Kurakami, H.M.N. Bandara, R.M.M.Y. Rajapakse, K. Velauthamurti, S. Wijeratne, Electrochim. Acta 55(7), 2490–2497 (2010)

M. Lai, K. Chang, J. Yeh, S. Liou, M. Hsieh, H. Chang, Eur. Polym. J. 43, 4219–4228 (2007)

B. Alexandre, D. Langevin, P. Mederic, T. Aubry, H. Counderc, Q.T. Nguyen, A. Saiter, S. Marais, J. Memb. Sci. 328, 186–204 (2009)

A. Rehab, N. Salahuddin, Mater. Sci. Eng. Part A 399, 368–376 (2005)

Y. Ke-ke, W. Xiu-Li, W. Yu-Zhong, J. Ind. Eng. Chem. 13(4), 485–500 (2007)

J.K. Pandey, K.R. Reddy, A.P. Kumar, R.P. Singh, Polym. Degrad. Stab. 88, 234–250 (2005)

K.A. Moly, H.J. Radusch, R. Androsh, S.S. Bhagawan, S. Thomas, Eur. Polym. J. 41, 1410–1419 (2005)

D.S. Chaudhary, R. Prasad, R.K. Gupta, S.N. Bhattacharya, Thermochim. Acta 433, 187–195 (2005)

W. Yaming, M.A. Rodriguez-Perez, L.R. Rui, F.M. Joa˜o, Macromol. Mater. Eng. 290, 792–801 (2005)

S.R. Chowdhury, J.K. Mishra, C.K. Das, Polym. Degrad. Stab. 70, 199–204 (2000)

A.S. Marcos, Polym. Degrad. Stab. 92, 986–996 (2007)

X. Zheng, C.A. Wilkie, Polym. Degrad. Stab. 81, 539–550 (2003)

P. Kiliaris, C.D. Papaspyrides, Prog. Polym. Sci. 35, 902–958 (2010)

S.W. Benson, P.S. Nogia, Acc. Chem. Res. 12, 228–233 (1979)

R.B. Ahmad, K. Mehrdad, H.N.F. Mohammad, H.B. Mohammad, J Hazard. Mater. 150, 136–145 (2008)

T.R. Hull, D. Price, Y. Liu, C.L. Wills, J. Brady, Polym. Degrad. Stab. 82, 365–371 (2003)

W. Tongfei, X. Tingxiu, Y. Guisheng, Appl. Clay Sci. 45, 105–110 (2009)

S. Bourbigot, J.W. Gilman, C.A. Wilkie, Polym. Degrad. Stab. 84, 483–492 (2004)

Acknowledgments

The National Research Foundation (NRF), University of Johannesburg (UJ) and the DST/Mintek Nanotechnology Innovation Centre (NIC) are gratefully acknowledged for funding this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dlamini, D.S., Mishra, S.B., Mishra, A.K. et al. Ethylene Vinyl Acetate and Polycaprolactone–Organoclay Nanocomposite: Thermal, Mechanical and Morphological Properties. J Inorg Organomet Polym 21, 229–236 (2011). https://doi.org/10.1007/s10904-011-9460-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-011-9460-3