Abstract

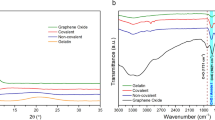

Chitin/graphene oxide (Ch/GO) composite sponges had been synthesized in 11 wt% NaOH/4 wt% urea aqueous solution by a simple method. The structure, thermal stability and mechanical properties of the composite sponges were investigated by scanning electron microscopy, Fourier-transform infrared spectroscopy, wide-angle X-ray diffraction, thermogravimetric analysis, and compressive strength measurements. The results revealed that chitin and GO were mixed homogeneously. Interestingly, the composite sponges showed meso-macroporous structure, which played an important role in improving their adsorption properties. Besides, thermal stability and mechanical properties were significantly improved compared with pure chitin sponges. Taking advantages of these fantastic characteristics, the maximum adsorption capacity of composite sponges for bilirubin was up to 422.9 mg/g under the optimized condition, which was not only significantly higher than the adsorption capacities of pure chitin sponges, but also superior to those of many reported adsorbents for removal of bilirubin. Furthermore, blood compatibility evaluations confirmed that this blended sponges had negligible hemolysis and coagulation. Therefore, this work provided a potential possibility to offer Ch/GO composite sponges for removal of bilirubin.

Similar content being viewed by others

References

Kocakulak M, Denizli A, Rad AY, Pişkin E. New sorbent for bilirubin removal from human plasma: Cibacron Blue F3GA-immobilized poly(EGDMA–HEMA) microbeads. J Chromatogr B Biomed Sci Appl. 1997;693:271–6.

Berk PD. A computer simulation study relating to the treatment of fulminant hepatic failure by hemoperfusion. Exp Biol Med. 1977;155:535–9.

Wei H, Han L, Tang Y, Ren J, Zhao Z, Jia L. Highly flexible heparin-modified chitosan/graphene oxide hybrid hydrogel as a super bilirubin adsorbent with excellent hemocompatibility. J Mater Chem B. 2015;3:1646–54.

Xu CX, Tang XJ, Niu Z, Li ZM. Studies of adsorbents for hemoperfusion in artificial liver support. I. Preparation and in vitro studies of cross-linked agarose beads entrapped activated charcoal (CAAC). Int J Artif Organs. 1981;4:200–4.

Chen Y, Tang X, Xu C, Li Z. Preparation and performance of cross-linked agar encapsulated activated charcoal (CAAC-III). J Microencapsul. 1991;8:327–34.

Ando K, Shinke K, Yamada S, Koyama T, Takai T, Nakaji S, et al. Fabrication of carbon nanotube sheets and their bilirubin adsorption capacity. Colloids Surf B Biointerfaces. 2009;71:255–9.

Wei H, Xu L, Ren J, Jia L. Adsorption of bilirubin to magnetic multi-walled carbon nanotubes as a potential application in bound solute dialysis. Colloids Surf A Physicochem Eng Asp. 2012;405:38–44.

Geiger H, Klepper J, Lux P, Heidland A. Biochemical assessment and clinical evaluation of a bilirubin adsorbent column (BR-350) in critically ill patients with intractable jaundice. Int J Artif Organs. 1992;15:35–9.

Weber V, Linsberger I, Hauner M, Leistner A, Leistner A, Falkenhagen D. Neutral styrene divinylbenzene copolymers for adsorption of toxins in liver failure. Biomacromolecules. 2008;9:1322–8.

Wu L, Zhang Z. Preparation of polyamidoamine dendrons supported on chitosan microspheres and the adsorption of bilirubin. J Appl Polym Sci. 2013;130:563–71.

Ifuku S, Morooka S, Morimoto M, Saimoto H. Acetylation of chitin nanofibers and their transparent nanocomposite films. Biomacromolecules. 2010;11:1326–30.

Chang C, Chen S, Zhang L. Novel hydrogels prepared via direct dissolution of chitin at low temperature: structure and biocompatibility. J Mater Chem. 2011;21:3865–71.

Tang H, Zhou W, Zhang L. Adsorption isotherms and kinetics studies of malachite green on chitin hydrogels. J Hazard Mater. 2012;209–210:218–25.

Duan B, Gao H, He M, Zhang L. Hydrophobic modification on surface of chitin sponges for highly effective separation of oil. ACS Appl Mater Interfaces. 2014;6:19933–42.

Ding B, Cai J, Huang J, Zhang L, Chen Y, Shi X, et al. Facile preparation of robust and biocompatible chitin aerogels. J Mater Chem. 2012;22:5801–9.

Tamura H, Nagahama H, Tokura S. Preparation of chitin hydrogel under mild conditions. Cellulose. 2006;13:357–64.

Terbojevich M, Carraro C, Cosani A, Marsano E. Solution studies of the chitin-lithium chloride- N,N -di-methylacetamide system. Carbohydr Res. 1988;180:73–86.

Ding F, Shi X, Li X, Cai J, Duan B, Du Y. Homogeneous synthesis and characterization of quaternized chitin in NaOH/urea aqueous solution. Carbohydr Polym. 2012;87:422–6.

Hu X, Du Y, Tang Y, Wang Q, Feng T, Yang J, et al. Solubility and property of chitin in NaOH/urea aqueous solution. Carbohydr Polym. 2007;70:451–8.

Liu T, Qian L, Li B, Li J, Zhu K, Deng H, et al. Homogeneous synthesis of chitin-based acrylate superabsorbents in NaOH/urea solution. Carbohydr Polym. 2013;94:261–71.

Coleman JN, Cadek M, Blake R, Nicolosi V, Ryan KP, Belton C, et al. High performance nanotube‐reinforced plastics: understanding the mechanism of strength increase. Adv Funct Mater. 2004;14:791–8.

González JA, Mazzobre MF, Villanueva ME, Díaz LE, Copello GJ. Chitin hybrid materials reinforced with graphene oxide nanosheets: chemical and mechanical characterisation. RSC Adv. 2014;4:16480–8.

González JA, Villanueva ME, Peralta Ramos ML, Pérez CJ, Piehl LL, Copello GJ. Chitin based hybrid composites reinforced with graphene derivatives: a nanoscale study. RSC Adv. 2015;5:63813–20.

Guo Y, Duan B, Zhou J, Zhu P. Chitin/graphene oxide composite films with enhanced mechanical properties prepared in NaOH/urea aqueous solution. Cellulose. 2014;21:1781–91.

Ramanathan T, Abdala AA, Stankovich S, Dikin DA, Herrera-Alonso M, Piner RD, et al. Functionalized graphene sheets for polymer nanocomposites. Nat Nanotechnol. 2008;3:327–31.

Niyogi S, Bekyarova E, Itkis ME, Mcwilliams JL, AndM AH, Haddon RC. Solution properties of graphite and graphene. J Am Chem Soc. 2006;128:7720–1.

Park S, Lee KS, Bozoklu G, Cai W, Nguyen ST, Ruoff RS. Graphene oxide papers modified by divalent ions-enhancing mechanical properties via chemical cross-linking. ACS Nano. 2008;2:572–8.

Feng Y, Zhang X, Shen Y, Yoshino K, Feng W. A mechanically strong, flexible and conductive film based on bacterial cellulose/graphene nanocomposite. Carbohydr Polym. 2012;87:644–9.

Han D, Yan L, Chen W, Li W, Bangal PR. Cellulose/graphite oxide composite films with improved mechanical properties over a wide range of temperature. Carbohydr Polym. 2011;83:966–72.

Jr WSH, Offeman RE. Preparation of graphitic oxide. J Am Chem Soc. 1958;80:1339.

Han Z, Tang Z, Li P, Yang G, Zheng Q, Yang J. Ammonia solution strengthened three-dimensional macro-porous graphene aerogel. Nanoscale. 2013;5:5462–7.

Segal LC, Creely J, Martin AEJ, Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J. 1959;29:786–94.

Lu Y, Sun Q, She X, Xia Y, Liu Y, Li J, et al. Fabrication and characterisation of α-chitin nanofibers and highly transparent chitin films by pulsed ultrasonication. Carbohydr Polym. 2013;98:1497–504.

Stankovich S, Piner RD, Nguyen SBT, Ruoff RS. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon N Y. 2006;44:3342–7.

Wu K, Yang W, Liu X, Jiao Y, Zhou C. Electrospun porous polyethersulfone (PES) fiber mats with high bilirubin adsorption capacity. Mater Lett. 2016;185:252–5.

Peng Y-T, Lo C-T. Electrospun porous carbon nanofibers as lithium ion battery anodes. J Solid State Electrochem. 2015;19:3401–10.

Fan X, Peng W, Li Y, Li X, Wang S, Zhang G, et al. Deoxygenation of exfoliated graphite oxide under alkaline conditions: a green route to graphene preparation. Adv Mater. 2008;20:4490–3.

Guo Y, Duan B, Cui L, Zhu P. Construction of chitin/graphene oxide hybrid hydrogels. Cellulose. 2015;22:2035–43.

Zong W, Chen J, Han W, Chen J, Wang Y, Wang W et al. Preparation of chitosan/amino multiwalled carbon nanotubes nanocomposite beads for bilirubin adsorption in hemoperfusion. J Biomed Mater Res. B Appl Biomater. 2018:106B:96–103.

Ma CF, Gao Q, Xia KS, Huang ZY, Han B, Zhou CG. Three-dimensionally porous graphene: A high-performance adsorbent for removal of albumin-bonded bilirubin. Colloids Surf B Biointerfaces. 2017;149:146–53.

Peng Q, Liu M, Zheng J, Zhou C. Adsorption of dyes in aqueous solutions by chitosan–halloysite nanotubes composite hydrogel beads. Microporous Mesoporous Mater. 2015;201:190–201.

Ho YS, McKay G. Pseudo-second order model for sorption processes. Process Biochem. 1999;34:451–65.

Langmuir I. The adsorption of gases on plane surfaces of glass, mica and platinum. J Chem Phys. 1918;40:1361–403.

Freundlich H. Of the adsorption of gases. Section II. Kinetics and energetics of gas adsorption. Introductory paper to section II. Trans Faraday Soc. 1932;28:195–201.

Wu S, Duan B, Zeng X, Lu A, Xu X, Wang Y, et al. Construction of blood compatible lysine-immobilized chitin/carbon nanotube microspheres and potential applications for blood purified therapy. J Mater Chem B. 2017;5:2952–63.

Li HZ, Fang GZ, Li JY, Ma YM, Ma YL, Jin ZL. Synthesis of polyethyleneimine-microcrystalline cellulose and its adsorption character for bilirubin. Chem Ind Prod. 2009;29:99–103.

Acknowledgements

This work was financially supported by Science and technology project of Guangdong Province (Grant no 2017B040404006).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Song, X., Cui, S., Li, Z. et al. Fabrication of chitin/graphene oxide composite sponges with higher bilirubin adsorption capacity. J Mater Sci: Mater Med 29, 108 (2018). https://doi.org/10.1007/s10856-018-6107-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-018-6107-8