Abstract

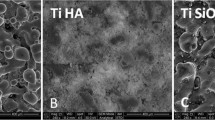

Tests on titanium alloys that possess low elastic modulus, corrosion resistance and minimal potential toxicity are ongoing. This study aimed to evaluate the behavior of human osteoblastic cells cultured on dense and porous Titanium (Ti) samples comparing to dense and porous Ti–35 Niobium (Ti–35Nb) samples, using gene expression analysis. Scanning electronic microscopy confirmed surface porosity and pore interconnectivity and X-ray diffraction showed titanium beta-phase stabilization in Ti–35Nb alloy. There were no differences in expression of transforming growth factor-β, integrin-β1, alkaline phosphatase, osteopontin, macrophage colony stimulating factor, prostaglandin E synthase, and apolipoprotein E regarding the type of alloy, porosity and experimental period. The experimental period was a significant factor for the markers: bone sialoprotein II and interleukin 6, with expression increasing over time. Porosity diminished Runt-related transcription factor-2 (Runx-2) expression. Cells adhering to the Ti–35Nb alloy showed statistically similar expression to those adhering to commercially pure Ti grade II, for all the markers tested. In conclusion, the molecular mechanisms of interaction between human osteoblasts and the Ti–35Nb alloy follow the principal routes of osseointegration of commercially pure Ti grade II. Porosity impaired the route of transcription factor Runx-2.

Similar content being viewed by others

References

Callister WD, Rethwisch DG. Mechanical properties of metals. Materials science and engineering: an introduction. 8th ed. Danvers: Wiley; 2010.

Ning C, Ding D, Dai K, Zhai W, Chen L. The effect of Zr content on the microstructure, mechanical properties and cell attachment of Ti-35Nb-xZr alloys. Biomed Mater. 2010;5(4):045006.

Niinomi M. Mechanical properties of biomedical titanium alloys. Mater Sci Eng A. 1998;243(1–2):231–6.

Dewidar MM, Yoon HC, Lim JK. Mechanical properties of metals for biomedical applications using powder metallurgy process: a review. Metal Mater Int. 2006;12(3):193–206.

Sumner DR, Galante JO. Determinants of stress shielding: design versus materials versus interface. Clin Orthop Relat Res. 1992;274:202–12.

Long M, Rack HJ. Titanium alloys in total joint replacement—a materials science perspective. Biomaterials. 1998;19(18):1621–39.

Niinomi M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater. 2008;1(1):30–42.

Khan MA, Williams RL, Williams DF. The corrosion behaviour of Ti-6Al-4V, Ti-6Al-7Nb and Ti-13Nb-13Zr in protein solutions. Biomaterials. 1999;20(7):631–7.

Davidson JA, Kovacs P, Davidson JA, et al. Biocompatible low modulus titanium alloy for medical implants. United States of America. 1992.

Santos DR, Pereira MS, Cairo CAA, Graca MLA, Henriques VAR. Isochronal sintering of the blended elemental Ti-35Nb alloy. Mater Sci Eng A. 2008;472(1–2):193–7.

Xiong J, Li Y, Hodgson PD, Wen C. In vitro osteoblast-like cell proliferation on nano-hydroxyapatite coatings with different morphologies on a titanium-niobium shape memory alloy. J Biomed Mater Res A. 2010;95A(3):766–73.

Boyan BD, Hummert TW, Dean DD, Schwartz Z. Role of material surfaces in regulating bone and cartilage cell response. Biomaterials. 1996;17(2):137–46.

Brunski JB. In vivo bone response to biomechanical loading at the bone/dental-implant interface. Adv Dent Res. 1999;13:99–119.

Pilliar RM, Deporter DA, Watson PA, Todescan R. The endopore implant-enhanced osseointegration with a sintered porous-surfaced design. Oral Health. 1998;88(7):61–4.

Deporter DA, Watson PA, Pilliar RM, Chipman ML, Valiquette NA. Histological comparison in the dog of porous-coated vs threaded dental implants. J Dent Res. 1990;69(5):1138–45.

Reis de Vasconcellos LM, Oliveira FN, Leite DO, et al. Novel production method of porous surface Ti samples for biomedical application. J Mater Sci Mater Med. 2012;23(2):357–64.

Dalby MJ, McCloy D, Robertson M, Wilkinson CDW, Oreffo ROC. Osteoprogenitor response to defined topographies with nanoscale depths. Biomaterials. 2006;27(8):1306–15.

Masaki C, Schneider GB, Zaharias R, Seabold D, Stanford C. Effects of implant surface microtopography on osteoblast gene expression. Clin Oral Implants Res. 2005;16(6):650–6.

Schwartz Z, Lohmann CH, Vocke AK, et al. Osteoblast response to titanium surface roughness and 1α, 25-(OH) 2D3 is mediated through the mitogen-activated protein kinase (MAPK) pathway. J Biomed Mater Res. 2001;56(3):417–26.

Reis de Vasconcellos LM, Moreira Barbara MA, Deco CP, et al. Healing of normal and osteopenic bone with titanium implant and low-level laser therapy (GaAlAs): a histomorphometric study in rats. Laser Med Sci. 2014;29(2):575–80.

Vasconcellos LMR, Carvalho YR, Prado RF, et al. Porous titanium by powder metallurgy for biomedical application: characterization, cell citotoxity and in vivo tests of osseointegration. In: Hudak R, Penhaker M, Majernik J, editors. Biomedical engineering: technical applications in medicine. 1st ed. Rijeka: InTech; 2012. p. 47–74.

Mailhot JM, Borke JL. An isolation and in vitro culturing method for human intraoral bone cells derived from dental implant preparation sites. Clin Oral Implant Res. 1998;9(1):43–50.

Beloti MM, Martins W Jr, Xavier SP, Rosa AL. In vitro osteogenesis induced by cells derived from sites submitted to sinus grafting with anorganic bovine bone. Clin Oral Implant Res. 2008;19(1):48–54.

Livak KJ, Schmittgen TD. Analysis of relative gene expression data using real-time quantitative PCR and the 2(-Delta Delta C(T)) Method. Methods. 2001;25(4):402–8.

Xu J, Weng X-J, Wang X, et al. Potential use of porous titanium-niobium alloy in orthopedic implants: preparation and experimental study of its biocompatibility in vitro. Plos One 2013;8(11).

Rosa AL, Crippa GE, de Oliveira PT, Taba M Jr, Lefebvre L-P, Beloti MM. Human alveolar bone cell proliferation, expression of osteoblastic phenotype, and matrix mineralization on porous titanium produced by powder metallurgy. Clin Oral Implant Res. 2009;20(5):472–81.

Sista S, Wen C, Hodgson PD, Pande G. The influence of surface energy of titanium-zirconium alloy on osteoblast cell functions in vitro. J Biomed Mater Res A. 2011;97A(1):27–36.

Navarro M, Michiardi A, Castano O, Planell JA. Biomaterials in orthopaedics. J R Soc Interface. 2008;5(27):1137–58.

Hsu HC, Hsu SK, Tsou HK, et al. Fabrication and characterization of porous Ti-7.5Mo alloy scaffolds for biomedical applications. J Mater Sci Mater Med. 2013;24(3):645–57.

Choi K, Kuhn JL, Ciarelli MJ, Goldstein SA. The elastic moduli of human subchondral, trabecular, and cortical bone tissue and the size-dependency of cortical bone modulus. J Biomech. 1990;23(11):1103–13.

Elmay W, Prima F, Gloriant T, et al. Effects of thermomechanical process on the microstructure and mechanical properties of a fully martensitic titanium-based biomedical alloy. J Mech Behav Biomed Mater. 2013;18:47–56.

Challa VS, Mali S, Misra RD. Reduced toxicity and superior cellular response of preosteoblasts to Ti-6Al-7Nb alloy and comparison with Ti-6Al-4V. J Biomed Mater Res A. 2013;101(7):2083–9.

Sista S, Wen C, Hodgson PD, Pande G. Expression of cell adhesion and differentiation related genes in MC3T3 osteoblasts plated on titanium alloys: role of surface properties. Mater Sci Eng C Mater Biol Appl. 2013;33(3):1573–82.

Lindner M, Bergmann C, Telle R, Fischer H. Calcium phosphate scaffolds mimicking the gradient architecture of native long bones. J Biomed Mater Res A. 2014;102(10):3677–84.

Isaac J, Galtayries A, Kizuki T, Kokubo T, Berda A, Sautier JM. Bioengineered titanium surfaces affect the gene-expression and phenotypic response of osteoprogenitor cells derived from mouse calvarial bones. Eur Cell Mater. 2010;20:178–96.

Kumar A, Bhat V, Balakrishnan M, et al. Bioactivity and surface characteristics of titanium implants following various surface treatments: an in vitro study. J Oral Implant. 2014. doi:10.1563/aaid-joi-D-13-00292.

Teixeira LN, Crippa GE, Lefebvre LP, et al. The influence of pore size on osteoblast phenotype expression in cultures grown on porous titanium. Int J Oral Maxillofac Surg. 2012;41(9):1097–101.

Caparros C, Guillem-Marti J, Molmeneu M, et al. Mechanical properties and in vitro biological response to porous titanium alloys prepared for use in intervertebral implants. J Mech Behav Biomed Mater. 2014;39:79–86.

Takemoto M, Fujibayashi S, Neo M, et al. Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials. 2005;26(30):6014–23.

Carinci F, Pezzetti F, Volinia S, et al. Analysis of MG63 osteoblastic-cell response to a new nanoporous implant surface by means of a microarray technology. Clin Oral Implant Res. 2004;15(2):180–6.

Cooper LF, Masuda T, Yliheikkila PK, Felton DA. Generalizations regarding the process and phenomenon of osseointegration. Part II. In vitro studies. Int J Oral Maxillofac Implant. 1998;13(2):163–74.

Ferraz EP, Sa JC, de Oliveira PT, et al. The effect of plasma-nitrided titanium surfaces on osteoblastic cell adhesion, proliferation, and differentiation. J Biomed Mater Res A. 2014;102(4):991–8.

Capellato P, Smith BS, Popat KC, Alves Claro APR. Fibroblast functionality on novel Ti-30Ta nanotube array. Mater Sci Eng C Mater Biol Appl. 2012;32(7):2060–7.

Hofstetter W, Sehr H, de Wild M, et al. Modulation of human osteoblasts by metal surface chemistry. J Biomed Mater Res A. 2013;101(8):2355–64.

Hughes FJ, Turner W, Belibasakis G, Martuscelli G. Effects of growth factors and cytokines on osteoblast differentiation. Periodontology. 2000;2006(41):48–72.

Hu Y, Tang XX, He HY. Gene expression during induced differentiation of sheep bone marrow mesenchymal stem cells into osteoblasts. Genet Mol Res. 2013;12:6527–34.

Pereira KK, Alves OC, Novaes AB, et al. Progression of osteogenic cell cultures grown on microtopographic titanium coated with calcium phosphate and functionalized with a type I collagen-derived peptide. J Periodontol. 2013;84(8):1199–210.

de Oliveira PT, Nanci A. Nanotexturing of titanium-based surfaces upregulates expression of bone sialoprotein and osteopontin by cultured osteogenic cells. Biomaterials. 2004;25(3):403–13.

Haynes DR, Rogers SD, Hay S, Pearcy MJ, Howie DW. The differences in toxicity and release of bone-resorbing mediators induced by titanium and cobalt-chromium-alloy wear particles. J Bone Joint Surg Am. 1993;75(6):825–34.

Acknowledgment

The authors thank FAPESP [São Paulo State Research Foundation] for the scholarship [PROC 2010/02778-0].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

do Prado, R.F., Rabêlo, S.B., de Andrade, D.P. et al. Porous titanium and Ti–35Nb alloy: effects on gene expression of osteoblastic cells derived from human alveolar bone. J Mater Sci: Mater Med 26, 259 (2015). https://doi.org/10.1007/s10856-015-5594-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5594-0