Abstract

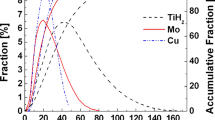

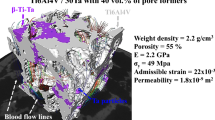

Porous titanium and its alloys are believed to be promising materials for bone implant applications, since they can reduce the “stress shielding” effect by tailoring porosity and improve fixation of implant through bone ingrowth. In the present work, porous Ti6Al4V alloys for biomedical application were fabricated by diffusion bonding of alloy meshes. Compressive mechanical behavior and compatibility in the range of physiological strain rate were studied under quasi-static and dynamic conditions. The results show that porous Ti6Al4V alloys possess anisotropic structure with elongated pores in the out-of-plane direction. For porous Ti6Al4V alloys with 60–70 % porosity, more than 40 % pores are in the range of 200–500 μm which is the optimum pore size suited for bone ingrowth. Quasi-static Young’s modulus and yield stress of porous Ti6Al4V alloys with 30–70 % relative density are in the range of 6–40 GPa and 100–500 MPa, respectively. Quasi-static compressive properties can be quantitatively tailored by porosity to match those of cortical bone. Strain rate sensitivity of porous Ti6Al4V alloys is related to porosity. Porous Ti6Al4V alloys with porosity higher than 50 % show enhanced strain rate sensitivity, which is originated from that of base materials and micro-inertia effect. Porous Ti6Al4V alloys with 60–70 % porosity show superior compressive mechanical compatibility in the range of physiological strain rate for cortical bone implant applications.

Similar content being viewed by others

References

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Progress Mater Sci. 2009;54:397–425.

Niinomi M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater. 2008;1:30–42.

Niinomi M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci Tech Adv Mater. 2003;4:445.

Duraccio D, Mussano F, Faga M. Biomaterials for dental implants: current and future trends. J Mater Sci. 2015;50:4779–812.

Gepreel M, Niinomi M. Biocompatibility of Ti-alloys for long-term implantation. J Mech Behav Biomed Mater. 2013;20:407–15.

Ryan G, Pandit A, Apatsidis DP. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials. 2006;27:2651–70.

Niinomi M, Nakai M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Inter J Biomater. 2011;2011:836587.

Nie L, Zhan Y, Hu T, Chen X, Wang C. β-Type Zr–Nb–Ti biomedical materials with high plasticity and low modulus for hard tissue replacements. J Mech Behav Biomed Mater. 2014;29:1–6.

Rao X, Chu CL, Zheng YY. Phase composition, microstructure, and mechanical properties of porous Ti–Nb–Zr alloys prepared by a two-step foaming powder metallurgy method. J Mech Behav Biomed Mater. 2014;34:27–36.

Jorgensen DJ, Dunand DC. Structure and mechanical properties of Ti–6Al–4 V with a replicated network of elongated pores. Acta Mater. 2011;59:640–50.

van Grunsven W, Goodall R, Reilly GC. Highly porous titanium alloy: fabrication and mechanical properties. J Biomech. 2012;45:S339.

Li F, Li J, Xu G, Liu G, Kou H, Zhou L. Fabrication, pore structure and compressive behavior of anisotropic porous titanium for human trabecular bone implant applications. J Mech Behav Biomed Mater. 2015;46:104–14.

Imwinkelried T. Mechanical properties of open-pore titanium foam. J Biomed Mater Res A. 2007;81A:964–70.

Li JC, Dunand DC. Mechanical properties of directionally freeze-cast titanium foams. Acta Mater. 2011;59:146–58.

Ahmadi SM, Campoli G, Amin Yavari S, Sajadi B, Wauthle R, Schrooten J, et al. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J Mech Behav Biomed Mater. 2014;34:106–15.

Cheng XY, Li SJ, Murr LE, Zhang ZB, Hao YL, Yang R, et al. Compression deformation behavior of Ti–6Al–4 V alloy with cellular structures fabricated by electron beam melting. J Mech Behav Biomed Mater. 2012;16:153–62.

Hsu H-C, Hsu S-K, Tsou H-K, Wu S-C, Lai T-H, Ho W-F. Fabrication and characterization of porous Ti–7.5Mo alloy scaffolds for biomedical applications. J Mater Sci Mater M. 2013;24:645–57.

Hansen U, Zioupos P, Simpson R, Currey JD, Hynd D. The effect of strain rate on the mechanical properties of human cortical bone. J Biomech Eng. 2008;130:011011.

Tuncer N, Arslan G. Designing compressive properties of titanium foams. J Mater Sci. 2009;44:1477–84.

Siegkas P, Tagarielli VL, Petrinic N, Lefebvre LP. The compressive response of a titanium foam at low and high strain rates. J Mater Sci. 2011;46:2741–7.

Carter DR, Hayes WC. Bone compressive strength: the influence of density and strain rate. Science. 1976;194:1174–6.

Shunmugasamy VC, Gupta N, Coelho PG. High strain rate response of rabbit femur bones. J Biomech. 2010;43:3044–50.

Kulin RM, Jiang F, Vecchio KS. Effects of age and loading rate on equine cortical bone failure. J Mech Behav Biomed Mater. 2011;4:57–75.

Kulin RM, Chen P-Y, Jiang F, Vecchio KS. A study of the dynamic compressive behavior of Elk antler. Mater Sci Eng C. 2011;31:1030–41.

Xue W, Krishna BV, Bandyopadhyay A, Bose S. Processing and biocompatibility evaluation of laser processed porous titanium. Acta Biomater. 2007;3:1007–18.

Fukuda A, Takemoto M, Saito T, Fujibayashi S, Neo M, Pattanayak DK, et al. Osteoinduction of porous Ti implants with a channel structure fabricated by selective laser melting. Acta Biomater. 2011;7:2327–36.

Gibson LJ, Ashby MF. Cellular solids, structure and properties. 2nd ed. Cambridge: Cambridge University Press; 1997.

Kitazono K, Takiguchi Y. Strain rate sensitivity and energy absorption of Zn–22Al foams. Scr Mater. 2006;55:501–4.

Deshpande VS, Fleck NA. High strain rate compressive behaviour of aluminium alloy foams. Int J Impact Eng. 2000;24:277–98.

Zhao H, Elnasri I, Abdennadher S. An experimental study on the behaviour under impact loading of metallic cellular materials. Int J Mech Sci. 2005;47:757–74.

Lee WS, Lin MT. The effects of strain rate and temperature on the compressive deformation behaviour of Ti-6Al-4 V alloy. J Mater Process Technol. 1997;71:235–46.

Vesenjak M, Veyhl C, Fiedler T. Analysis of anisotropy and strain rate sensitivity of open-cell metal foam. Mater Sci Eng A. 2012;541:105–9.

Thelen S, Barthelat F, Brinson LC. Mechanics considerations for microporous titanium as an orthopedic implant material. J Biomed Mater Res, Part A. 2004;69A:601–10.

Reid SR, Peng C. Dynamic uniaxial crushing of wood. Int J Impact Eng. 1997;19:531–70.

Calladine CR, English RW. Strain-rate and inertia effects in the collapse of two types of energy-absorbing structure. Int J Mech Sci. 1984;26:689–701.

Öhman C, Baleani M, Pani C, Taddei F, Alberghini M, Viceconti M, et al. Compressive behaviour of child and adult cortical bone. Bone. 2011;49:769–76.

Crowninshield RD, Pope MH. The response of compact bone in tension at various strain rates. Ann Biomed Eng. 1974;2:217–25.

Wright TM, Hayes WC. Tensile testing of bone over a wide range of strain rates: effects of strain rate, microstructure and density. Med Biol Eng. 1976;14:671–80.

Acknowledgments

This work was supported by National Basic Research Program of China (No. 2012CB619101), The Program of Introducing Talents of Discipline to Universities (No. B08040) and 2014 Shaanxi Provincial College Students’ Innovation and Entrepreneurship Training Plan (No. 0279).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, F., Li, J., Kou, H. et al. Compressive mechanical compatibility of anisotropic porous Ti6Al4V alloys in the range of physiological strain rate for cortical bone implant applications. J Mater Sci: Mater Med 26, 233 (2015). https://doi.org/10.1007/s10856-015-5565-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5565-5