Abstract

Proper mechanical properties are essential for the clinical application of magnesium-based implants. In the present work, a novel multilayer model composed of three layers with desirable features was developed. The modulus of the multilayer model can be adjusted by changing the thickness of each layer. To combine three layers and improve the corrosion resistance of the whole multilayer model, the polycaprolactone coating was employed. In the immersion test, pH values, the concentration of released magnesium ions, and weight loss indicate that the corrosion rate of multilayer models is considerable lower than that of the one-layer bare substrate. The three-point bending test, which is used to examine models’ mechanical properties, shows that the flexural modulus of multilayer models is reduced effectively. In addition, the mechanical degradation of multilayer models is more stable, compared to the one-layer substrate.

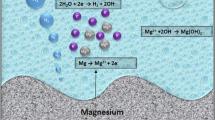

Graphical Abstract

Similar content being viewed by others

References

Zreiqat H, Howlett CR, Zannettino A, Evans P, Schulze-Tanzil G, Knabe C, et al. Mechanisms of magnesium-stimulated adhesion of osteoblastic cells to commonly used orthopaedic implants. J Biomed Mater Res B. 2002;62:175–84.

Yamasaki Y, Yoshida Y, Okazaki M, Shimazu A, Uchida T, Kubo T, et al. Synthesis of functionally graded MgCO3 apatite accelerating osteoblast adhesion. J Biomed Mater Res B. 2002;62:99–105.

Yamasaki Y, Yoshida Y, Okazaki M, Shimazu A, Kubo T, Akagawa Y, et al. Action of FGMgCO3Ap-collagen composite in promoting bone formation. Biomaterials. 2003;24:4913–20.

Zhang SX, Zhang XN, Zhao CL, Li JN, Song Y, Xie CY, et al. Research on an Mg–Zn alloy as a degradable biomaterial. Acta Biomater. 2010;6:626–40.

Zhou WR, Zheng YF, Leeflang MA, Zhou J. Mechanical property, biocorrosion and in vitro biocompatibility evaluations of Mg–Li–(Al)–(RE) alloys for future cardiovascular stent application. Acta Biomater. 2013;9:8488–98.

Lin X, Tan L, Zhang Q, Yang K, Hu Z, Qiu J, Cai Y. The in vitro degradation process and biocompatibility of a ZK60 magnesium alloy with a forsterite-containing micro-arc oxidation coating. Acta Biomater. 2013;9:8631–42.

Gu XN, Li N, Zhou WR, Zheng YF, Zhao X, Cai QZ, et al. Corrosion resistance and surface biocompatibility of a microarc oxidation coating on a Mg–Ca alloy. Acta Biomater. 2011;7:1880–9.

Hornberger H, Virtanen S, Boccaccini AR. Biomedical coatings on magnesium alloys—a review. Acta Biomater. 2012;8:2442–55.

Staiger MP, Pietak AM, Huadmai J, Dias G. Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials. 2006;27:1728–34.

Kuhlmann J, Bartsch I, Willbold E, Schuchardt S, Holz O, Hort N, Höche D, et al. Fast escape of hydrogen from gas cavities around corroding magnesium implants. Acta Biomater. 2013;9:8714–21.

Zhang S, Zhang X, Zhao C, Li J, Song Y, Xie C, Tao H, et al. Research on an Mg-Zn alloy as a degradable biomaterial. Acta Biomater. 2010;6:626–40.

Harper LT, Ahmed I, Felfel RM, Qian C. Finite element modelling of the flexural performance of resorbable phosphate glass fibre reinforced PLA composite bone plates. J Mech Behav Biomed. 2012;15:13–23.

Evans F. Factors affecting the mechanical properties of bone. Bull N Y Acad Med. 1973;49:751–64.

An Y, Draughn RA. Mechanical testing of bone and the bone–implant interface. New York: CRC Press; 1999.

Robertson DM, Pierre L, Chahal R. Preliminary observations of bone ingrowth into porous materials. J Biomed Mater Res A. 1976;10:335–44.

Head WC, Bauk DJ, Emerson RH Jr. Titanium as the material of choice for cementless femoral components in total hip arthroplasty. Clin Orthop Relat Res. 1995;311:85–90.

Ratner BD, Hoffman AS, Schoen FJ, Lemons JE. Biomaterials science: a multidisciplinary endeavour. San Diego: Elsevier Academic Press; 2004. p. 1–20.

Choudhary L, Singh Raman RK. Mechanical integrity of magnesium alloys in a physiological environment: slow strain rate testing based study. Eng Fract Mech. 2013;103:94–102.

Choudhary L, Szmerling J, Goldwasser R. Singh Raman RK, Investigations into stress corrosion cracking behaviour of AZ91D magnesium alloy in physiological environment. Proc Eng. 2011;10:518–23.

Choudhary L, Singh Raman RK. Magnesium alloys as body implants: fracture mechanism under dynamic and static loadings in a physiological environment. Acta Biomater. 2012;8:916–23.

Gu XN, Zhou WR, Zheng YF, Cheng Y, Wei SC, Zhong SP, et al. Corrosion fatigue behaviors of two biomedical Mg alloys—AZ91D and WE43—In simulated body fluid. Acta Biomater. 2010;6:4605–13.

Method for removal of corrosion products from corrosion test specimens of metals and alloys, ISO 8407:1991, London: ISO.

American Society for Testing and Materials (2004) ASTM-G31-72: standard practice for laboratory immersion corrosion testing of metals. In: Annual book of ASTM standards. Philadelphia: American Society for Testing and Materials.

Shapiro O. Bend testing. In: Kuhn H, Medlin D, editors. ASM handbook, vol. 8., Mechanical testing and evaluationMaterials Park: ASM International; 2000. p. 179–80.

Kalb H. Rzany a, Hensel B. Impact of microgalvanic corrosion on the degradation morphology of WE43 and pure magnesium under exposure to simulated body fluid. Corros Sci. 2012;57:122–30.

Song GL, Atrens A. Understanding magnesium corrosion—a framework for improved alloy performance. Adv Eng Mater. 2003;5:837–58.

Xin Y, Huo K, Tao H, Tang G, Chu PK. Influence of aggressive ions on the degradation behavior of biomedical magnesium alloy in physiological environment. Acta Biomater. 2008;4:2008–15.

Simaranov A, Sokolova I, Marshakov A, Mikhailovskii Y. Corrosion- electrochemical behavior of magnesium in acidic media, containing oxidants. Prot Metal. 1991;27:329–34.

Zong Y, Yuan GY, Zhang XB, Mao L, Niu JL, Ding WJ. Comparison of biodegradable behaviors of AZ31 and Mg–Nd–Zn–Zr alloys in Hank’s physiological solution. Mater Sci Eng B. 2012;25:395–401.

Yang LJ, Wei YH, Hou LF, Zhang D. Corrosion behaviour of die-cast AZ91D magnesium alloy in aqueous sulphate solutions. Corros Sci. 2010; 52: 345–51.

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities (XDJK2012C069). We thank Prof. Qing Li and Mr. Hong He (Senior Experimentalist) of the School of Materials Science and Engineering, Southwest University, for providing the mechanical property test.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, J., Huang, W., Li, Q. et al. A novel multilayer model with controllable mechanical properties for magnesium-based bone plates. J Mater Sci: Mater Med 26, 164 (2015). https://doi.org/10.1007/s10856-015-5504-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5504-5