Abstract

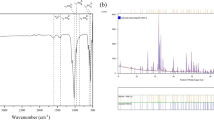

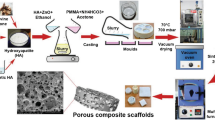

The use of tissue engineered biodegradable porous scaffolds has become an important focus of the biomedical research field. The precursor materials used to form these structures play a vital role in their overall performance thus making the study and synthesis of these selected materials imperative. The authors present a comparison and characterisation of hydroxyapatite (HA), a popular calcium phosphate (CaP) biomaterial, synthesised by an aqueous precipitation (AP) method. The influence of various reaction conditions on the phase, crystallinity, particle size as well as morphology, molecular structure, potential in-vivo bioactivity and cell viability were assessed by XRD, SEM and TEM, FTIR, a simulated body fluid (SBF) test and a live/dead assay using MC3T3 osteoblast precursor cells, respectively. Naturally carbonated nanoparticles of HA with typically needle-like morphology were synthesised by the reported AP method. Initial pH was found to influence the crystallisation process and determine the CaP phase formed as well as the resultant particle and crystallite sizes. A marked change in particle morphology was also observed above pH 9. The use of toluene as a replacement solvent for water up to 60 % was found to reduce the crystallinity of as-synthesised HA. This has marked influence on the effect of ethanolamine (5 wt%), which was found to improve HA crystallinity. SEM and EDS were used to confirm the growth of carbonated apatite on the surface of HA pellets immersed in SBF for up to 28 days. Cell culture results revealed viable cells on all samples where pH was controlled and maintained at 10–11 during precipitation, including those that used ethanolamine and toluene in preparation. When the initial alkali pH was not maintained non-viable cells were observed on HA substrates.

Similar content being viewed by others

References

Shepherd JH, Best SM. Calcium phosphate scaffolds for bone repair. JOM. 2011;63(4):83–92.

Kumta PN, et al. Nanostructured calcium phosphates for biomedical applications: novel synthesis and characterization. Acta Biomater. 2005;1(1):65–83.

Pramanik S, et al. Development of high strength hydroxyapatite by solid-state-sintering process. Ceram Int. 2007;33(3):419–26.

Rao RR, Roopa HN, Kannan TS. Solid state synthesis and thermal stability of HAP and HAP - beta-TCP composite ceramic powders. J Mater Sci-Mater Med. 1997;8(8):511–8.

Liu DM, Troczynski T, Tseng WJ. Water-based sol–gel synthesis of hydroxyapatite: process development. Biomaterials. 2001;22(13):1721–30.

Bezzi G, et al. A novel sol–gel technique for hydroxyapatite preparation. Mater Chem Phys. 2003;78(3):816–24.

Cunniffe GM, et al. The synthesis and characterization of nanophase hydroxyapatite using a novel dispersant-aided precipitation method. J Biomed Mater Res, Part A. 2010;95A(4):1142–9.

Ferraz MP, Monteiro FJ, Manuel CM. Hydroxyapatite nanoparticles: a review of preparation methodologies. J Appl Biomater Biomech. 2004;2(2):74–80.

Wang PP, et al. Effects of synthesis conditions on the morphology of hydroxyapatite nanoparticles produced by wet chemical process. Powder Technol. 2010;203(2):315–21.

Niu JL (2007) Hydrothermal synthesis of nano-crystalline hydroxyapatite. Bioceramics, Vol 19, Pts 1 and 2. 330–332: p. 247–250.

Wang YJ, et al. Investigations on the formation mechanism of hydroxyapatite synthesized by the solvothermal method. Nanotechnology. 2006;17(17):4405–12.

Lim GK, et al. Processing of hydroxyapatite via microemulsion and emulsion routes. Biomaterials. 1997;18(21):1433–9.

Yang JH, et al. Synthesis of spherical hydroxyapatite granules with interconnected pore channels using camphene emulsion. J Biomed Mater Res Part B. 2011;99B(1):150–7.

Rho JY, Kuhn-Spearing L, Zioupos P. Mechanical properties and the hierarchical structure of bone. Med Eng Phys. 1998;20(2):92–102.

Zhang LJ, Webster TJ. Nanotechnology and nanomaterials: promises for improved tissue regeneration. Nano Today. 2009;4(1):66–80.

Liu YK, et al. In vitro effects of nanophase hydroxyapatite particles on proliferation and osteogenic differentiation of bone marrow-derived mesenchymal stem cells. J Biomed Mater Res, Part A. 2009;90A(4):1083–91.

Huang J, et al. In vitro assessment of the biological response to nano-sized hydroxyapatite. J Mater Sci-Mater Med. 2004;15(4):441–5.

Sadat-Shojai M, et al. Synthesis methods for nanosized hydroxyapatite in diverse structures. Acta Biomaterialia. 2013;9(8):7591–621.

Cardoso DA, Jansen JA, Leeuwenburgh SCG. Synthesis and application of nanostructured calcium phosphate ceramics for bone regeneration. J Biomed Mater Res Part B. 2012;100B(8):2316–26.

Cao LY, Zhang CB, Huang HF. Synthesis of hydroxyapatite nanoparticles in ultrasonic precipitation. Ceram Int. 2005;31(8):1041–4.

Kong LB, Ma J, Boey F. Nanosized hydroxyapatite powders derived from coprecipitation process. J Mater Sci. 2002;37(6):1131–4.

Dorozhkin SV, Epple M. Biological and medical significance of calcium phosphates. Angewandte Chemie-International Edition. 2002;41(17):3130–46.

Driessens FCM. Formation and stability of calcium phosphates in relation to the phase composition of the mineral in calcified tissue. In: DeGroot K, editor. Bioceramics of calcium phosphate. Florida: CRC Press; 1983. p. 1–33.

Jha LJ, et al. Preparation and characterization of fluoride-substituted apatites. J Mater Sci-Mater Med. 1997;8(4):185–91.

Barralet J, Best S, Bonfield W. Carbonate substitution in precipitated hydroxyapatite: an investigation into the effects of reaction temperature and bicarbonate ion concentration. J Biomed Mater Res. 1998;41(1):79–86.

Barralet JE, Best SM, Bonfield W. Preparation and sintering of carbonate-substituted apatite. Bioceramics. 1993;6:179–84.

Bigi A, Boanini E, Gazzano M. Ionic substitutions in calcium phosphates synthesized at low temperature. Acta Biomater. 2010;6(6):1882–94.

Bouyer E, Gitzhofer F, Boulos MI. Morphological study of hydroxyapatite nanocrystal suspension. J Mater Sci-Mater Med. 2000;11(8):523–31.

LeGeros RZ, et al. Zinc effect on the in vitro formation of calcium phosphates: relevance to clinical inhibition of calculus formation. Am J Dent. 1999;12(2):65–71.

Aoki H (1991) Science and medical applications of hydroxyapatite. Ishiyaku Euroamerica.

Raynaud S, et al. Calcium phosphate apatites with variable Ca/P atomic ratio I. Synthesis, characterisation and thermal stability of powders. Biomaterials. 2002;23(4):1065–72.

Pang YX, Bao X. Influence of temperature, ripening time and calcination on the morphology and crystallinity of hydroxyapatite nanoparticles. J Eur Ceram Soc. 2003;23(10):1697–704.

Santos MH, et al. Synthesis control and characterization of hydroxyapatite prepared by wet precipitation process. Mater Res. 2004;7(4):625–30.

Slosarczyk A, Paszkiewicz Z, Paluszkiewicz C. FTIR and XRD evaluation of carbonated hydroxyapatite powders synthesized by wet methods. J Mol Struct. 2005;744:657–61.

Landi E, et al. Carbonated hydroxyapatite as bone substitute. J Eur Ceram Soc. 2003;23(15):2931–7.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27(15):2907–15.

Panda RN, et al. FTIR, XRD, SEM and solid state NMR investigations of carbonate-containing hydroxyapatite nano-particles synthesized by hydroxide–gel technique. J Phys Chem Solids. 2003;64(2):193–9.

Koutsopoulos S. Synthesis and characterization of hydroxyapatite crystals: a review study on the analytical methods. J Biomed Mater Res. 2002;62(4):600–12.

Bohner M. Calcium orthophosphates in medicine: from ceramics to calcium phosphate cements. Inj-Int J Care Inj. 2000;31:S37–47.

Afshar A, et al. Some important factors in the wet precipitation process of hydroxyapatite. Mater Des. 2003;24(3):197–202.

Girija EK, et al. Role of material processing on the thermal stability and sinterability of nanocrystalline hydroxyapatite. Powder Technol. 2012;225:190–5.

Salimi MN, et al. Effect of processing conditions on the formation of hydroxyapatite nanoparticles. Powder Technol. 2012;218:109–18.

Gross KA, Berndt CC (1991) Thermal spraying of hydroxyapatite for bioceramic applications. International ceramic conference: Austceram 90, 53–5: p. 124–129.

Liu DM. Fabrication of hydroxyapatite ceramic with controlled porosity. J Mater Sci-Mater Med. 1997;8(4):227–32.

Rehman I, Bonfield W. Characterization of hydroxyapatite and carbonated apatite by photo acoustic FTIR spectroscopy. J Mater Sci-Mater Med. 1997;8(1):1–4.

Legeros RZ, Bonel G, Legros R. Types of H2o in human enamel and in precipitated apatites. Calcif Tissue Res. 1978;26(2):111–8.

Yin G, et al. Impacts of the surface charge property on protein adsorption on hydroxyapatite. Chem Eng J. 2002;87(2):181–6.

Chen L, et al. The role of surface charge on the uptake and biocompatibility of hydroxyapatite nanoparticles with osteoblast cells. Nanotechnology. 2011;22(10):105708.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cox, S.C., Jamshidi, P., Grover, L.M. et al. Low temperature aqueous precipitation of needle-like nanophase hydroxyapatite. J Mater Sci: Mater Med 25, 37–46 (2014). https://doi.org/10.1007/s10856-013-5042-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-013-5042-y