Abstract

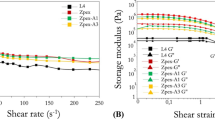

The aim of this study was to evaluate the effects of a simulated porcelain firing process on the surface, corrosion behavior and cell culture response of two nickel–chromium (Ni–Cr) dental alloys. A Be-free alloy and a Be-containing alloy were tested. Before porcelain firing, as-cast specimens were examined for surface composition using X-ray photoelectron spectroscopy and metallurgical phases using X-ray diffraction. Corrosion behaviors were evaluated using electrochemical impedance spectroscopy. 3T3 fibroblasts were cultured and exposed indirectly to specimens. MTT assays were counted after 3 and 6 days. The cell culture mediums exposed to specimens were analyzed for metal ion release. After porcelain firing, similar specimens were examined for the same properties. In both as-cast and fired conditions, the Be-free Ni–Cr alloy showed significantly more resistance to corrosion than the Be-containing Ni–Cr alloy, which exhibited BeNi phase. After porcelain firing, the corrosion resistance of the Be-free Ni–Cr alloy decreased statistically, corresponding with evident decreases of Cr and Ni oxides on the alloy surface. Also, the alloy’s MTT assay decreased significantly corresponding with an obvious increase of Ni-ion release after the firing. For the Be-containing Ni–Cr alloy, the firing process led to increases of surface oxides and metallic Be, while its corrosion resistance and cell culture response were not significantly changed after porcelain firing. The results suggested that the corrosion resistance and biocompatibility of the Be-free Ni–Cr alloy decreased after porcelain firing, whereas the firing process had little effect on the same properties of the Be-containing Ni–Cr alloy.

Similar content being viewed by others

References

Shiraishi T, Takuma Y, Fujita T, Miura E, Kunihiro H. Optical properties and microstructures of Pd-free Ag–Au–Pt–Cu dental alloys. J Mater Sci. 2009;44:2796–804.

Can G, Akpınar G, Aydın A. The release of elements from dental casting alloy into cell-culture medium and artificial saliva. Eur J Dent. 2007;1:86–90.

Palaskar J, Nadgir DV, Shah I. Effect of recasting of nickel–chromium alloy on its porosity. Contemp Clin Dent. 2010;1:237–42.

Craig RG, Powers JM. Restorative dental materials. 11th ed. St. Louis: Mosby; 2002.

Setcos JC, Babaei-Mahani A, Di Silvio L, Mjör IA, Wilson NHF. The safety of nickel containing dental alloys. Dent Mater. 2006;22:1163–8.

Bumgardner JD, Lucas LC. Surface analysis of nickel-chromium dental alloys. Dent Mater. 1993;9:252–9.

Gil FJ, Sánchez LA, Espías A, Planell JA. In vitro corrosion behaviour and metallic ion release of different prosthodontic alloys. Int Dent J. 1999;49:361–7.

Al-Hity RR, Kappert HF, Viennot S, Dalard F, Grosgogeat B. Corrosion resistance measurements of dental alloys, are they correlated? Dent Mater. 2007;23:679–87.

Johnson T, van Noort R, Stokes CW. Surface analysis of porcelain fused to metal systems. Dent Mater. 2006;22:330–7.

Roach MD, Wolan JT, Parsell DE, Bumgardner JD. Use of X-ray photoelectron spectroscopy and cyclic polarization to evaluate the corrosion behavior of six nickel–chromium alloys before and after porcelain-fused-to-metal firing. J Prosthet Dent. 2000;84:623–34.

Lin HY, Bowers B, Wolan JT, Cai Z, Bumgardner JD. Metallurgical, surface, and corrosion analysis of Ni–Cr dental casting alloys before and after porcelain firing. Dent Mater. 2008;24:378–85.

Qiu J, Yu WQ, Zhang FQ, Smales RJ, Zhang YL, Lu CH. Corrosion behaviour and surface analysis of a Co–Cr and two Ni–Cr dental alloys before and after simulated porcelain firing. Eur J Oral Sci. 2011;119:93–101.

Sarantopoulos DM, Beck KA, Holsen R, Berzins DW. Corrosion of Co–Cr and Ni–Cr dental alloys alloyed with palladium. J Prosthet Dent. 2011;105:35–43.

Hamdy AS, El-Shenawy E, El-Bitar T. Electrochemical impedance spectroscopy study of the corrosion behavior of some niobium bearing stainless steels in 3.5% NaCl. Int J Electrochem Sci. 2006;1:171–80.

Vander Wal RL, Bryg VM, Hays MD. XPS analysis of combustion aerosols for chemical composition, surface chemistry, and carbon chemical state. Anal Chem. 2011;83:1924–30.

Oliveira NT, Guastaldi AC. Electrochemical stability and corrosion resistance of Ti–Mo alloys for biomedical applications. Acta Biomater. 2009;5:399–405.

Aparicio C, Gil FJ, Fonseca C, Barbosa M, Planell JA. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 2003;24:263–73.

Viswanathan SSAJI, Han-Cheol CHOE. Electrochemical behavior of Co–Cr and Ni–Cr dental cast alloys. Trans Nonferrous Met Soc China. 2009;19:785–90.

Baran G. Auger chemical analysis of oxides on Ni–Cr alloys. J Dent Res. 1984;63:76–80.

Huang HH. Surface characterization of passive film on Ni–Cr-based dental casting alloys. Biomaterials. 2003;24:1575–82.

Silva JWJ, Sousa LL, Nakazato RZ, Codaro EN, Felipe H. Electrochemical and microstructural study of Ni–Cr–Mo alloys used in dental prostheses. Mater Sci Appl. 2011;2:42–8.

Ren X, Sridharan K, Allen TR. Corrosion behavior of alloys 625 and 718 in supercritical water. Corrosion. 2007;63:603–12.

Sharma M, Kumar AV, Singh N. Electrochemical corrosion behaviour of dental/implant alloys in saline medium. J Mater Sci Mater Med. 2008;19:2647–53.

Qiu J, Yu WQ, Zhang FQ. Effects of the porcelain-fused-to-metal firing process on the surface and corrosion of two Co–Cr dental alloys. J Mater Sci. 2011;46:1359–68.

Geurtsen W. Biocompatibility of dental casting alloys. Crit Rev Oral Biol Med. 2002;13:71–84.

Wataha JC, Lewis JB, Volkmann KR, Lockwood PE, Messer RL, Bouillaguet S. Sublethal concentrations of Au(III), Pd (II), and Ni(II) differentially alter inflammatory cytokine secretion from activated monocytes. J Biomed Mater Res B. 2004;69:11–7.

Lewis JB, Messer RL, McCloud VV, Lockwood PE, Hsu SD, Wataha JC. Ni(II) activates the Nrf2 signaling pathway in human monocytic cells. Biomaterials. 2006;27:5348–56.

Chen CY, Wang YF, Huang WR, Huang YT. Nickel induces oxidative stress and genotoxicity in human lymphocytes. Toxicol Appl Pharmacol. 2003;189:153–9.

Wang YF, Shyu HW, Chang YC, Tseng WC, Huang YL, Lin KH, Chou MC, Liu HL, Chen CY. Nickel (II)-induced cytotoxicity and apoptosis in human proximal tubule cells through a ROS-and mitochondria-mediated pathway. Toxicol Appl Pharmacol. 2012;259:177–86.

Issa Y, Brunton P, Waters CM, Watts DC. Cytotoxicity of metal ions to human oligodendroglial cells and human gingival fibroblasts assessed by mitochondrial dehydrogenase activity. Dent Mater. 2008;24:281–7.

Baričević M, Ratkaj I, Mladinić M, Zelježić D, Kraljević SP, Lončar B, Stipetić MM. In vivo assessment of DNA damage induced in oral mucosa cells by fixed and removable metal prosthodontic appliances. Clin Oral Investig. 2012;16:325–31.

Schmalz G, Garhammer P. Biological interactions of dental cast alloys with oral tissues. Dent Mater. 2002;18:396–406.

Wataha JC, Lockwood PE, Schedle A, Noda M. Ag, Cu, Hg and Ni ions alter the metabolism of human monocytes during extended low-dose exposures. J Oral Rehab. 2002;29:133–9.

Sailer I, Pjetursson BE, Zwahlen M, Hämmerle CH. A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part II: Fixed dental prostheses. Clin Oral Implants Res. 2007;18:86–96.

Acknowledgments

This work was supported by Natural Science Foundation of Higher Education Institutions of Jiangsu Province, China (Project Number: 11KJB320004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qiu, J., Tang, Cb., Zhu, Zj. et al. XPS and electrochemical impedance spectroscopy studies on effects of the porcelain firing process on surface and corrosion properties of two nickel–chromium dental alloys. J Mater Sci: Mater Med 24, 2519–2528 (2013). https://doi.org/10.1007/s10856-013-5004-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-013-5004-4