Abstract

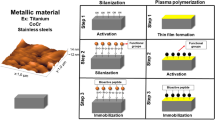

Surface immobilization with active functional molecules (AFMs) on a nano-scale is a main field in the current biomaterial research. The functionalization of a vast number of substances and molecules, ranging from inorganic calcium phosphates, peptides and proteins, has been investigated throughout recent decades. However, in vitro and in vivo results are heterogeneous. This may be attributed partially to the limits of the applied immobilization methods. Therefore, this paper highlights the advantages and limitations of the currently applied methods for the biological nano-functionalization of titanium-based biomaterial surfaces. The second part describes a newer immobilization system, using the nanomechanical fixation of at least partially single-stranded nucleic acids (NAs) into an anodic titanium oxide layer as an immobilization principle and their hybridization ability for the functionalization of the surface with active functional molecules conjugated to the respective complementary NA strands.

Similar content being viewed by others

References

Bozzini B, Carlino P, D’Urzo L, Pepe V, Mele C, Venturo F. An electrochemical impedance investigation of the behaviour of anodically oxidised titanium in human plasma and cognate fluids, relevant to dental applications. J Mater Sci Mater Med. 2008;19:3443–53.

Popa MV, Vasilescu E, Drob P, Vasilescu C, Demetrescu I, Ionita D. Long-term assessment of the implant titanium material—artificial saliva interface. J Mater Sci Mater Med. 2008;19:1–9.

Kamkin AN, Davydov AD, Fishgoit LA. The effects of the composition of titanium–aluminum alloy and anodic; oxide film on the breakdown potential in chloride and bromide solutions. Prot Met. 1996;32:214–6.

Esposito M, Hirsch JM, Lekholm U, Thomsen P. Biological factors contributing to failures of osseointegrated oral implants. II. Etiopathogenesis. Eur J Oral Sci. 1998;106:721–64.

van Steenberghe D, Jacobs R, Desnyder M, Maffei G, Quirynen M. The relative impact of local and endogenous patient-related factors on implant failure up to the abutment stage. Clin Oral Implant Res. 2002;13:617–22.

Johnsen SP, Sorensen HT, Lucht U, Soballe K, Overgaard S, Pedersen AB. Patient-related predictors of implant failure after primary total hip replacement in the initial, short and long-terms. A nationwide Danish follow-up study including 36,984 patients. J Bone Joint Surg Br. 2006;88:1303–8.

Kasemo B, Gold J. Implant surfaces and interface processes. Adv Dent Res. 1999;13:8–20.

Kasemo B, Lausmaa J. Surface science aspects on inorganic biomaterials. CRC Crit Rev Biocompat. 1986;2:335–80.

Vroman L, Adams AL. Identification of adsorbed protein films by exposure to antisera and water vapor. J Biomed Mater Res. 1969;3:669–71.

Ratner BD. A perspective on titanium biocompatibility. In: Brunette DM, Tengvall P, Textor M, Thomsen P, editors. Titanium in medicine. Berlin: Springer; 2001. p. 1–12.

Henry PJ. Comparative surface analysis of two osseointegrated implant systems. Int J Oral Maxillofac Implants. 1987;2:23–27.

Baleani M, Viceconti M, Toni A. The effect of sandblasting treatment on endurance properties of titanium alloy hip prostheses. Artif Organs. 2000;24(4):296–299.

Takeuchi M, Abe Y, Yoshida Y, Nakayama Y, Okazaki M, Kagawa Y. Acid pretreatment of titanium implants. Biomaterials. 2003;24:1821–1827.

Wang X, Hayakawab S, Tsurub K, Osaka A. Bioactive titania gel layers formed by chemical treatment of Ti substrate with a H2O2/HCl solution. Biomaterials. 2002;23:1353–1357.

Wang X, Hayakawa S, Tsuru K, Osaka A. Improvement of bioactivity of H2O2/TaCl5-treated titanium after subsequent heat treatments. J Biomed Mater Res. 2000;52:171–176.

Kokubo T, Ito S, Hayashi Z, Sakka S, Kitsugi T, Yamamuro T. Ca, P-rich layer formed on high-strength bioactive glass-ceramic A-W. J Biomed Mater Res. 1987;24:331–343.

Lee BH, Kim YD, Shin JH, Lee KH. Surface modification by alkali and heat treatments in titanium alloys. J Biomed Mater Res. 2002;61:466–473.

Kokubo T, Kim HM, Kawashita M. Novel bioactive materials with different mechanical properties. Biomaterials. 2003;24:2161–2175.

Fujibayashi S, Nakamura T, Nishiguchi S, Tamura S, Uchida M, Kim HM, Kokubo T. Bioactive titanium: effect of sodium removal on the bone-bonding ability of bioactive titanium prepared by alkali and heat treatment. J Biomed Mater Res. 2001;56:562–570.

Jonášová L, Müller FA, Helebrant A, Strnad J, Greil P. Biomimetic apatite formation on chemically treated titanium. Biomaterials. 2004;25:1187–1194.

Wang CX, Wang M, Zhou X. Nucleation and growth of apatite on chemically treated titanium alloy: an electrochemical impedance spectroscopy study. Biomaterials. 2003;24:3069–3077.

Wang CX, Wang M. Electrochemical impedance spectroscopy study of the nucleation and growth of apatite on chemically treated pure titanium. Mater Lett. 2002;54:30–36.

Liang F, Zhou L, Wang K. Enhancement of the bioactivity of alkali-heat treated titanium by pre-calcification. J Mater Sci Lett. 2003;22:1665–1667.

Jonášová L, Müller FA, Helebrant A, Strnad J, Greil P. Hydroxyapatite formation on alkali-treated titanium with different content of Na+ in the surface layer. Biomaterials. 2002;23:3095–3101.

Nishiguchi S, Kato H, Neo M, Oka M, Kim HM, Kokubo T, Nakamura T. Alkali- and heat-treated porous titanium for orthopedic implants. J Biomed Mater Res. 2001;54:198–208.

Dieudonne SC, van den Dolder J, de Ruijter JE, Paldan H, Peltola T, vant Hof MA, Happonen RP, Jansen JA. Osteoblast differentiation of bone marrow stromal cells cultured on silica gel and sol–gel-derived titania. Biomaterials. 2002;23:3041–3101.

Kim HW, Kim HE, Knowlesb JC. Fluor-hydroxyapatite sol-gel coating on titanium substrate for hard tissue implants. Biomaterials. 2004;25:3351–3358.

Ramires PA, Romito A, Cosentino F, Milella E. The influence of titania/hydroxyapatite composite coatings on in vitro osteoblasts behaviour. Biomaterials. 2001;22:1467–1474.

Sul YT, Johansson CB, Jeong Y, Albrektsson T. The electrochemical oxide growth behaviour on titanium in acid and alkaline electrolytes. Med Eng Phys. 2001;23:329–346.

Yerokhin AL, Nie X, Leyland A, Matthews A. Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti–6Al–4V alloy. Surf Coat Technol. 2000;130:195–206.

Takebe J, Itoh S, Okada J, Ishibashi K. Anodic oxidation and hydrothermal treatment of titanium results in a surface that causes increased attachment and altered cytoskeletal morphology of rat bone marrow stromal cells in vitro. J Biomed Mater Res. 2000;51:398–407.

Iwasaki Y, Saito N. Immobilization of phosphorylcholine polymers to Ti-supported vinyldimethylsilyl monolayers and reduction of albumin adsorption. Colloids Surf B. 2003;32:77–84.

Puleoa DA, Kissling RA, Sheu MS. A technique to immobilize bioactive proteins, including bone morphogenetic protein-4 (BMP-4), on titanium alloy. Biomaterials. 2002;23:2079–2087.

Tegoulia VA, Rao W, Kalambur AT, Rabolt JF, Cooper SL. Surface properties, fibrinogen adsorption and cellular interactions of a novel phosphorylcholine-containing self assembled monolayer on gold. Langmuir. 2001;17:4396–4404.

Orban J, Faucher KM, Diuhy RA, Chaikof EL. Cytomimetic biomaterials. 4. In-situ photopolymerization of phospholipids on an alkylated surface. Macromolecules. 2000;33:4205–4212.

Kenausis GL, Voros J, Elbert DL, Huang NP, Hofer R, Ruiz-Taylor L, Textor M, Hubbell JA, Spencer ND. Poly(l-lysine)-g-poly(ethylene glycol) layers on metal oxide surfaces: attachment mechanism and effects of polymer architecture on resistance to protein adsorption. J Phys Chem B. 2000;104:3298–3309.

Michel R, Lussi JW, Csucs G, Reviakine I, Danuser G, Ketterer B, Hubbell JA, Textor M, Spencer ND. Selective molecular assembly patterning: a new approach to micro- and nanochemical patterning of surfaces for biological applications. Langmuir. 2002;18:3281–3287.

Kweh SWK, Khor KA, Cheang P. An in vitro investigation of plasma sprayed hydroxyapatite (HA) coatings produced with flame-spheroidized feedstock. Biomaterials. 2002;23:775–785.

Liu X, Ding C, Chu PK. Mechanism of apatite formation on wollastonite coatings in simulated body fluids. Biomaterials. 2004;25:1755–1761.

Liu X, Ding C. Apatite formed on the surface of plasma-sprayed wollastonite coating immersed in simulated body fluid. Biomaterials. 2001;22:2007–2012.

Liu X, Tao S, Ding C. Bioactivity of plasma sprayed dicalcium silicate coatings. Biomaterials. 2002;23:963–968.

Liu X, Ding C. Plasma-sprayed wollastonite 2M/ZrO2 composite coating. Surf Coat Technol. 2003;172:270–278.

Khor KA, Li H, Cheang P. Characterization of the bone-like apatite precipitated on high velocity oxy-fuel (HVOF) sprayed calcium phosphate deposits. Biomaterials. 2003;24:769–775.

Khor KA, Li H, Cheang P. Significance of melt-fraction in HVOF sprayed hydroxyapatite particles, splats and coatings. Biomaterials. 2004;25:1177–1186.

Li H, Khor KA, Kumar R, Cheang P. Characterization of hydroxyapatiteynazo-zirconia composite coatings deposited by high velocity oxy fuel spray procedure. Surf Coat Technol. 2004;182:227–236.

Xu GC, Hibino Y, Nishimura Y, Yatsuzuka M. Hydrogenated amorphous carbon formation with plasma-immersion ion plating. Surf Coat Technol. 2003;169–170:299–302.

Uchida M, Nihira N, Mitsuo A, Toyoda K, Kubota K, Aizawa T. Friction and wear properties of CrAlN and CrVN films deposited by cathodic arc ion plating method. Surf Coat Technol. 2004;177–178:627–630.

Matsuea T, Hanabusab T, Ikeuchi Y. The structure of TiN films deposited by arc ion plating. Vacuum. 2002;66:435–439.

Leng YX, Chen JY, Zeng ZM, Tian XB, Yang P, Huang N, Zhou ZR, Chu PK. Properties of titanium oxide biomaterials synthesized by titanium plasma immersion ion implantation and reactive ion oxidation. Thin Solid Films. 2000;377–378:573–577.

Leng YX, Chen JY, Yang P, Sun H, Wan GJ, Huang N. Mechanical properties and platelet adhesion behavior of diamond- like films synthesized by pulsed vacuum arc plasma deposition. Surf Sci. 2003;531:177–184.

Maitz MF, Pham MT, Matz W, Reuther H, Steiner G, Richter E. Ion beam treatment of titanium surfaces for enhancing deposition of hydroxyapatite from solution. Biomol Eng. 2002;19:269–272.

Le Guehennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007;23:844–54.

Ogawa T, Nishimura I. Different bone integration profiles of turned and acid-etched implants associated with modulated expression of extracellular matrix genes. Int J Oral Maxillofac Implants. 2003;18:200–10.

Szmukler-Moncler S, Perrin D, Ahossi V, Magnin G, Bernard JP. Biological properties of acid etched titanium implants: effect of sandblasting on bone anchorage. J Biomed Mater Res B. 2004;68:149–59.

Schwartz Z, Raz P, Zhao G, Barak Y, Tauber M, Yao H, Boyan BD. Effect of micrometer-scale roughness of the surface of Ti6Al4V pedicle screws in vitro and in vivo. J Bone Joint Surg Am. 2008;90:2485–98.

Rupp F, Scheideler L, Olshanska N, de Wild M, Wieland M, Geis-Gerstorfer J. Enhancing surface free energy and hydrophilicity through chemical modification of microstructured titanium implant surfaces. J Biomed Mater Res A. 2006;76:323–34.

Krupa D, Baszkiewicz J, Kozubowski JA, Mizera J, Barcz A, Sobczak JW, Bilinski A, Rajchel B. Corrosion resistance and bioactivity of titanium after surface treatment by three different methods: ion implantation, alkaline treatment and anodic oxidation. Anal Bioanal Chem. 2005;381:617–25.

Borsari V, Fini M, Giavaresi G, Tschon M, Chiesa R, Chiusoli L, Salito A, Rimondini L, Giardino R. Comparative in vivo evaluation of porous and dense duplex titanium and hydroxyapatite coating with high roughnesses in different implantation environments. J Biomed Mater Res A. 2009;89A:550–60.

Feng B, Weng J, Yang BC, Qu SX, Zhang XD. Characterization of titanium surfaces with calcium and phosphate and osteoblast adhesion. Biomaterials. 2004;25:3421–8.

Gan L, Wang J, Tache A, Valiquette N, Deporter D, Pilliar R. Calcium phosphate sol-gel-derived thin films on porous-surfaced implants for enhanced osteoconductivity. Part II: Short-term in vivo studies. Biomaterials. 2004;25:5313–21.

Roßler S, Sewing A, Stolzel M, Born R, Scharnweber D, Dard M, Worch H. Electrochemically assisted deposition of thin calcium phosphate coatings at near-physiological pH and temperature. J Biomed Mater Res A. 2003;64:655–63.

Morra M. Biochemical modification of titanium surfaces: peptides and ECM proteins. Eur Cell Mater. 2006;12:1–15.

Dalsin JL, Lin L, Tosatti S, Voros J, Textor M, Messersmith PB. Protein resistance of titanium oxide surfaces modified by biologically inspired mPEG-DOPA. Langmuir. 2005;21:640–6.

Schuler M, Owen GR, Hamilton DW, de Wild M, Textor M, Brunette DM, Tosatti SGP. Biomimetic modification of titanium dental implant model surfaces using the RGDSP-peptide sequence: a cell morphology study. Biomaterials. 2006;27:4003–15.

Wach J, Malisova B, Bonazzi S, Tosatti S, Textor M, Zurcher S, Gademann K. Protein-resistant surfaces through mild dopamine surface functionalization. Chemistry. 2008;14:10579–84.

Zoulalian V, Monge S, Zurcher S, Textor M, Robin JJ, Tosatti S. Functionalization of titanium oxide surfaces by means of poly(alkyl-phosphonates). J Phys Chem B. 2006;110:25603–5.

Maddikeri RR, Tosatti S, Schuler M, Chessari S, Textor M, Richards RG, Harris LG. Reduced medical infection related bacterial strains adhesion on bioactive RGD modified titanium surfaces: a first step toward cell selective surfaces. J Biomed Mater Res A. 2008;84:425–35.

Zhao L, Chu PK, Zhang Y, Wu Z. Antibacterial coatings on titanium implants. J Biomed Mater Res B. 2009;91B:470–80.

Schliephake H. Bone growth factors in maxillofacial skeletal reconstruction. Int J Oral Maxillofac Surg. 2002;31:469–84.

Sodek J, Chen J, Kassigoi S, Nagata T, Zhang Q, McKee MD, Nanci A. Elucidating the functions of bone sialoprotein and osteopontin in bone formation. In: Slavkin H, Price P, editors. Chemistry and biology of mineralized tissues. Amsterdam: Elsevier; 1992. p. 297–306.

Klinger MM, Rahemtulla F, Prince CW, Lucas LC, Lemons JE. Proteoglycans at the bone–implant interface. Crit Rev Oral Biol Med. 1998;9:449–63.

Ruoslahti E. The RGD story: a personal account. Matrix Biol. 2003;22:459–65.

Nomizu M, Kim WH, Yamamura K, Utani A, Song S, Otaka A, Roller PP, Kleinman HK, Yamada Y. Identification of cell binding sites in the laminin 1 chain carboxyl-terminal globular domain by systematic screening of synthetic peptides. J Biol Chem. 1995;270:20583–90.

Valentin AH, Weber J. Receptor technology—cell binding to P-15: a new method of regenerating bone quickly and safely-preliminary histomorphometrical and mechanical results in sinus floor augmentations. Keio J Med. 2004;53:166–71.

Ahn J, Boyle NA, MacDonald MT, Janda KD. Peptidomimetics and peptide backbone modifications. Mini Rev Med Chem. 2002;2:463–73.

Guo K, Schafer R, Paul A, Ziemer G, Wendel HP. Aptamer-based strategies for stem cell research. Mini Rev Med Chem. 2007;7:701–5.

Guo K, Scharnweber D, Schwenzer B, Ziemer G, Wendel HP. The effect of electrochemical functionalization of Ti-alloy surfaces by aptamer-based capture molecules on cell adhesion. Biomaterials. 2007;28:468–74.

Junker R, Dimakis A, Thoneick M, Jansen JA. Effects of implant surface coatings and composition on bone integration: a systematic review. Clin Oral Implant Res. 2009;20:185–206.

Kim T, Jang J, Kim H, Knowles JC, Ku Y. Biomimetic approach to dental implants. Curr Pharm Des. 2008;14:2201–11.

Lappalainen R, Santavirta SS. Potential of coatings in total hip replacement. Clin Orthop Relat Res. 2005;430:72–9.

Schliephake H, Scharnweber D. Chemical and biological functionalization of titanium for dental implants. J Mater Chem. 2008;18:2404–14.

Raynor JE, Capadona JR, Collard DM, Petrie TA, Garcia AJ. Polymer brushes and self-assembled monolayers: versatile platforms to control cell adhesion to biomaterials (Review). Biointerphases. 2009;4:FA3–16.

Roßler S, Zimmermann R, Scharnweber D, Werner C, Worch H. Characterization of oxide layers on Ti6Al4V and titanium by streaming potential and streaming current measurements. Colloids Surf B. 2002;26:387–95.

Tosatti S, Paul SMD, Askendal A, VandeVondele S, Hubbell JA, Tengvall P, Textor M. Peptide functionalized poly(-lysine)-g-poly(ethylene glycol) on titanium: resistance to protein adsorption in full heparinized human blood plasma. Biomaterials. 2003;24:4949–58.

Kim H, Li L, Lee E, Lee S, Kim H. Fibrillar assembly and stability of collagen coating on titanium for improved osteoblast responses. J Biomed Mater Res A. 2005;75A:629–38.

Nagai M, et al. In vitro study of collagen coating of titanium implants for initial cell attachment. Dent Mater J. 2002;21:250–60.

Teng S, Lee E, Park C, Choi W, Shin D, Kim H. Bioactive nanocomposite coatings of collagen/hydroxyapatite on titanium substrates. J Mater Sci Mater Med. 2008;19:2453–61.

Roehlecke C, Witt M, Kasper M, Schulze E, Wolf C, Hofer A, Funk RW. Synergistic effect of titanium alloy and collagen type I on cell adhesion, proliferation and differentiation of osteoblast-like cells. Cells Tissues Organs. 2001;168:178–87.

Auernheimer J, Zukowski D, Dahmen C, Kantlehner M, Enderle A, Goodman SL, Kessler H. Titanium implant materials with improved biocompatibility through coating with phosphonate-anchored cyclic RGD peptides. ChemBioChem. 2005;6:2034–40.

Wikesjo UME, Qahash M, Polimeni G, Susin C, Shanaman RH, Rohrer MD, Wozney JM, Hall J. Alveolar ridge augmentation using implants coated with recombinant human bone morphogenetic protein-2: histologic observations. J Clin Periodontol. 2008;35:1001–10.

Liu Y, de Groot K, Hunziker EB. BMP-2 liberated from biomimetic implant coatings induces and sustains direct ossification in an ectopic rat model Y1. Bone. 2005;36:745–57.

Liu Y, Enggist L, Kuffer AF, Buser D, Hunziker EB. The influence of BMP-2 and its mode of delivery on the osteoconductivity of implant surfaces during the early phase of osseointegration. Biomaterials. 2007;28:2677–86.

Liu Y, Huse RO, de Groot K, Buser D, Hunziker EB. Delivery mode and efficacy of BMP-2 in association with implants. J Dent Res. 2007;86:84–9.

Schliephake H, Aref A, Scharnweber D, Bierbaum S, Sewing A. Effect of modifications of dual acid-etched implant surfaces on peri-implant bone formation. Part I: Organic coatings. Clin Oral Implant Res. 2009;20:31–7.

Bagno A, et al. Human osteoblast-like cell adhesion on titanium substrates covalently functionalized with synthetic peptides. Bone. 2006;40:693–9.

Xiao SJ, Textor M, Spencer ND, Wieland M, Keller B, Sigrist H. Immobilization of the cell-adhesive peptide Arg-Gly-Asp-Cys (RGDC) on titanium surfaces by covalent chemical attachment. J Mater Sci Mater Med. 1997;8:867–72.

Morra M, Cassinelli C, Cascardo G, Cahalan P, Cahalan L, Fini M, Giardino R. Surface engineering of titanium by collagen immobilization. Surface characterization and in vitro and in vivo studies. Biomaterials. 2003;24:4639–54.

Martin SM, Schwartz JL, Giachelli CM, Ratner BD. Enhancing the biological activity of immobilized osteopontin using a type-1 collagen affinity coating. J Biomed Mater Res A. 2004;70A:10–9.

Huang H, Zhao Y, Liu Z, Zhang Y, Zhang H, Fu T, Ma X. Enhanced osteoblast functions on RGD immobilized surface. J Oral Implantol. 2003;29:73–9.

Hofer R, Textor M, Spencer ND. Alkyl phosphate monolayers, self-assembled from aqueous solution onto metal oxide surfaces. Langmuir. 2001;17:4014–20.

Gnauck M, Jaehne E, Blaettler T, Tosatti S, Textor M, Adler HP. Carboxy-terminated oligo(ethylene glycol)-alkane phosphate: synthesis and self-assembly on titanium oxide surfaces. Langmuir. 2007;23:377–81.

Liu H, Venkataraman NV, Spencer ND, Textor M, Xiao S. Structural evolution of self-assembled alkane phosphate monolayers on TiO2. Chem Phys Chem. 2008;9:1979–81.

Spori DM, Venkataraman NV, Tosatti SGP, Durmaz F, Spencer ND, Zurcher Z. Influence of alkyl chain length on phosphate self-assembled monolayers. Langmuir. 2007;23:8053–60.

Philippin G, Delhalle J, Mekhalif Z. Comparative study of the monolayers of CH3–(CH2) n –SiCl3 and CH3–(CH2) n –PO(OH)2, n 1/4 4 and 13, adsorbed on polycrystalline titanium substrates. Appl Surf Sci. 2003;212–213:530–6.

Gao W, Dickinson L, Grozinger C, Morin FG, Reven L. Self-assembled monolayers of alkylphosphonic acids on metal oxides. Langmuir. 1996;12:6429–35.

Viornery C, Chevolot Y, Leonard D, Aronsson BO, Pechy P, Mathieu HJ, Descouts P, Gratzel M. Surface modification of titanium with phosphonic acid to improve bone bonding: characterization by XPS and ToF-SIMS. Langmuir. 2002;18:2582–9.

Zorn G, Gotman I, Gutmanas EY, Adadi R, Salitra G, Sukenik CN. Surface modification of Ti45Nb alloy with an alkylphosphonic acid; self-assembled monolayer. Chem Mater. 2005;17:4218–26.

Zorn G, Gotman I, Gutmanas EY, Adadi R, Sukenik CN. Surface modification of Ti45Nb alloy by immobilization of RGD peptide via self assembled monolayer. J Mater Sci Mater Med. 2007;18:1309–15.

Clair S, Variola F, Kondratenko M, Jedrzejowski P, Nanci A, Rosei F, Perepichka DF. Self-assembled monolayer of alkanephosphoric acid on nanotextured Ti. J Chem Phys. 2008;128:144–705.

Silverman BM, Wieghaus KA, Schwartz J. Comparative properties of siloxane vs. phosphonate monolayers on a key titanium alloy. Langmuir. 2005;21:225–8.

Mani G, Johnson DM, Marton D, Dougherty VL, Feldman MD, Patel D, Ayon AA, Agrawal CM. Stability of self-assembled monolayers on titanium and gold. Langmuir. 2008;24:6774–84.

Cheng X, Filiaggi M, Roscoe SG. Electrochemically assisted co-precipitation of protein with calcium phosphate coatings on titanium alloy. Biomaterials. 2004;25:5395–403.

Roßler S, Born R, Scharnweber D, Worch H, Sewing A, Dard M. Biomimetic coatings functionalized with adhesion peptides for dental implants. J Mater Sci Mater Med. 2001;12:871–7.

Scharnweber D, Flossel M, Born R, Worch H. Adjusting the chlorhexidine content of calcium phosphate coatings by electrochemically assisted co-deposition from aqueous solutions. J Mater Sci Mater Med. 2007;18:391–7.

Scharnweber D, Beutner R, Roessler S, Michael J, Schwenzer B. Using electrochemical approaches for bio surface engineering of titanium based implants. In: Karlinsey RL, editor. Recent developments in advanced medical and dental materials using electrochemical methodologies. India: Research Signpost; 2009. p. 101–62.

De Giglio E, Sabbatini L, Colucci S, Zambonin G. Synthesis, analytical characterization, and osteoblast adhesion properties on RGD-grafted polypyrrole coatings on titanium substrates. J Biomater Sci Polym Ed. 2000;11:1073–83.

De Giglio E, De Gennaro L, Sabbatini L, Zambonin G. Analytical characterization of collagen- and/or hydroxyapatite-modified polypyrrole films electrosynthesized on Ti-substrates for the development of new bioactive surfaces. J Biomater Sci Polym Ed. 2001;12:63–76.

Scharnweber D, Born R, Flade K, Roessler S, Stoelzel M, Worch H. Mineralization behaviour of collagen type I immobilized on different substrates. Biomaterials. 2004;25:2371–80.

Beutner R, Sewing A. Electrochemically supported immobilization of a cyclic peptide containing the RGD sequence on Ti6Al4V. Biomaterialien. 2007;8:25–31.

Aladjem A. Review: anodic oxidation of titanium and its alloys. J Mater Sci Mater Med. 1973;8:688–704.

Schutz RW. Surface treatments for expanding titanium alloy application limits: an overview. In: Gregory JK, Rack HJ, Eylon D, editors. Surface treatments for expanding titanium alloy application limits: an overview. Warrendale: The Minerals, Metals & Materials Society; 1997. p. 1–22.

Yao C, Webster TJ. Anodization: a promising nanomodification technique of titanium implants for orthopedic applications. J Nanosci Nanotechnol. 2006;6:2682–92.

Kunze J, Ghicov A, Hildebrand H, Macak JM, Traveira L, Schmuki P. Challenges in the surface analytical characterisation of anodic TiO2 films: a review. Z Phys Chem. 2005;219:1561–82.

Velten D, Schenk-Meuser K, Biehl V, Duschner H, Breme J. Characterization of thermal and anodic oxide layers on β- and on near-β-titanium alloys for biomedical application. Z Met. 2003;94(6):667–75.

Zhang M, Lin GQ, Dong C, Wen LS. Amorphous TiO2 films with high refractive index deposited by pulsed bias arc ion plating. Surf Coat Technol. 2007;201:7252–8.

Diebold U. The surface science of titanium dioxide. Surf Sci Rep. 2003;48:53–229.

Scharnweber D, Beutner R, Rossler S, Worch H. Electrochemical behavior of titanium-based materials: are there relations to biocompatibility? J Mater Sci Mater Med. 2002;13:1215–20.

Khalil N, Leach JSL. The anodic oxidation of valve metals. I. Determination of ionic transport numbers by alpha-spectrometry. Electrochim Acta. 1986;31:1279–85.

Seeman NC. Nucleic acid junctions and lattices. J Theor Biol. 1982;99:237–47.

Seeman NC. DNA engineering and its application to nanotechnology. Trends Biotechnol. 1999;17:437–43.

Seeman NC. DNA in a material world. Nature. 2003;421:427–31.

Park SH, Pistol C, Ahn SJ, Reif JH, Lebeck AR, Dwyer C, LaBean TH. Finite-size, fully addressable DNA tile lattices formed by hierarchical assembly procedures. Angew Chem. 2006;118:749–53.

Rothemund PWK. Folding DNA to create nanoscale shapes and patterns. Nature. 2006;440:297–302.

He Y, Ye T, Su M, Zhang C, Ribbe AE, Jiang W, Mao C. Hierarchical self-assembly of DNA into symmetric supramolecular polyhedra. Nature. 2008;452:198–201.

Andersen FF, et al. Assembly and structural analysis of a covalently closed nano-scale DNA cage. Nucleic Acids Res. 2008;36:1113–9.

Le JD, Pinto Y, Seeman NC, Musier-Forsyth K, Taton TA, Kiehl RA. DNA-templated self assembly of metallic nanocomponent arrays on a surface. Nano Lett. 2004;4:2343–7.

Yan H, Park SH, Finkelstein G, Reif JH, LaBean TH. DNA-templated self-assembly of protein arrays and highly conductive nanowires. Science. 2003;301:1882–4.

Alberti P, Bourdoncle A, Sacca B, Lacroix L, Mergny J. DNA nanomachines and nanostructures involving quadruplexes. Org Biomol Chem. 2006;4:3383–91.

Beissenhirtz MK, Willner I. DNA-based machines. Org Biomol Chem. 2006;4:3392–401.

Michael J, Beutner R, Hempel U, Scharnweber D, Worch H, Schwenzer B. Surface modification of titanium-based alloys with bioactive molecules using electrochemically fixed nucleic acids. J Biomed Mater Res B. 2007;80:146–55.

Michael J, Schonzart L, Israel I, Beutner R, Scharnweber D, Worch H, Hempel U, Schwenzer B. Conjugates of nucleic acids and the peptide GRGDSP for titanium implant surface modification. Bioconjug Chem. 2009;20:710–8.

Beutner R, Michael J, Forster A, Schwenzer B, Scharnweber D. Immobilization of oligonucleotides on titanium based materials by partial incorporation in anodic oxide layers. Biomaterials. 2009;30:2774–81.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article has been retracted due to plagiarism.

An erratum to this article can be found at http://dx.doi.org/10.1007/s10856-011-4459-4

About this article

Cite this article

Bhola, R., Su, F. & Krull, C.E. RETRACTED ARTICLE: Functionalization of titanium based metallic biomaterials for implant applications. J Mater Sci: Mater Med 22, 1147–1159 (2011). https://doi.org/10.1007/s10856-011-4305-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4305-8