Abstract

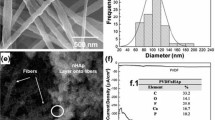

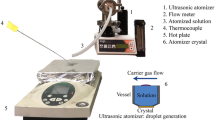

A chemically-etched titanium surface was modified by electrospinning a sol–gel-derived hydroxyapatite (HAp) that was subjected to calcination within the temperature range of 200–1400°C in the normative atmospheric condition. After heat treatment, crystal structures of the filmed titanium oxide and HAp on the titanium’s surface were identified using wide-angle X-ray diffraction. A highly porous layer of HAp was found to have formed on the oxidized titanium surfaces. The surfaces of three different samples; (1) electrospun HAp, (2) HAp calcined at 600°C, and (3) HAp calcined at 800°C, were investigated for their ability to foster promotion, proliferation, and differentiation of human osteoblasts (HOB) (in the 9th passage) in vitro up to 6 days. Among the three samples, cells cultured on the HAp calcined at 800°C titanium surfaces displayed the best results with regard to adhesion, growth, and proliferation of HOB. This novel method for fabrication of titanium substrates would provide a promising improvement for titanium-based medical devices over the current standards, which lack such substrates. These titanium substrates explicitly provide enhanced HOB proliferation in terms of both desired surface properties and their produced bulk quantity.

Similar content being viewed by others

References

Hala ZC, Rolfe H. Titanium substrata composition influences osteoblastic phenotype: in vitro study. J Biomed Mater Res. 1999;47:360–6.

Garcia-Alonso MC, Saldana L, Vallés G, Gonzalez-Carrasco JL, González-Cabrero J, Martínez ME, et al. In vitro corrosion behaviour and osteoblast response of thermally oxidized Ti6Al4V alloy. Biomaterials. 2003;24:19–26.

Bidez MW, Misch CE. Force transfer in implant dentistry: basic concepts and principles. J Oral Implantol. 1992;18:264–74.

Im KH, Lee SB, Kim KM, Lee YK. Improvement of bonding strength to titanium surface by sol–gel derived hybrid coating of hydroxyapatite and titania by sol–gel process. Surf Coat Technol. 2007;202:1135–8.

Michael MC. Dental implant materials: commercially pure titanium and titanium alloys. J Prosthodont. 1999;l8:40–3.

Fujibayashi S, Masashi N, Kim HM, Kokubo T, Nakamura T. Osteoinduction of porous bioactive titanium metal. Biomaterials. 2004;25:443–50.

Kasemo B, Lausmaa J. Biomaterial and implant surface: a surface science approach. Int J Oral Maxillofac Implants. 1988;3:247–59.

Xuanyong L, Paul KC, Chuanxian D. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R Rep. 2004;47:49–121.

Okumura M, Ohgushi H, Dohi Y, Katuda T, Tamai S, Koerten HK, et al. Osteoblastic phenotype expression on the surface of hydroxyapatite ceramics. J Biomed Mater Res. 1997;37:122–9.

Zhang C, Wang JX, Feng H, Lu B, Zhang X. Repairing segmental bone defects with living porous ceramic cylinders: an experimental study in dog femora. J Biomed Mater Res. 2001;55:28–32.

Li JP, Habibovica P, Doelc M, Wilsonb CE, Wijna JR, Clemens AV, et al. Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials. 2007;28:2810–20.

Kumta PN, Sfeir C, Lee DH, Olton D, Choi D. Nanostructured calcium phosphates for biomedical applications: novel synthesis and characterization. Acta Biomater. 2005;1:65–83.

Larsson C, Emanulesson L, Thomsen P, Ericson LE. Bone response to surface modified titanium implants—studies on the tissue response after 1 year to machined and electropolished implants with different oxide thicknesses. J Mater Sci Mater Med. 1997;8:721–9.

Feng B, Weng J, Yang BC, Qu SX, Zhang XD. Characterization of surface oxide films on titanium and adhesion of osteoblast. Biomaterials. 2003;24:4663–70.

Groessner-Schreiber B, Tuan RS. Enhanced extracellular matrix production an mineralization by osteoblasts cultured on titanium surfaces in vitro. J Cell Sci. 1992;101:209–17.

Barbara DB, Thomas WH, David DD, Zvi S. Role of material surfaces in regulating bone and cartilage cell response. Biomaterials. 1996;17:137–46.

Bajgai MP, Aryal S, Bhattarai SR, Remant Bahadur KC, Kim KW, Kim HY. Poly (ε-caprolactone) grafted dextran biodegradable electrospun matrix: a novel scaffold for tissue engineering. J Appl Polym Sci. 2008;108:1447–54.

Aryal S, Bajgai MP, Khil MS, Kang HS, Kim HY. Biomimetic hydroxyapatite particulate nanofiber modified silicon: in vitro bioactivity. J Biomed Mater Res. 2009;88A:384–91.

Hanawa T, Kamiura Y, Yamamoto S, Kohgo T, Amemiya A, Ukai H, et al. Early bone formation around calcium-ion-implanted titanium inserted into rat tibia. J Biomed Mater Res. 1997;36:131–6.

Li D, Ferguson SJ, Beutler T, Cochran DL, Sittig C, Hirt HP, et al. Biomechanical comparison of the sandblasted and acid etched and the machined and acid-etched titanium surface for dental implants. J Biomed Mater Res. 2002;60:325–32.

Frayssinet P, Tourenne F, Rouquet N, Conte P, Delga C, Bonel G. Comparative biological properties of HA plasma-sprayed coatings with different crystallinities. J Mater Sci Mater Med. 1994;5:11–7.

Cheung HS, McCarty DJ. Mitogenesis induced by calcium-containing crystals: role of intracellular dissolution. Exp Cell Res. 1985;157:63–70.

Pattanayak DK, Divya P, Upadhyay S, Prasad RC, Rao BT, Rama Mohan TR. Synthesis and evaluation of hydroxyapatite ceramics. Trends Biomater Artif Organs. 2005;18:87–92.

Chen W, McCarthy TJ. Layer-by-layer deposition: a tool for polymer surface modification. Macromolecules. 1997;30:78–86.

Stevens N, Priest CI, Sedev R, Ralston J. Wettability of photoresponsive titanium dioxide surfaces. Langmuir. 2003;19:3272–5.

Vihola H, Laukkanen A, Valtola L, Tenhu H, Hirvonen J. Cytotoxicity of thermosensitive polymers poly(N-isopropylacrylamide), poly(N-vinylcaprolactam) and amphiphilically modified poly-(N-vinylcaprolactam). Biomaterials. 2005;26:3055–64.

Groot K, Geesink R, Klein C, Serekian P. Plasma-sprayed coatings of hydroxyl apatite. J Biomed Mater Res. 1987;21:1375–81.

Acknowledgments

This research was supported by the Korean Research Foundation (KRF2007-211-D00032, Korean Government Project No. 10028211), Grant Funded by the Korean Government (MOEHRD), and Regional Research Centers Program of the Korean Ministry of Educational and Human Resources Development through the Center for Healthcare Technology Development, Chonbuk National University, Jeonju 562-756, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bajgai, M.P., Parajuli, D.C., Park, SJ. et al. In vitro bioactivity of sol–gel-derived hydroxyapatite particulate nanofiber modified titanium. J Mater Sci: Mater Med 21, 685–694 (2010). https://doi.org/10.1007/s10856-009-3902-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3902-2