Abstract

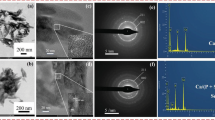

Electrophoretic deposition is a low-cost, simple, and flexible coating method for producing hydroxyapatite (HA) coatings on metal implants with a broad range of thicknesses, from < 1 μ m to > 500 μ m. As for many other HA coating techniques, densification of electrophoretically deposited coatings involves heating the coated metal to temperatures above 1000 ∘C. Metal substrates tend to react with HA coatings at such temperatures inducing decomposition at temperatures below 1050 ∘C (decomposition for pure HA normally occurs above 1300 ∘C). Therefore, densification of these coatings needs to be conducted at temperatures lower than 1050 ∘C, and this necessitates the use of high-surface-area HA nano-precipitates, rather than commercially available pre-calcined powders, which densify at temperatures typically higher than 1200 ∘C. HA nano-precipitates were prepared by three methods and deposited on metal substrates by electrophoresis: (1) the acid base method, which produced plate-like nano-particles with a 2.5:1 aspect ratio, and severely cracked coatings; (2) the calcium acetate method, which produced needle-like nano-particles with a 10:1 aspect ratio, and slightly cracked coatings; (3) the metathesis method, which produced rounded nano-particles with a 2:1 aspect ratio, and high-quality crack-free coatings. The results suggested that the less equiaxed the nano-particles, the more cracked the coatings obtained by the electrophoretic deposition technique.

Similar content being viewed by others

References

J. B. PARK and R. S. LAKES, “Biomaterials: An Introduction” (Plenum Press, New York, 1992).

A. RAVAGLIOLI and A. KRAJEWSKI, “Bioceramics: Materials, Properties, Applications“ (Chapman & Hall, London, 1992).

A. J. RUYS, N. EHSANI, B. K. MILTHORPE, K. HUSSLEIN, M. KOSCHIG and C. C. SORRELL, in Proceedings. Pacrim II: Second International Symposium of Pacific Rim Ceramic Societies, edited by P. A. Walls, C. C. Sorrell and A. J. Ruys (Australasian Ceramic Society, Cairns, 1997), p. 45.

K. A. GROSS, N. RAY and M. ROKKUM, J. Biomed. Mater. Res. 63 (2002) 106.

H. ZENG and W. R. LACEFIELD, ibid. 50 (2000) 239.

R. CHIESA, E. SANDRINI, M. SANTIN, G. RONDELLI and A. CIGADA, J. Appl. Biomat. Biomech. 1 (2003) 91.

A. MILEV, G. S. K. KANNANGARA and B. BEN-NISSAN, Mater. Lett. 57 (2003) 1960.

M. WEI, M. UCHIDA, H. KIM, T, KOKUBO and T. NAKAMURA, Biomater. 23 (2001) 167.

M. WEI, A. J. RUYS, B. K. MILTHORPE, C. C. SORRELL and J. H. EVANS, J. Sol-Gel Sci. Tech. 21 (2001) 39.

J. B. BIRKS and J. H. SCHULMAN, “Progress in Dielectrics. Volume I” (Heywood & Company Ltd., London, 1959).

M. WEI, A. J. RUYS, B. K. MILTHORPE and C. C. SORRELL, Mater. Eng. 9 (1998) 7.

A. J. RUYS, A. BRANDWOOD, B. K. MILTHORPE, M. R. DICKSON, K. A. ZEIGLER and C. C. SORRELL, J. Mater. Sci. Mater. Med. 6 (1995) 297.

A. J. RUYS, N. EHSANI, B. K. MILTHORPE and C. C. SORRELL, J. Aust. Ceram. Soc. 29 (1993) 65.

A. J. RUYS, K. A. ZEIGLER, B. K. MILTHORPE and C. C. SORRELL, in “Ceramics: Adding the Value,” edited by M. J. Bannister (CSIRO, Melbourne, 1992) p. 591.

P. DUCHEYNE, S. RADIN, M. HEUGHEBAERT and J. C. HEUGHEBAERT, Biomater. 11 (1990) 244.

A. J. RUYS, C. C. SORRELL, A. BRANDWOOD and B. K. MILTHORPE, J. Mater. Sci. Lett. 14 (1995) 744.

A. J. RUYS, M. WEI, C. C. SORRELL, M. R. DICKSON, A. BRANDWOOD and B. K. MILTHORPE, Biomater. 16 (1995) 409.

W. LI and L. GAO, Guocheng Gongcheng Xuebao 2 (2002) 305.

H. TAGAI and H. AOKI, “Mechanical Properties of Biomaterials” (John Wiley, New York, 1980).

B. F. YETER-DAL, V. GROSS and T. W. TURNEY, in “Ceramics: Adding the Value,” edited by M. J. Bannister (CSIRO, Melbourne, 1992) p. 617.

T. FUTAGAMI and T. OKAMOTO, J. Ceram. Soc. Japan. 95 (1987) 775.

M. JARCHO, C. H. BOLEN, M. B. THOMAS, J. BOBICK, J. F. KAY and R. H. DOREMUS, J. Mater. Sci. 11 (1976) 2027.

M. WEI, T. BOSTROM, L. GRØNDAHL and J. H. EVANS, J. Mater. Sci. Mater. Med. 14 (2003) 311.

K.-M. HUNG and W.-D. YANG, Mater. Manuf. Proc. 17 (2002) 323.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, M., Ruys, A.J., Milthorpe, B.K. et al. Precipitation of hydroxyapatite nanoparticles: Effects of precipitation method on electrophoretic deposition. J Mater Sci: Mater Med 16, 319–324 (2005). https://doi.org/10.1007/s10856-005-0630-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10856-005-0630-0