Abstract

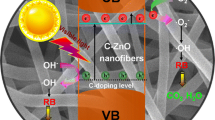

Ga2O3 is a semiconductor material with ultra-wide band gap (Eg = 4.9 eV), which has photocatalytic activity only under deep ultraviolet light irradiation (λ < 258 nm). In this study, Ga2O3/ZnO/WO3 double S-scheme heterojunction composite nanofibers were prepared by electrospinning method. The results show that the composite nanofibers have strong photocatalytic activity and sensitive response under UV–visible light irradiation. According to the heterojunction energy band matching theory of S-scheme, the photogenerated electrons (e−) of Ga2O3, ZnO, and WO3 are transferred from the valence band (VB) to the conduction band (CB), and photogenerated holes (h+) are generated in VB under the UV–visible light irradiation with sufficient energy. These factors (the internal electric field, band bending, and Coulomb attraction) are the driving forces to promote the useless e− and h+ are eliminated through recombination. Consequently, the powerful e− with strong reducing ability in the CB of Ga2O3 and the h+ with strong oxidizing ability in the VB of WO3 are preserved to engage in photocatalytic reactions. With Rhodamine B (Rh B) dye as the degradation target, the degradation efficiency of WO3, ZnO/WO3, and Ga2O3/ZnO/WO3 nanofibers were measured under UV–visible light irradiation for 120 min. The experimental results show that compared with WO3 and ZnO/WO3 nanofibers, Ga2O3/ZnO/WO3 composite nanofibers have the highest photocatalytic activity and excellent redox ability as photocatalyst. Besides, the response range of Ga2O3/ZnO/WO3 to the ultraviolet–visible spectrum is greatly expanded.

Similar content being viewed by others

References

M.N. Chong, B. Jin, C.W.K. Chow et al., Water Res. 44, 2997 (2010). https://doi.org/10.1016/j.watres.2010.02.039

R. Molinari, A. Caruso, T. Poerio, Catal. Today 144, 81 (2009). https://doi.org/10.1016/j.cattod.2009.02.034

R. Molinari, C. Lavorato, P. Argurio, Catal. Today 281, 144 (2017). https://doi.org/10.1016/j.cattod.2016.06.047

K.K. Philippe, R. Timmers, R. van Grieken et al., Ind. Eng. Chem. Res. 55, 2952 (2016). https://doi.org/10.1021/acs.iecr.5b04927

K.M. Zhang, Z.G. Wen, J. Environ. Manag. 88, 1249 (2008). https://doi.org/10.1016/j.jenvman.2007.06.019

D. Bahnemann, Sol. Energy 77, 445 (2004). https://doi.org/10.1016/j.solener.2004.03.031

M. Pelaez, N.T. Nolan, S.C. Pillai et al., Appl. Catal. B 125, 331 (2012). https://doi.org/10.1016/j.apcatb.2012.05.036

Y. Abdel-Maksoud, E. Imam, A. Ramadan, Catalysts 6, 138 (2016). https://doi.org/10.3390/catal6090138

Z.C. Zhao, C.L. Yang, Q.T. Meng et al., Spectrochim. Acta A 211, 71 (2019). https://doi.org/10.1016/j.saa.2018.11.039

R. Ito, M. Akatsuka, A. Ozawa et al., Bull. Chem. Soc. Jpn. 93, 694 (2020). https://doi.org/10.1246/bcsj.20190366

K. Maeda, K. Domen, J. Phys. Chem. Lett. 1, 2655 (2010). https://doi.org/10.1021/jz1007966

K.Z. Qi, B. Cheng, J.G. Yu et al., J. Alloys Compd. 727, 792 (2017). https://doi.org/10.1016/j.jallcom.2017.08.142

Y.L. Lai, M. Meng, Y.F. Yu et al., Appl. Catal. B 105, 335 (2011). https://doi.org/10.1016/j.apcatb.2011.04.028

C.B. Ong, L.Y. Ng, A.W. Mohammad, Renew. Sustain. Energy Rev. 81, 536 (2018). https://doi.org/10.1016/j.rser.2017.08.020

S.G. Kumar, K.S.R.K. Rao, Appl. Surf. Sci. 391, 124 (2017). https://doi.org/10.1016/j.apsusc.2016.07.081

A.K.L. Sajjad, S. Sajjad, A. Iqbal et al., Ceram. Int. 44, 9364 (2018). https://doi.org/10.1016/j.ceramint.2018.02.150

J.Y. Tsao, S. Chowdhury, M.A. Hollis et al., Adv. Electron. Mater. 4, 1600501 (2018). https://doi.org/10.1002/aelm.201600501

E. Chikoidze, A. Fellous, A. Perez-Tomas et al., Mater. Today Phys. 3, 118 (2017). https://doi.org/10.1016/j.mtphys.2017.10.002

S. Nakagomi, T. Sai, Y. Kokubun, Sens. Actuators B 187, 413 (2013). https://doi.org/10.1016/j.snb.2013.01.020

B. Zhao, F. Wang, H.Y. Chen et al., Adv. Funct. Mater. (2017). https://doi.org/10.1002/adfm.201700264

B. Das, B. Das, N.S. Das et al., Microporous Mesoporous Mater. (2019). https://doi.org/10.1016/j.micromeso.2019.109600

T. Shao, P.Y. Zhang, L. Jin et al., Appl. Catal. B 142, 654 (2013). https://doi.org/10.1016/j.apcatb.2013.05.074

T. Shao, P.Y. Zhang, Z.M. Li et al., Chin. J. Catal. 34, 1551 (2013). https://doi.org/10.1016/s1872-2067(12)60612-3

T. Yoshida, N. Yamamoto, T. Mizutani et al., Catal. Today 303, 320 (2018). https://doi.org/10.1016/j.cattod.2017.08.047

S.A. Lee, J.Y. Hwang, K. Ahn et al., Thin Solid Films 527, 45 (2013). https://doi.org/10.1016/j.tsf.2012.12.016

M.J. Li, Z.B. Yu, Y.P. Hou et al., Chem. Eng. J. 370, 1119 (2019). https://doi.org/10.1016/j.cej.2019.03.291

V. Iliev, D. Tomova, L. Bilyarska, J. Photochem. Photobiol. A 351, 69 (2018). https://doi.org/10.1016/j.jphotochem.2017.10.022

W.J. Li, D.Z. Li, S.G. Meng et al., Environ. Sci. Technol. 45, 2987 (2011). https://doi.org/10.1021/es103041f

J. Saini, V.K. Garg, R.K. Gupta et al., J. Environ. Chem. Eng. 5, 884 (2017). https://doi.org/10.1016/j.jece.2017.01.012

C. Gao, S.M. Chen, Y. Wang et al., Adv. Mater. (2018). https://doi.org/10.1002/adma.201704624

H.M. Gong, X.Q. Hao, Z.L. Jin et al., New J. Chem. 43, 19159 (2019). https://doi.org/10.1039/c9nj04584h

F.Y. Xu, K. Meng, B. Cheng et al., Nat. Commun. 11, 4613 (2020). https://doi.org/10.1038/s41467-020-18350-7

T. Pan, D.D. Chen, W.C. Xu et al., J. Hazard. Mater. 393, 122366 (2020). https://doi.org/10.1016/j.jhazmat.2020.122366

F. He, A.Y. Meng, B. Cheng et al., Chin. J. Catal. 41, 9 (2020). https://doi.org/10.1016/S1872-2067(19)63382-6

Q. Xie, W.M. He, S.W. Liu et al., Chin. J. Catal. 41, 140 (2020). https://doi.org/10.1016/S1872-2067(19)63481-9

H.N. Ge, F.Y. Xu, B. Cheng et al., ChemCatChem 11, 6301 (2019). https://doi.org/10.1002/cctc.201901486

Q.L. Xu, L.Y. Zhang, B. Cheng et al., Chem 6, 1543 (2020). https://doi.org/10.1016/j.chempr.2020.06.010

J. Liu, W. Lu, Q. Zhong et al., J. Colloid Interface Sci. 519, 255 (2018). https://doi.org/10.1016/j.jcis.2018.02.070

B. Subash, B. Krishnakumar, M. Swaminathan et al., J. Mol. Catal. A 366, 54 (2013). https://doi.org/10.1016/j.molcata.2012.09.008

X. Guo, H. Zhu, Q. Li, Appl. Catal. B 160, 408 (2014). https://doi.org/10.1016/j.apcatb.2014.05.047

H. Liu, H.Y. Hao, J. Xing et al., J. Mater. Sci. 51, 5872 (2016). https://doi.org/10.1007/s10853-016-9888-5

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, G., Zhang, H., Wang, R. et al. Preparation of Ga2O3/ZnO/WO3 double S-scheme heterojunction composite nanofibers by electrospinning method for enhancing photocatalytic activity. J Mater Sci: Mater Electron 32, 7307–7318 (2021). https://doi.org/10.1007/s10854-021-05441-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05441-4