Abstract

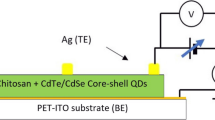

In this paper, a systematic study is carried out on mem-behavior of CdS, CdS@ZnS, and CdS@PbS core–shell nanocomposites with emphasis on the effect of ZnS and PbS shell on mem-behavior of CdS quantum dots. From X-ray diffraction, the CdS quantum dots are found to be hexagonal in nature with average crystallite size ~ 10.3 nm. From high-resolution transmission electron microscope images, the particle size is calculated around 3–4 nm for CdS quantum dots. For core–shell nanoparticles, formation of epitaxial shell layer on CdS core is clearly evident with enhancement in particle sizes. Active layer of as-synthesized samples is deposited on Indium tin oxide-coated glass which is used as one electrode. Aluminium is used as counter electrode and deposited over the active layer using thermal evaporation technique. The fabricated devices show bipolar switching characteristics with prominent hysteresis loops. The current–voltage characteristics of the devices show memristive, memcapacitive, and meminductive behavior depending on the type of active layer used. It is also observed that the inclusion of ZnS and \(\mathrm{PbS}\) shell significantly alters the mem-behavior of the CdS quantum dots which is the major finding of this study. The conduction through the device is found to be due to coulomb blockade which also supports the ON/OFF switching mechanism. The sensitivity of the devices can be determined from RON/ROFF ratio, and it is found to be higher for CdS@ZnS core–shell nanoparticles compared to CdS quantum dots and CdS@PbS nanoparticles.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- CdS:

-

Cadmium sulphide

- ZnS:

-

Zinc sulphide

- PbS:

-

Lead sulphide

- ZnO:

-

Zinc oxide

- CdSe:

-

Cadmium selenide

- Fe2O3 :

-

Ferric oxide

- R :

-

Resistor

- L :

-

Inductor

- C :

-

Capacitor

- PVA:

-

Polyvinyl alcohol

- q :

-

Charge

- Φ :

-

Magnetic flux

- Cu:

-

Copper

- ITO:

-

Indium tin oxide

- Al:

-

Aluminium

- PVP:

-

Polyvinylpyrrolidone

- QDs:

-

Quantum dots

- XRD:

-

X-ray diffraction

- UV–Vis:

-

Ultra violet–visible spectroscopy

- PL:

-

Photoluminescence spectroscopy

- FWHM:

-

Full width at half maximum

- HRTEM:

-

High-resolution transmission electron microscopy

- SAED:

-

Selected area electron diffraction

- EDS:

-

Energy-dispersive X-ray spectroscopy

- AFM:

-

Atomic force microscopy

- MR:

-

Memristive

- MC:

-

Memcapacitive

- MI:

-

Meminductive

- MEF:

-

Memristor efficiency factor

- HRS:

-

High resistance region

- LRS:

-

Low resistance region

- HWO:

-

Hysteresis width at ‘0V’

- CB:

-

Coulomb blockade

- RT:

-

Resonant tunneling

- NDR:

-

Negative differential resistance

References

L.O. Chua, IEEE Trans. Circuit Theory 18, 507 (1971)

D.B. Strukov, G.S. Snider, D.R. Stewart, R.S. Williams, Nature 453, 80 (2008)

A. Priyadharsan, S. Shanavas, C. Vidya, J. Kalyana Sundar, R. Acevedo, P.M. Anbarasan, Mater. Today 26, 3522–3525 (2019)

F. Flory, L. Escoubas, G. Berginc, J. of Nanophotonics 5(1), 052502 (2011)

P. Christian, F. Von der Kammer, M. Baalousha, T. Hofmann, Ecotoxicology 17(5), 326–343 (2008)

E.S. Kannan, G.H. Kim, D.A. Ritchie, J. Phys. D 43, 225101 (2010)

M. Russ, A. Lorke, D. Reuter, P. Schafmeister, Physica E 22, 506 (2004)

H. Das, P. Datta, J. Exp, Nanoscience 11(11), 901–915 (2016)

T.H. Kim, E.Y. Jang, N.J. Lee, D.J. Choi, K.-J. Lee, J.-T. Jang, J.-S. Choi, S.H. Moon, J. Cheon, Nano Lett. 9, 2229–2233 (2009)

R. Bhadra, P. Datta, K.C. Sharma, J. Dispers. Sci. Technol. 29(8), 1138–1142 (2008)

S. Sarma, B.M. Mothudi, M.S. Dhlamini, J. Mater. Sci. 27, 4551–4558 (2016)

P. Cheng, K. Sun, Y.H. Hu, Nano Lett. 16, 572–576 (2016)

S. Chakrabarti, A.J. Pal, Nanoscale 7, 9886–9893 (2015)

Y.C. Yang, F. Pan, Q. Liu, M. Liu, F. Zeng, Nano Lett. 9, 1636 (2009)

A. Younis, D. Chu, Xi. Lin, J. Yi, F. Dang, S. Li, ACS Appl. Mater. Interfaces 5, 2249–2254 (2013)

J. Devi, B. Das, S. Sarma, P. Datta, Indian J. Phys. 92, 1541–1550 (2018)

L.Q. Jiang, A. Khiat, I. Salaoru, C. Papavassiliou, X. Hui, T. Prodromakis, Sci. Rep. 4, 4522 (2014)

Do Hyeong Kim, Chaoxing Wu, Dong Hyun Park, Woo Kyum Kim, Hae WoonSeo, Sang Wook Kim and Tae Whan Kim. ACS Appl. Mater. Interfaces 10(17), 14843–14849 (2018)

J. Guo, S. Guo, X. Su, S. Zhu, Y. Pang, W. Luo, J. Zhang, H. Sun, H. Li, D. Zhang, ACS Appl Electron. Mater 2(3), 817–837 (2020)

F. Alibart, L. Gao, B.D. Hoskins, D.B. Strukov, Nanotechnology 23, 075201 (2012)

E. Goi, Q. Zhang, Xi. Chen, H. Luan, Gu. Min, PhotoniX 1, 3 (2020)

Fu. Tianda, X. Liu, H. Gao, J.E. Ward, X. Liu et al., Nat. Commun. 11, 1861 (2020)

Y. Hiruma, K. Yoshikawa, M.-A. Haga, Faraday Discuss 213, 99–113 (2019)

V.K. Sangwan, M.C. Hersam, Nat. Nanotechnol. 15, 517–528 (2020)

Y. Wang, Yu. Liutao, Wu. Si, Ru. Huang, Y. Yang, Adv. Intell. Syst. 2, 2000001 (2020)

B. Das, J. Devi, P.K. Kalita, P. Datta, J. Mater. Sci. 29, 546–557 (2018)

D. Das, A.M.P. Hussain, Appl. Phys. A 125, 826 (2019)

P. Scherrer, Göttinger Nachrichten Gesell. 2, 98 (1918)

J. Joo, H.B. Na, T. Yu, J.H. Yu et al., J. Am. Chem. Soc. 125(36), 11100–11105 (2003)

L.-W. Liu, S.-Y. Hu, Y. Pan, J.Q. Zhang et al., Beilstein J. Nanotechnol. 5, 919–926 (2014)

J. Mooney, M.M. Krause, J.I. Saari, P. Kambhampati, J. Chem. Phys. 138, 204705 (2013)

D.R. Baker, P.V. Kamat, Langmuir 26, 11272 (2010)

J. Tauc, Mater. Res. Bull. 3(1), 37–46 (1968)

S.D. Birajdar, A.B. Shinde, G.B. Kadam, P.M. Kshirsagar, M.N. Sarnaik, IJARBAS 2(1), 74–77 (2015)

P.K. Kalita, B. Das, R. Devi, J. Pure Appl. Chem. 4, 97–107 (2014)

N.S.M. Hadisa, A.A. Manafa, S.H. Ngalimc, S.H. Hermand, Sens Bio Sens Res 14, 21–29 (2017)

D.Y. Yun, T.W. Kim, S.W. Kim, Thin Solid Films 544, 433–436 (2013)

M.D. Ventra, Y.V. Pershin, L.O. Chua, Proc. IEEE 9, 1717 (2009)

S. Choi, P. Sheridan, W.D. Lu, Data Sci. Rep. 5, 10492 (2015)

T. Chang, S.H. Jo, K.-H. Ki, P. Sheridan, S. Gaba, W. Lu, Appl. Phys. A 102, 857–863 (2011)

Acknowledgements

The authors would like to thank CIF, Gauhati University for providing SEM and EDS analysis, SAIF, NEHU, Shillong for providing HRTEM and SAED facilities, CSR Indore Centre for AFM characterization, and SAIF Gauhati University for providing XRD facilities. The authors are grateful to the Energy, Emission and Environment research group, Huddersfield University, England, for their technical support.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All the experimental and theoretical works are done by ‘HD’. The paper is written by ‘HD’ and helped by ‘QX’. Technical guidance was provided by ‘QX’ and also some necessary modifications are done by him. This whole work is guided by ‘PD’ and theoretical concepts were introduced in the paper by her. All the three authors finally checked and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests in this section.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, H., Xu, Q. & Datta, P. Effect of ZnS and PbS shell on mem-behavior of CdS quantum dots. J Mater Sci: Mater Electron 32, 7049–7060 (2021). https://doi.org/10.1007/s10854-021-05415-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05415-6