Abstract

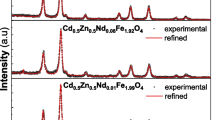

The pure and Ni-doped CuO nanocrystals were prepared via auto-combustion method and characterized by X-ray diffraction, scanning electron microscope, UV spectroscopy, and vibrating sample magnetometer method. The X-ray diffraction patterns of all samples revealed the monoclinic CuO nanocrystals with the nanocrystalline phase. XRD data revealed that the lattice constants of CuO nanocrystals were decreased with increasing Ni concentration which indicate that Ni2+ ions incorporated in CuO lattice. The average crystallite size of nanocrystals is intended by Scherer’s formula and found in the range of 21–24 nm. The variation of microstrain was investigated for pure and Ni-doped CuO samples. The SEM images exhibited that the prepared particles have spherical-like structure. The optical absorption spectra of the nanoparticles obtained using UV–Vis spectrophotometer show the blue-shift with increasing Ni doping. The optical band-gap energy increased with increasing Ni doping concentration due to the sp-d exchange interaction between d localized electrons of Ni. Magnetic measurement showed a ferromagnetic behavior at room temperature. Structural and magnetic properties are also discussed in detail.

Similar content being viewed by others

References

H. Ohno, D. Chiba, F. Matsukura, T. Omiya, E. Abe, T. Dietl, Y. Ohno, K. Ohtani, Nature 408, 944–946 (2000)

J. Cao, J. Wu, Mater. Sci. Eng. 71, 35–52 (2011)

C. Jing, Y. Jiang, W. Bai, J. Chu, A. Liu, J. Magn. Magn. Mater. 322, 2395–2400 (2010)

J.H. Yang, Y. Cheng, Y. Liu, X. Ding, Y.X. Wang, Y.J. Zhang, H.L. Liu, Solid State Commun. 149, 1164–1167 (2009)

Y. Matsumoto, M. Murakami, T. Shono, T. Hasegawa, T. Fukumura, M. Kawasaki, P. Ahmet, T. Chikyow, S.Y. Koshihara, H. Koinuma, Science 291, 854–856 (2001)

N. Theodoropoulou, A.F. Hebard, M.E. Overberg, C.R. Abernathy, S.J. Pearton, S.N.G. Chu, R.G. Wilson, Appl. Phys. Lett. 78, 3475–3477 (2001)

J.M.D. Coey, A.P. Douvalis, C.B. Fitzgerald, M. Venkatesan, Appl. Phys. Lett. 84, 1332–1334 (2004)

I. Singh, R.K. Bedi, Appl. Surf. Sci. 257, 7592–7599 (2011)

R. Sahay, J. Sundaramurthy, P. SureshKumar, V. Thavasi, S.G. Mhaisalkar, S. Ramakrishna, J. Solid State Chem. 186, 261–267 (2012)

L. Zheng, X. Liu, Mater. Lett. 61, 2222–2226 (2007)

Z. Gao, X. Liang, T. Pereira, R. Scaffaro, H.T. Hahn, Compos. Sci. Technol. 67, 2036–2044 (2007)

S. Dolai, R. Dey, S. Das, S. Hussain, R. Bhar, A.K. Pal, J. Alloys Compd. 724, 456–464 (2017)

M.K. Verma, V. Gupta, Sens. Actuators, B 166–167, 378–385 (2012)

H. Zou, S. Chen, Z. Liu, W. Lin, Powder Technol. 207, 238–244 (2011)

W.-Y. Sung, W.-J. Kim, S.-M. Lee, H.-Y. Lee, Y.-H. Kim, K.-H. Park, S. Lee, Vacuum 81, 851–856 (2007)

T. Jarlborg, Physica C 454, 5–14 (2007)

Z. Yin, Y. Ding, Q. Zhang, L. Guan, Electrochem. Commun. 20, 40–43 (2012)

W. Gao, S. Yang, S. Yang, L. Lv, Y. Du, Phys. Lett. A 375, 180–182 (2010)

L.M. Dwivedi, N. Shukla, K. Baranwal, S. Gupta, S. Siddique, V. Singh, J. Clust. Sci. (2020). https://doi.org/10.1007/s10876-020-01779-7

S.G. Bahoosh, A.T. Appostolov, I.N. Appostolova, J.M. Wesselinowa, Phys. Lett. A 376, 2252–2255 (2012)

D.P. Joseph, C. Venkateswaran, J. Korean Phys. Soc. 61, 449–454 (2012)

D. Shang, K. Yu, Y. Zhang, J. Xu, J. Wu, Y.E. Xu, L. Li, Z. Zhu, Appl. Surf. Sci. 255, 4093 (2009)

D. Gao, J. Zhang, J. Zhu, J. Qi, Z. Zhang, W. Sui, H. Shi, D. Xue, Nanoscale Res. Lett. 5, 769 (2010)

S. Hussain, A. Mumtaz, S. Hasanain, M. Usman, J. Appl. Phys. 111, 023908 (2012)

G.N. Rao, Y.D. Yao, J.W. Chen, IEEE Trans. Magn. 41, 3409 (2005)

A. Punnoose, H. Magnone, M.S. Seehra, J. Bonevich, Phys. Rev. B. 64, 174420 (2001)

S. Dolai, S.N. Sarangi, S. Hussain, R. Bhar, A.K. Pal, J. Magn. Magn. Mater. (2019). https://doi.org/10.1016/j.jmmm.2019.02.005

Y. Gülen, F. Bayansal, B. Şahin, H.A. Çetinkara, H.S. Güder, Ceram. Int. 39, 6475 (2013)

S. Horzum, A. Yildiz, N. Serin, T. Serin, Philos. Mag. 93, 3110–3117 (2013)

S.K. Kuanr, S. Nayak, K.S. Babu, Mater. Sci. Semicond. Process. 71, 268 (2017)

N.M. Basith, J.J. Vijaya, L.J. Kennedy, M. Bououdina, Mater. Sci. Semicond. Process. 17, 110 (2014)

S. Sen, S.K. Halder, S.P. Gupta, J. Phys. Soc. Jpn. 38, 1641–1647 (1975)

K.M. Racik, A. Manikandan, M. Mahendiran, P. Prabakaran, J. Madhavan, M.V.A. Rai, Physica E 119, 114033 (2020)

M. Chuai, Q. Zhao, T. Yang, Y. Luo, M. Zhang, Mater. Lett. 161, 205–207 (2015)

X. Yan, D. Hu, H. Li, L. Li, X. Chong, Y. Wang, Phys. B 406, 3956–3962 (2011)

S. Al-Amri, M.S. Ansari, S. Rafique, M. Aldhahri, S. Rahimuddin, A. Azam, A. Memic, Curr. Nanosci. 11, 191–197 (2015)

A. Punnoose, H. Magnone, M.S. Seehra, J. Bonevich, Phys. Rev. B 64, 174420 (2001)

S. Rehman, A. Mumtaz, S. Hasanain, J. Nano. Res. 13, 2497 (2011)

C.T. Meneses, J.G.S. Duque, L.G. Vivas, M. Knobel, J. Non-Cryst.Solids 354, 4830–4832 (2008)

T.I. Arbuzova, I.B. Smolyak, S.V. Naumov, A.A. Samokhvalov, Phys. Solid State 40, 1702–1705 (1998)

N.M. Basith, J.J. Vijaya, L.J. Kennedy, M. Bououdina, S. Hussain, J. Nanosci. Nanotechnol. 14(3), 2577–2583 (2014)

Acknowledgements

One of the authors, S. P. Kamble would like to acknowledge DST for the availability of instruments purchased under DST-FIST program at Chandmal Tarachand Bora College, Shirur Dist. Pune. (File no. SR/FST/College-068/2017). He is also thankful to the University Research Grant Scheme, BCUD, Savitribai Phule Pune University, Pune, MS India, for the award of the Research Project (File no. 15SCI000551).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamble, S.P., Mote, V.D. Optical and room-temperature ferromagnetic properties of Ni-doped CuO nanocrystals prepared via auto-combustion method. J Mater Sci: Mater Electron 32, 5309–5315 (2021). https://doi.org/10.1007/s10854-020-05106-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-05106-8