Abstract

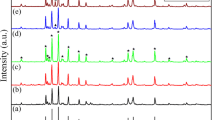

In this work, M-type hexagonal barium ferrites co-doped with Co and Zr atoms were prepared by a solid-phase method based on the sintering temperature and doping concentration. First, the influences of the sintering temperature on the crystal structure, microstructure, and magnetic properties of ferrites were studied. The crystallinity of the materials increases with the sintering temperature and obtaining high density and uniform grain size at 1300 °C, which promotes grain-boundary diffusion and suppresses grain-boundary migration. Second, the dependence of the crystal structure, microstructure, magnetic, and dielectric properties of Ba(CoxZrx)Fe12−2xO19 on the doping concentration (x = 0, 0.2, 0.4, 0.6) was investigated at sintering temperature of 1300 °C. The increase of the crystal parameter c with x value reveals that the ions of Co2+ and Zr4+ successfully replace the Fe3+ ions. Additionally, the co-doping ions of Co2+–Zr4+ promote the grain-boundary migration and result in some large size grain (> 20 mm) that appeared and increased with the doping concentration. The magnetic hysteresis loops reveal the saturation magnetization increases from 60.45 to 68.6 emu/g, and the coercivity decreases from 1800 to 190 Oe with the x increased to 0.6. The dielectric properties measurement displays the Co–Zr co-doping can improve the dielectric and reduce the dielectric loss. The highest value of the real part of permittivity (ε′) and the lowest value of the imaginary part of permittivity (ε″) can be obtained at a doping concentration of x = 0.4.

Similar content being viewed by others

References

R.C. Pullar, Prog. Mater. Sci. 57, 1191–1334 (2012)

V.G. Harris, A.S. Sokolov, J. Super. Nov. Magn. 32, 97–108 (2019)

V.G. Harris, IEEE Trans. Magn. 48(3), 1075–1104 (2012)

V.G. Harris, A. Geiler, Y.J. Chen, S.D. Yoon, M.Z. Wu, A. Yang, Z.H. Chen, P. He, P.V. Parimi, J. Magn. Magn. Mater. 321(14), 2035–2047 (2009)

V.G. Harris, Z.H. Chen, Y.J. Chen, S. Yoon, T. Sakai, A. Gieler, A. Yang, Y.X. He, J. Appl. Phys. 99(8), 547–583 (2006)

H. Sözeri, A. Baykal, B. Ünal, Phys. Status Solidi A 209(10), 2002–2013 (2012)

G.R. Amiri, M.H. Yousefi, M.R. Abolhassani, S. Manouchehri, M.H. Keshavarz, S. Fatahian, J. Magn. Magn. Mater. 323, 730–734 (2011)

S.K. Chawla, R.K. Mudsainiyan, S.S. Meena, S.M. Yusuf, J. Magn. Magn. Mater. 350, 23–29 (2014)

M. Jazirehpour, M.H. Shams, O. Khani, J. Alloys. Compd. 545, 32–40 (2012)

R.S. Alam, M. Moradi, M. Rostami, H. Nikmanesh, R. Moayedi, Y. Bai, J. Magn. Magn. Mater. 381, 1–9 (2015)

Z.F. Zi, Y.P. Sun, X.B. Zhu, Z.R. Yang, J.M. Dai, W.H. Song, J. Magn. Magn. Mater. 320, 2746–2751 (2008)

M. Jean, V. Nachbaur, J. Bran, J. Le Breton, J. Alloy. Compd. 496, 306 (2010)

T.G. Carreno, M.P. Morales, C. Serna, J. Mater. Lett. 43(3), 97–101 (2000)

S. Chaudhury, S.K. Rakshit, S.C. Parida, Z. Singh, K.D. Singh Mudher, V. Venugopal, J. Alloy. Compd. 455, 25–30 (2008)

V. Turchenko, A. Turkhanov, S. Trukhanov, I. Bobrikov, A.M. Balagurow, Eur. Phys. J. Plus. 131(4), 82 (2016)

M. Awawdeh, I. Bsoul, S.H. Mahmood, J. Alloy. Compd. 585, 465–473 (2014)

H. Sözeri, H. Deligöz, H. Kavas, A. Baykal, Ceram. Int. 40(6), 8645–8657 (2014)

X. Tang, Y. Yang, K. Hu, J. Alloy. Compd. 477(1), 488–492 (2009)

W.Y. Zhao, P. Wei, H.B. Cheng, X.F. Tang, Q.J. Zhang, J. Am. Ceram. Soc. 90(7), 2095–2103 (2007)

D. Chen, Y. Liu, Y. Li, W. Zhong, H. Zhang, J. Magn. Magn. Mater. 323, 2837 (2011)

V.V. Soman, V.M.D.K. NanotiKulkarni, Ceram. Int. 39, 5713–5723 (2013)

J. Li, H.W. Zhang, V.G. Harris, Y.L. Liao, Y.L. Liu, J. Alloy. Compd. 649, 782–787 (2015)

E.D. Solov’eva, E.V. Phshkova, A.E. Perekos, Inorg. Mater. 48, 1147–1152 (2012)

S.F. Wang, C.F. Zhang, G.G. Sun, B. Chen, W. Liu, X. Xiang, H. Wang, L.M. Fang, Q. Tian, Q.P. Ding, X.T. Zu, J. Sol-Gel Sci. Technol. 73, 371–378 (2015)

P. Kumar, A. Gaur, Ceram. Int. 43, 16403–16407 (2017)

H. Su, X.L. Tang, Z.Y. Zhong, J. Shen, J. Appl. Phys. 109, 07A501 (2011)

E.M. Zhou, H. Zheng, L. Zheng, P. Zheng, Z.H. Ying, X.J. Deng, Int. J. Appl. Ceram. Tec. 15, 1023–1029 (2018)

H. Zheng, M.G. Han, Y.H. Wu, L. Zheng, W.J. Zhao, L.J. Deng, H.B. Qin, IEEE. Trans. Nanotechnol. 17, 56–60 (2016)

L.H. Shao, S.Y. Shen, H. Zheng, P. Zheng, Q. Wu, L. Zheng, J. Electron. Mater. 47, 4085–4089 (2018)

N. Yasmin, M. Mirza, M. Safda, J. Magn. Magn. Mater. 446, 276–281 (2018)

T.B. Ghzaiel, W. Dhaoui, A. Pasko, F. Mazaleyrat, J. Alloys Compd. 671, 245–253 (2016)

R. Bhosale, R. Barkule, D. Shengule, K. Jadhav, J. Mater. Sci. 24(8), 3101–3107 (2013)

J. Li, S. He, K.Z. Shi, Ceram. Int. 44, 6953–6958 (2018)

R.K. Mudsainiyan, S.K. Chawla, S.S. Meena, J. Alloy. Compd. 615, 875–881 (2014)

C.S. Dong, X. Wang, P.H. Zhou, T. Liu, J.L. Xie, L.J. Deng, J. Magn. Magn. Mater. 354, 340–344 (2014)

C.Y. Liu, Y.J. Zhang, Y. Tang, Z.R. Wang, N. Ma, P.Y. Du, J. Mater. Chem. C. 5(14), 3461–3472 (2017)

R.K. Mudsainiyan, S.K. Chawla, S.S. Meena, N. Sharma, R. Singh, A. Das, Cer. Int. 40, 16617–16626 (2014)

A. Gruskova, J. Slama, A.G. Angeles, M. Soka, J. Elec. Eng. 63, 156 (2012)

Z.Ž Lazarević, Č Jovalekić, D.L. Sekulić, A. Milutinović, S. Baloš, M. Slankamenac, N.Ž Romčević, Mater. Res. Bull. 48, 4368–4378 (2013)

K.W. Wagner, Archiv f. Elektrotechnik. 2, 371–387 (1914)

H.C. Cao, H. Zheng, L.N. Fan, Z.F. Cheng, J.W. Zhou, Q. Wu, P. Zheng, L. Zheng, Y. Zhang, Int. J. Appl. Cream. Technol. 17, 812–821 (2020)

J.L. Jones, Mater. Sci. Eng. B. 167, 3–13 (2010)

D.J. Kim, J.Y. Jo, Y.S. Kim, Y.J. Chang, J.S. Lee, J.-G. Yoon, T.K. Song, T.W. Noh, Phys. Rev. Lett. 95, 237602 (2005)

N. Singh, A. Agarwal, S. Sanghi, S. Khasa, J. Magn. Magn. Mater. 324, 2506–2511 (2010)

S.S.N. Bharadwaj, J.R. Kim, H. Ogihar, L.E. Cross, S. Trolier-McKinstry, C.A. Randall, Phys. Rev. B. 83, 024106 (2011)

A.K. Pradhan, P.R. Mandal, K. Bera, S. Saha, T.K. Nath, Phys. B 525, 1–6 (2017)

Acknowledgements

This work is funded by the National Natural Science Foundation of China (Grant Nos. 51702075, 51771176), National Key Research and Development Project (Grant No. 2019YFF0217205).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Fan, L., Cao, H. et al. Microstructure, magnetic, and dielectric properties of Co–Zr co-doped hexagonal barium ferrites based on the sintering temperature and doping concentration. J Mater Sci: Mater Electron 32, 2685–2695 (2021). https://doi.org/10.1007/s10854-020-04761-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04761-1