Abstract

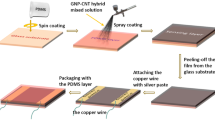

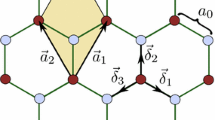

Flexible strain sensors have attracted great attention in the field of human health monitoring. Carbon nanotubes (CNTs) and graphene with outstanding electrical conductivity and nanoscale flexibility are often used in the field of stretchable strain sensor. Nevertheless, the combination of high sensitivity and a wide sensing range for stretchable strain sensors seems to be a dilemma. Here, a highly stretchable and sensitive strain sensor was prepared by simply dripping CNTs/graphene conductive composite on a pre-stretching silicon-containing elastomer. Pre-stretching is the key to enhancing the gauge factor (GF) and stretchability of the strain sensor. Compared with the CNTs/graphene coated elastomer without pre-stretching (GF = 4377.23), the GF of the CNTs/graphene coated elastomer with pre-stretching are significantly improved. GF of 28,752.95 (at strain of 23%) is achieved without sacrificing the stretchability at a prestrain coefficient (εpre) of 60%. graphene sheets are introduced as the conducting bridge among the adjacent CNTs to significantly improve the stability of the conductive network, thus forming a structure of line-to-plane electrical conduction pathway to provide the sensor with sufficient flexibility. The strain sensor exhibits excellent tensile properties (up to 400% strain) and ultra-high relative resistance change (ΔR/R0 = 14,719.41) over a wide sensing range (approximately 100% strain) with high durability and repeatability. The pre-stretching CNTs/graphene coated elastomer was then assembled at human joints for detection. The result shows that the strain sensor demonstrates potential applications in wearable electronic products.

Similar content being viewed by others

References

S. Chen, R. Wu, P. Li et al., ACS Appl. Mater. Interfaces 10, 37760 (2018). https://doi.org/10.1021/acsami.8b16591

J. Ge, L. Sun, F.-R. Zhang et al., Adv. Mater. 28, 722 (2016). https://doi.org/10.1002/adma.201504239

M. Amjadi, K.-U. Kyung, I. Park, M. Sitti, Adv. Funct. Mater. 26, 1678 (2016). https://doi.org/10.1002/adfm.201504755

J. Gao, X. Wang, W. Zhai et al., ACS Appl. Mater. Interfaces 10, 34592 (2018). https://doi.org/10.1021/acsami.8b11527

C.H. Gong, Y.X. Zhang, W. Chen et al., Adv. Sci. (2017). https://doi.org/10.1002/advs.201700231

M. Amjadi, A. Pichitpajongkit, S. Lee, S. Ryu, I. Park, ACS Nano 8, 5154 (2014). https://doi.org/10.1021/nn501204t

L. Ge, X.L. Gong, Y. Wang, S.H. Xuan, Compos. Sci. Technol. 135, 92 (2016). https://doi.org/10.1016/j.compscitech.2016.09.015

S.J. Kim, S. Mondal, B.K. Min, C.G. Choi, ACS Appl. Mater. Interfaces 10, 36377 (2018). https://doi.org/10.1021/acsami.8b11233

S. Kumar, B.G. Falzon, S.C. Hawkins, Carbon 149, 380 (2019). https://doi.org/10.1016/j.carbon.2019.04.044

X. Liu, W. Liu, Q. Xia, J. Feng, Y. Qiu, F. Xu, Composites A 121, 123 (2019). https://doi.org/10.1016/j.compositesa.2019.03.015

G. Shi, Z. Zhao, J.-H. Pai et al., Adv. Funct. Mater. 26, 7614 (2016). https://doi.org/10.1002/adfm.201602619

J. Zhou, X. Xu, H. Yu, G. Lubineau, Nanoscale 9, 604 (2017). https://doi.org/10.1039/c6nr08096k

Y. Wang, Y. Jia, Y. Zhou et al., J. Mater. Chem. C 6, 8160 (2018). https://doi.org/10.1039/c8tc02702a

H. Hosseini, M. Kokabi, S.M. Mousavi, Carbohydr. Polym. 201, 228 (2018). https://doi.org/10.1016/j.carbpol.2018.08.054

Y. Pang, H. Tian, L. Tao et al., ACS Appl. Mater. Interfaces 8, 26458 (2016). https://doi.org/10.1021/acsami.6b08172

C.H. Gong, K. Hu, X.P. Wang et al., Adv. Funct. Mater. (2018). https://doi.org/10.1002/adfm.201706559

M.S. Sadi, M. Yang, L. Luo, D. Cheng, G. Cai, X. Wang, Cellulose 26, 6179 (2019). https://doi.org/10.1007/s10570-019-02526-6

Z. Tang, S. Jia, F. Wang et al., ACS Appl. Mater. Interfaces 10, 6624 (2018). https://doi.org/10.1021/acsami.7b18677

Z. Cao, R. Wang, T. He, F. Xu, J. Sun, ACS Appl. Mater. Interfaces 10, 14087 (2018). https://doi.org/10.1021/acsami.7b19699

Y. Cheng, R. Wang, J. Sun, L. Gao, Adv. Mater. 27, 7365 (2015). https://doi.org/10.1002/adma.201503558

B. Yin, Y. Wen, T. Hong et al., ACS Appl. Mater. Interfaces 9, 32054 (2017). https://doi.org/10.1021/acsami.7b09652

X. Wang, S. Meng, M. Tebyetekerwa et al., Composites A 105, 291 (2018). https://doi.org/10.1016/j.compositesa.2017.11.027

D. Liu, Q. Shi, S. Jin, Y. Shao, J. Huang, InfoMat (2019). https://doi.org/10.1002/inf2.12036

P.C. Zhao, M.J. Ni, Y.T. Xu et al., Sens. Actuators B (2019). https://doi.org/10.1016/j.snb.2019.126997

X. Zhao, L.L. Xu, Q. Chen et al., Adv. Mater. Technol. (2019). https://doi.org/10.1002/admt.201900443

S. Pyo, J. Choi, J. Kim, Adv. Electron. Mater. 5, 20 (2019). https://doi.org/10.1002/aelm.201800737

X. Chen, J. Zhu, Q. Xi, W. Yang, Sens. Actuators B 161, 648 (2012). https://doi.org/10.1016/j.snb.2011.10.085

F. Zhang, Y. Feng, M. Qin et al., Adv. Funct. Mater. (2019). https://doi.org/10.1002/adfm.201901383

L. Zhao, K. Wang, W. Wei, L. Wang, W. Han, InfoMat 1, 407 (2019). https://doi.org/10.1002/inf2.12032

L.H. Li, H.Y. Xiang, Y. Xiong et al., Adv. Sci. (2018). https://doi.org/10.1002/advs.201800558

J. Gao, B. Li, X. Huang et al., Chem. Eng. J. 373, 298 (2019). https://doi.org/10.1016/j.cej.2019.05.045

J. Zhou, X. Xu, Y. Xin, G. Lubineau, Adv. Funct. Mater. (2018). https://doi.org/10.1002/adfm.201705591

X. Li, T. Hua, B. Xu, Carbon 118, 686 (2017). https://doi.org/10.1016/j.carbon.2017.04.002

S. Aziz, S.-H. Chang, Compos. Sci. Technol. 163, 1 (2018). https://doi.org/10.1016/j.compscitech.2018.05.012

L. Zhang, H. Kou, Q. Tan, G. Liu, W. Zhang, J. Xiong, J. Phys. D (2019). https://doi.org/10.1088/1361-6463/ab2c78

R. Xu, Y. Lu, C. Jiang et al., ACS Appl. Mater. Interfaces. 6, 13455 (2014). https://doi.org/10.1021/am502208g

X. Peng, K. Wu, Y. Hu et al., J. Mater. Chem. A 6, 23550 (2018). https://doi.org/10.1039/c8ta09322a

Q. Liu, J. Chen, Y. Li, G. Shi, ACS Nano 10, 7901 (2016). https://doi.org/10.1021/acsnano.6b03813

Y. Huang, X. He, L. Gao, Y. Wang, C. Liu, P. Liu, J. Mater. Sci. Mater. Electron. 28, 9495 (2017). https://doi.org/10.1007/s10854-017-6693-0

D. Kang, P.V. Pikhitsa, Y.W. Choi et al., Nature 516, 222 (2014). https://doi.org/10.1038/nature14002

S. Jung, J. Lee, T. Hyeon, M. Lee, D.-H. Kim, Adv. Mater. 26, 6329 (2014). https://doi.org/10.1002/adma.201402439

J. Kim, M. Lee, H.J. Shim et al., Nat. Commun. (2014). https://doi.org/10.1038/ncomms6747

Y. Zheng, Y. Li, K. Dai et al., Compos. Sci. Technol. 156, 276 (2018). https://doi.org/10.1016/j.compscitech.2018.01.019

Y. Chen, L. Hu, C. Li et al., InfoMat (2020). https://doi.org/10.1002/inf2.12075

G. Cai, J. Wang, K. Qian, J. Chen, S. Li, P.S. Lee, Adv. Sci. 4, 1600190 (2017). https://doi.org/10.1002/advs.201600190

L. Duan, D.R. D'Hooge, M. Spoerk, P. Cornillie, L. Cardon, ACS Appl. Mater. Interfaces 10, 22678 (2018). https://doi.org/10.1021/acsami.8b03967

M. Jian, K. Xia, Q. Wang et al., Adv. Funct. Mater. (2017). https://doi.org/10.1002/adfm.201606066

Acknowledgements

This work was financially supported by The National Natural Science Foundation of China and The Civil Aviation Administration of China (No. U1833118).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Tang, H., Li, A. et al. Extremely stretchable strain sensors with ultra-high sensitivity based on carbon nanotubes and graphene for human motion detection. J Mater Sci: Mater Electron 31, 12608–12619 (2020). https://doi.org/10.1007/s10854-020-03811-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03811-y