Abstract

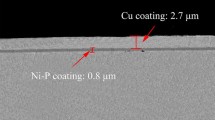

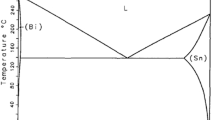

Effects of the Ni(P) plating thickness on interfacial reaction in the Sn–58Bi/Ni(P)/Cu joint system were revealed. It was found that the interfacial reaction was significantly influenced by the thickness of Ni(P) plating, and 0.1 μm Ni(P) plating completely transformed into Ni2SnP layer after soldering. This Ni2SnP layer not only provided a large number of diffusion channels but also reduced the solder joint reliability, demonstrating that 0.1 μm Ni(P) plating was not efficient in inhibiting the diffusion process between solder and substrate. However, the Ni(P) plating with thickness more than 0.5 μm could effectively inhibit atomic diffusion, and the Sn–Ni interaction would dominate the interfacial reaction instead of Cu–Sn phases. Although the Ni(P) plating with thickness of 0.5 μm partly transformed into Ni2SnP layer, the growth rate of compound layer was suppressed. In addition, the Ni3Sn4 would transform into (Cu,Ni)6Sn5 since Ni2SnP layer provided channels for Cu diffusing toward the solder/Ni3Sn4 interface. The Ni(P) plating with thickness of 1.5 μm remained integrated even after aging for 240 h, nonetheless, the excessive thickness of this barrier was unnecessary. Thus, it could be concluded that the appropriate thickness of Ni(P) plating should be controlled at 0.5–1.5 μm.

Similar content being viewed by others

References

X.Y. Bi, X.W. Hu, X.X. Jiang, Q.L. Li, Effect of Cu additions on mechanical properties of Ni3Sn4-based intermetallic compounds: first-principles calculations and nano-indentation measurements. Vacuum 164, 7–14 (2019)

C.-Y. Ho, J.-G. Duh, Quantifying the dependence of Ni(P) thickness in ultrathin-ENEPIG metallization on the growth of CueSn intermetallic compounds in soldering reaction. Mater. Chem. Phys. 148, 21–27 (2014)

X.Y. Bi, X.W. Hu, Q.L. Li, Investigations on elastic properties and electronic structures of α-CoSn3 doped with Ni via first-principles calculations and nano-indentation measurements. Results Phys. 15, 102607 (2019)

X.W. Hu, H. Qiu, X.X. Jiang, Effect of Ni addition into the Cu substrate on the interfacial IMC growth during the liquid-state reaction with Sn–58Bi solder. J. Mater. Sci.: Mater Electron. 30, 1907–1918 (2019)

K. Chung, Y.J. Chen, C.C. Li, C.R. Kao, The critical oxide thickness for Pb-free reflow soldering on Cu substrate. Thin Solid Films 20, 5346–5352 (2012)

W. Yang, J.Y. Wu, Z.X. Zhu, C.R. Kao, Effects of surface diffusion and reaction-induced volume shrinkage on morphological evolutions of micro joints. Mater. Chem. Phys. 191, 13–19 (2017)

J. Wang, S. Xue, P. Zhang, P. Zhai, Y. Tao, The reliability of lead-free solder joint subjected to special environment: a review. J. Mater. Sci.: Mater. Electron. 30, 9065–9086 (2019)

W. Seo, Y.-H. Ko, Y.-H. Kim, S. Yoo, Void fraction of a Sn-Ag-Cu solder joint underneath a chip resistor and its effect on joint strength and thermomechanical reliability. J. Mater. Sci.: Mater. Electron. 30, 15889–15896 (2019)

X. Hu, X. Yu, Y. Li, Q. Huang, Y. Liu, Z. Min, Effect of strain rate on interfacial fracture behaviors of Sn-58Bi/Cu solder joints. J. Mater. Sci. Mater. Electron. 25, 57–64 (2014)

H.Y. Qiu, X.W. Hu, X.X. Jiang, Q.L. Li, The effects of Ni addition on microstructure evolution and mechanical properties of solder joints undergoing solid-liquid electromigration. Mater. Lett. 256, 126609 (2019)

X. Deng, G. Piotrowski, J.J. Williams, N. Chawla, Influence of initial morphology and thickness of Cu6Sn5 and Cu3Sn intermetallics on growth and evolution during thermal aging of Sn-Ag solder/Cu joints. J. Electron. Mater. 32, 1403–1413 (2003)

P. Liu, P. Yao, J. Liu, Effects of multiple reflows on interfacial reaction and shear strength of SnAgCu and SnPb solder joints with different PCB surface finishes. J. Alloys Compd. 470, 188–194 (2009)

K.N. Tu, K. Zeng, Tin–lead (SnPb) solder reaction in flip chip technology. Mater. Sci. Eng. R.: Rep. 34, 1–58 (2001)

J.-W. Yoon, S.-W. Kim, S.-B. Jung, Effect of reflow time on interfacial reaction and shear strength of Sn-0.7Cu solder/Cu and electroless Ni(P) BGA joints. J. Alloys Compd. 385, 192–198 (2004)

C.E. Ho, C.W. Fan, W.Z. Hsieh, Pronounced effects of Ni(P) thickness on the interfacial reaction and high impact resistance of the solder/Au/Pd(P)/Ni(P)/Cu reactive system. Surf. Coat. Technol. 259, 244–251 (2014)

M. Sano, Y. Tahara, C.-Y. Chen, T.-F. Mark Chang, T. Hashimoto, H. Kurosu, T. Sato, M. Sone, Application of supercritical carbon dioxide in catalyzation and Ni-P electroless plating of nylon 6,6 textile. Surf. Coat. Technol. 302, 336–343 (2016)

C.-Y. Ho, J.-G. Duh, C.-W. Lin, C.-J. Lin, Y.-H. Wu, H.-C. Hong, T.-H. Wang, Microstructural variation and high-speed impact responses of Sn-3.0Ag-0.5Cu/ENEPIG solder joints with ultra-thin Ni-P deposit. J. Electron. Mater. 48, 2724–2732 (2013)

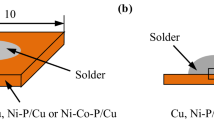

Y. Li, Z. Wang, X. Li, X. Hu, M. Lei, Growth behavior of IMCs layer of the Sn–35Bi–1Ag on Cu, Ni–P/Cu and Ni–Co–P/Cu substrates during aging. J. Mater. Sci.: Mater Electron. 30, 1519–1530 (2019)

C.E. Ho, L.H. Hsu, C.H. Yang, T.C. Yeh, P.T. Lee, Effect of Pd(P) thickness on the soldering reaction between Sn–3Ag–0.5Cu alloy and ultrathin-Ni(P)-type Au/Pd(P)/Ni(P)/Cu metallization pad. Thin Solid Films 584, 257–264 (2015)

I.K. Hong, H. Kim, S.B. Lee, Optimization of barrel plating process for electroless Ni–P plating. J. Ind. Eng. Chem. 20, 3767–3774 (2014)

A. Kumar, Z. Chen, S.G. Mhaisalkar, C.C. Wong, P.S. Teo, V. Kripesh, Effect of Ni-P thickness on solid-state interfacial reactions between Sn-3.5Ag solder and electroless Ni-P metallization on Cu substrate. Thin Solid Films 504, 410–415 (2006)

W.-R. Myung, Y. Kim, S.-B. Jung, Mechanical property of the epoxy-contained Sn–58Bi solder with OSP surface finish. J. Alloys Compd. 615, S411–S417 (2014)

M.G. Cho, K.W. Paik, H.M. Lee, S.W. Booh, T.-G. Kim, Interfacial reaction between 42Sn-58Bi solder and electroless Ni-P/immersion Au under bump metallurgy during aging. J. Electron. Mater. 35, 35–40 (2006)

X. Gu, K.C. Yung, Y.C. Chan, Thermomigration and electromigration in Sn-58Bi ball grid array solder joints. J. Mater. Sci.: Mater Electron. 21, 1090–1098 (2010)

T.L. Yang, J.Y. Wu, C.C. Li, S. Yang, C.R. Kao, Low temperature bonding for high temperature applications by using SnBi solders. J. Alloys Compd. 647, 681–685 (2015)

Z. Zhang, X.W. Hu, X.X. Jiang, Y.L. Li, Influences of mono-Ni(P) and dual-Cu/Ni(P) plating on the interfacial microstructure evolution of solder joints. Metall. Mater. Trans. A. 50, 480–492 (2019)

J.X. Cheng, X.W. Hu, X.X. Jiang, Interfacial reaction and IMC growth between Sn-37 Pb and heterogeneous dual-phase substrate. Vacuum 159, 112–124 (2019)

P.T. Vianco, J.A. Rejent, P.F. Hlava, Solid-state intermetallic compound layer growth between copper and 95.5Sn-3.9Ag-0.6Cu solder. J. Electron. Mater. 33, 991–1004 (2004)

M. He, Z. Chen, G. Qi, Solid state interfacial reaction of Sn-37Pb and Sn-3.5Ag solders with Ni-P under bump metallization. Acta Mater. 52, 2047–2056 (2004)

S.-M. Lee, J.-W. Yoon, S.-B. Jung, Interfacial reaction and mechanical properties between low melting temperature Sn-58Bi solder and various surface finishes during reflow reactions. J. Mater. Sci.: Mater. Electron. 26, 1649–1660 (2015)

C.E. Ho, T.T. Kuo, W. Gierlotka, F.M. Ma, Development and evaluation of direct deposition of Au/Pd(P) bilayers over Cu pads in soldering applications. J. Mater. Sci. 41, 3276–3283 (2012)

M.L. Huang, F. Yang, Solder size effect on early stage interfacial intermetallic compound evolution in wetting reaction of Sn3.0Ag0.5Cu/ENEPIG joints. J. Mater. Sci. Technol. 31, 252–256 (2015)

C.E. Ho, R.Y. Tsai, Y.L. Lin, C.R. Kao, Effect of Cu concentration on the reactions between Sn-Ag-Cu solders and Ni. J. Mater. Sci. 31, 584–590 (2002)

J.-W. Yoon, S.-W. Kim, S.-B. Jung, Effects of reflow and cooling conditions on interfacial reaction and IMC morphology of Sn–Cu/Ni solder joint. J. Alloys Compd. 415, 56–61 (2006)

M. Huang, F. Yang, N. Zhao, X. Liu, J. Wang, Study on size effect and cross-interaction in Cu/Sn/Ni-P interconnects. Int. Conf. Electron. Packag. Technol. (2014). https://doi.org/10.1109/isaf.2014.6917898

J. Li, S.H. Mannan, M.P. Clode, P.P. Conway, Interfacial reaction between molten Sn-Bi based solder and electroless Ni-P coatings for liquid solder interconnects. IEEE Trans. Compon. Packag. Technol. 31, 574–585 (2008)

T. Kadoguchi, N. Take, K. Yamanaka, S. Naga, K. Suganuma, Highly thermostable joint of a Cu/Ni-P plating/Sn-0.7Cu solder added with Cu balls. J. Mater. Sci. 52, 3244–3254 (2017)

M. He, W. HuaLau, G. Qi, Z. Chen, Intermetallic compound formation between Sn-3.5Ag solder and Ni-based metallization during liquid state reaction. Thin Solid Films 462, 376–383 (2004)

C.-H. Wang, J.-L. Liu, Effects of Sn thickness on morphology and evolution of Ni3Sn4 grains formed between molten Sn and Ni substrate. Intermetallics 61, 9–15 (2015)

J.W. Jang, D. Frear, D. Frear, T.Y. Lee, K.N. Tu, Morphology of interfacial reaction between lead-free solders and electroless Ni-P under bump metallization. J. Appl. Phys. 88, 6359–6363 (2000)

J.-W. Yoon, S.-W. Kim, S.-B. Jung, IMC morphology, interfacial reaction and joint reliability of Pb-free Sn–Ag–Cu solder on electrolytic Ni BGA substrate. J. Alloys Compd. 392, 247–252 (2005)

J.W. Xian, S.A. Belyakov, T.B. Britton, C.M. Gourlay, Heterogeneous nucleation of Cu6Sn5 in Sn–Cu–Al solders. J. Alloys Compd. 619, 345–355 (2015)

J.-W. Yoon, S.-B. Jung, Interfacial reactions between Sn-0.4Cu solder and Cu substrate with or without ENIG plating layer during reflow reaction. J. Alloys Compd. 396, 122–127 (2005)

D.-G. Kim, S.-B. Jung, Interfacial reactions and growth kinetics for intermetallic compound layer between In-48Sn solder and bare Cu substrate. J. Alloys Compd. 386, 151–156 (2005)

J. Shen, M. Zhao, P. He, Y. Pu, Growth behaviors of intermetallic compounds at Sn-3Ag-0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 574, 451–458 (2013)

D. Taneja, M. Volpert, F. Hodaj, Further insight into interfacial interactions in nickel/liquid Sn-Ag solder system at 230–350 °C. J. Mater. Sci. Mater. Electron. 28, 18366–18378 (2017)

J. Shen, Y.C. Chan, S.Y. Liu, Growth mechanism of Ni3Sn4 in a Sn/Ni liquid/solid interfacial reaction. Acta Mater. 57, 5196–5206 (2009)

C.-Y. Lin, C.-C. Jao, C. Lee, Y.-W. Yen, The effect of non-reactive alloying elements on the growth kinetics of the intermetallic compound between liquid Sn-based eutectic solders and Ni substrates. J. Alloys Compd. 440, 333–340 (2007)

J. Wang, L.G. Zhang, H.S. Liu, L.B. Liu, Z.P. Jin, Interfacial reaction between Sn-Ag alloys and Ni substrate. J. Alloys Compd. 455, 159–163 (2008)

S.K. Kang, V. Ramachandran, Growth kinetics of intermetallic phases at the liquid Sn and solid Ni interface. Scr. Metall. 14, 421–424 (1980)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51765040), Natural Science Foundation of Jiangxi Province (20192ACB21021), Outstanding Young talents funding of Jiangxi Province (20192BCB23002), the Innovative Funding for Graduate Students in Nanchang University (No. CX2019065) and the State Key Laboratory of Advanced Technologyies for Comprehensive Utilization of Platinum Metals (No. SKL-SPM-202022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, J., Hu, X., Zhang, Z. et al. Effects of the Ni(P) plating thickness on microstructure evolution of interfacial IMCs in Sn–58Bi/Ni(P)/Cu solder joints. J Mater Sci: Mater Electron 31, 11470–11481 (2020). https://doi.org/10.1007/s10854-020-03695-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03695-y