Abstract

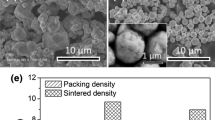

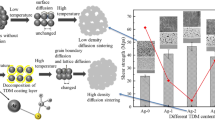

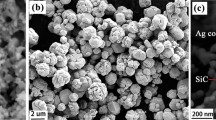

Sintering of silver is a popular method for forming interconnections in power electronics. Owing to their large size and spherical shape, micron- and submicron-sized Ag particles synthesized by a polyol method (denoted as polyol Ag particles) are not expected to undergo low-temperature, pressureless sintering. However, previous studies have shown sound bonding with shear strength of more than 40 MPa at 200 °C with micron and submicron polyol Ag particles. In this work, to understand the bonding mechanism of polyol Ag particles, the sintering behaviors of two Ag pastes, one with polyol Ag particles and another based on hybrid Ag particles consisting of micron-sized Ag flakes and submicron-sized Ag particles, were investigated without any applied pressure at 175 °C via transmission electron microscopy. During the sintering process, Ag nanoparticles formed in situ can significantly accelerate the sintering of the Ag paste, resulting in low electrical resistivity of the sintered Ag paste (9.8 × 10−6 Ω·cm) after only 5 min of sintering at 175 °C. The Ag nanoparticles were likely generated from the reduction of residual Ag ions or the Ag complex in the paste. The results were also verified by washing the Ag particles or adding Ag ions into the paste.

Similar content being viewed by others

References

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.S. Kim, M. Nogi, Microelectron. Reliab. 52, 375 (2012)

S. Magdassi, M. Grouchko, O. Berezin, A. Kamyshny, ACS Nano 4, 1943 (2010)

H. Schwarzbauer, R. Kuhnert, IEEE Trans. Ind. Appl. 27, 93–95 (1991)

K.S. Siow, J. Alloys Compd. 514, 6 (2012)

H. Zhang, Y. Gao, J. Jiu, K. Suganuma, J. Alloys Compd. 696, 123 (2017)

D. Wakuda, K.S. Kim, K. Suganuma, Scr. Mater. 59, 649 (2008)

D. Wakuda, K.S. Kim, K. Suganuma, I.E.E.E. Trans, Components Packag. Technol. 33, 437 (2010)

M.A. Asoro, D. Kovar, P.J. Ferreira, Chem. Commun. 50, 4835 (2014)

S. Soichi, K. Suganuma, I.E.E.E. Trans, Components Packag. Manuf. Technol. 3, 923 (2013)

J. Jiu, H. Zhang, S. Koga, S. Nagao, Y. Izumi, K. Suganuma, J. Mater. Sci. 26, 7183 (2015)

Y. Suzuki, T. Ogura, M. Takahashi, A. Hirose, Mater. Charact. 98, 186 (2014)

A.I. Boronin, V.I. Bukhityarov, A.L. Vishnevskii, G.K. Boreskov, V.I. Savchenko, Surf. Sci. 201, 195 (1988)

V.I. Bukhtiyarov, V.V. Kaichev, I.P. Prosvirin, J. Chem. Phys. 111, 2169 (2005)

Q. Xu, P. Pu, J. Zhao, C. Dong, C. Gao, Y. Chen, J. Mater. Chem. A 3, 542 (2015)

L. Fan, S. Qiao, W. Song, M. Wu, X. He, X. Qu, Electrochim. Acta 105, 299 (2013)

T. Zhao, R. Sun, S. Yu, Z. Zhang, L. Zhou, H. Huang, R. Du, Colloids Surf A 366, 197 (2010)

J.F. Weaver, G.B. Hoflund, Chem. Mater. 6, 1693 (1994)

R.D. Glover, J.M. Miller, J.E. Hutchison, ACS Nano 5, 8950 (2011)

N. Matsuhisa, D. Inoue, P. Zalar, H. Jin, Y. Matsuba, A. Itoh, T. Yokota, D. Hashizume, T. Someya, Nat. Mater. 16, 834 (2017)

P. Tavlarakis, J. Urban, N. Snow, J. Chromatogr. Sci. 49, 457 (2014)

J. Jiu, K. Murai, K. Kim, K. Suganuma, J. Mater. Sci. 21, 713 (2010)

Z. Zhang, B. Zhao, L. Hu, J. Solid State Chem. 110, 105 (1996)

J.J. Zhu, C.X. Kan, J.G. Wan, M. Han, G.H. Wang, J. Nanomater. 2011, 982547 (2011)

C. Kan, C. Wang, J. Zhu, H. Li, J. Solid State Chem. 183, 858 (2010)

S. Sakamoto, S. Nagao, K. Suganuma, J. Mater. Sci. 24, 2593 (2013)

K. Moon, H.A.I. Dong, R. Maric, S. Pothukuchi, A. Hunt, Y.I. Li, J. Electron. Mater. 34, 168 (2005)

Acknowledgements

The authors wish to thank Dr. J. Jiu (Senju Metal Industry, Co., Ltd.) for her instruction on polyol method and the members of the Comprehensive Analysis Center, ISIR, Osaka University for their help in XPS, ICP–AES, and TEM measurements. This work was partly supported both by JST ALCA Grant Number JPMJAL1610 Japan, and by “Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials” from the Ministry of Education, Culture, Sports, Science and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yeom, J., Zhang, H., Li, CF. et al. Fast and low-temperature sintering of Ag paste due to nanoparticles formed in situ. J Mater Sci: Mater Electron 30, 18080–18087 (2019). https://doi.org/10.1007/s10854-019-02161-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02161-8