Abstract

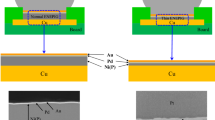

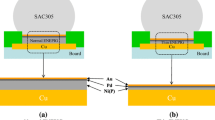

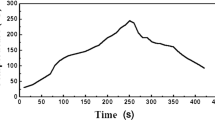

The effects of the thickness of the Ni layer in thin electroless-nickel electroless-palladium immersion gold (thin-ENEPIG) surface-finished printed circuit boards (PCB) with Sn-3.0Ag–0.5Cu (SAC305) solder joints during aging treatment were investigated. We evaluated the interfacial reactions and mechanical properties of 0.3–1.0 µm thick Ni layers in thin-ENEPIG PCBs with SAC305 solder joints at aging temperatures of 75, 100, 125, and 150 °C for 1000 h. A needle-type (Cu,aNi)6Sn5 intermetallic compound (IMC) layer formed at the interface of the SAC solder and Cu substrate. In addition, P-rich Ni layers were formed at the interface of the (Cu,Ni)6Sn5 IMC and Cu substrate for the 0.5–1.0 µm thick Ni joints. The thicknesses of the (Cu,Ni)6Sn5 IMCs with 0.3 and 0.5 µm Ni joints were strongly affected by the aging time and temperature. In contrast, the IMC growth rates of the 0.7 and 1.0 µm thick Ni joints were significantly lower than that of the 0.3 µm thick Ni joint. The reason for this behavior is that the P-rich Ni layer acts as a barrier for Sn and Cu diffusion at the joint and was maintained at the IMC/Cu interface after aging. In high-speed shear tests, the shear strengths of all Ni joints aged at 75 °C were similar. However, the rate of reduction in shear strength decreased with increasing Ni layer thickness as the aging time and temperature increased, but the shear strength of the 0.3 µm Ni joint rapidly decreased with increasing aging temperature and time. In contrast, the shear strengths of the 0.7 and 1.0 µm Ni joints slightly decreased with increasing aging temperature and time. The brittle fracture rates of the joints decreased with increasing Ni thickness, and we determined that this occurred because of the remaining P-rich Ni layer, which acts as a diffusion barrier during aging, at the interface of the 0.7 and 1.0 µm Ni joints. In low-speed shear tests, the shear strengths of the 0.7 and 1.0 µm Ni joints were slightly higher than those of the 0.3 and 0.5 µm Ni joints after aging at 125 and 150 °C for the entire aging period. Most fractures occurred via a ductile mode regardless of the Ni layer thickness. Therefore, a Ni layer thickness of more than 0.7 µm in thin-ENEPIG finished PCB with SAC305 solder joints is expected to yield high reliability on aging.

Similar content being viewed by others

References

Y.W. Yen, P.H. Tsai, Y.K. Fang, S.C. Lo, Y.P. Hsieh, C. Lee, J. Alloys. Compd. 503, 25 (2010)

K. Zeng, K.N. Tu, Mater. Sci. Eng., R 38, 55 (2002)

J. Keller, D. Baither, U. Wilke, G. Schmitz, Acta Mater. 59, 2731 (2011)

W.R. Myung, Y.I. Kim, S.B. Jung, J. Alloys. Compd. 615, s411 (2014)

M.I.I. Ramli, M.A.A. Mohd Salleh, F.A. Mohd Sobri, P. Narayanan, K. Sweatman, K. Nogita, J. Mater. Sci 30, 3669 (2019)

Y. Shi, Y. Yan, J. Liu, Z. Xia, Y. Lei, F. Guo, X. Li, J. Electron. Mater. 38, 1866 (2009)

X. Deng, G. Piotrowski, J.J. Williams, N. Chawla, J. Electron. Mater. 32, 1403 (2003)

S. Ahat, M. Sheng, L. Luo, J. Electron. Mater. 30, 1317 (2001)

L.R. Garcia, W.R. Osorio, A. Garcia, Mater. Des. 32, 4763 (2011)

T. R. Bieler, H. Jiang, L. P. Lehman, T. Kirkpatrick, E. J. Cotts, 2006 Electronic Components and Technology Conference, 1462

F. Gao, H. Nishikawa, T. Takemoto, J. Electron. Mater. 36, 1630 (2007)

Y. Zhang, Z. Cai, J. C. Suhling, P. Lall, M. J. Bozack, 2008 Electronic components and technology conference, 99 (2008)

K. Gain, Y.C. Chan, W.K.C. Yung, Microelectron. Reliab. 51, 975 (2011)

G. Chen, F. Wu, C. Liu, V.V. Silberschmidt, Y.C. Chan, J. Alloys. Compd. 656, 500 (2016)

M. Lu, D. Y. Shih, 47th annual international reliability physics symposium 2009, 149 (2009)

P. Liu, P. Yao, J. Liu, J. Alloys. Compd. 470, 188 (2009)

K. Gain, T. Fouzder, Y.C. Chan, W.K.C. Yung, J. Alloys. Compd. 509, 3319 (2011)

R. Zhang, F. Guo, J. Liu, H. Shen, F. Tai, J. Electron. Mater. 38, 241 (2009)

J.W. Yoon, B.I. Noh, Y.H. Lee, H.S. Lee, S.B. Jung, Microelectron. Reliab. 48, 1864 (2008)

J.W. Yoon, B.I. Noh, S.B. Jung, J. Electron. Mater. 40, 1950 (2011)

K. Zeng, R. Stierman, D. Abbott, M. Murtuza, in Thermal and thermomechanical proceedings 10th intersociety conference on phenomena in electronics systems in 2006 (IEEE), 1111, (2006)

J.W. Yoon, J.H. Bang, C.W. Lee, S.B. Jung, J. Alloys. Compd. 627, 276 (2015)

Y.M. Kim, J.Y. Park, Y.H. Kim, J. Electron. Mater. 41, 763 (2012)

T.T. Chou, C.J. Fleshman, H. Chen, J.G. Duh, J. Mater. Sci. 30, 2342 (2019)

J.W. Yoon, B.I. Noh, J.H. Yoon, H.B. Kang, S.B. Jung, J. Alloys. Compd. 509, L153 (2011)

C.F. Tseng, J.G. Duh, Mater. Sci. Eng., A 580, 169 (2013)

J. Kim, W.R. Myung, S.B. Jung, J. Electron. Mater. 45, 5895 (2016)

C.Y. Ho, J.G. Duh, Mater. Sci. Eng. A 611, 162 (2014)

J.W. Yoon, J.H. Back, S.B. Jung, J. Mater. Sci. 29, 4724 (2018)

C.E. Ho, S.J. Wang, C.W. Fan, W.H. Wu, J. Electron. Mater. 43, 16 (2014)

S.S. Ha, J.K. Jang, S.O. Ha, J.W. Kim, J.W. Yoon, B.W. Kim, S.K. Park, S.B. Jung, J. Electron. Mater. 38, 2489 (2009)

J. Wang, S. Xue, P. Zhang, P. Zhai, Y. Tao, J. Mater. Sci. 30, 9065 (2019)

X. Deng, R.S. Shidhu, P. Johnson, N. Chawla, Metall. Mater. Trans. A 36, 55 (2005)

J.H. Cho, J.W. Ahn, Y.E. Yoon, S.B. Shin, J. Jung, Mater. Sci. 23, 1515 (2012)

Acknowledgements

This work was supported by a research project grant from the Advanced Technology Center [Grant Number 10062737] from the Ministry of Trade, Industry and Energy, Republic of Korea.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, J., Back, JH., Jung, SB. et al. Effects of Ni layer thickness of thin-ENEPIG surface finishes on the interfacial reactions and shear strength of Sn-3.0Ag–0.5Cu solder joints during aging. J Mater Sci: Mater Electron 30, 12911–12923 (2019). https://doi.org/10.1007/s10854-019-01653-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01653-x