Abstract

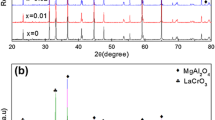

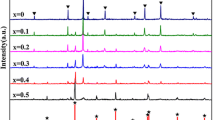

The effects of the sintering process on the microstructure and high temperature electrical properties of xMgAl2O4–(1 − x)LaCrO3 (x = 0.3, 0.4, 0.5) composite ceramics were investigated. X-ray diffraction (XRD) results show that all the composite ceramic samples are composed of the spinel oxide MgAl2O4 phase and orthogonal perovskite structure LaCrO3 phase, and no impurities appear. The grain size of the vacuum sintered ceramic is smaller, resulting in an increase in electrical resistance. X-ray photoelectron spectroscopy confirmed the presence of Cr3+ and Cr 4+ ions at the lattice sites. The EDS results show that the vacuum sintered ceramic has more Cr content due to the smaller oxygen partial pressure during vacuum sintering. The activation energy of the vacuum sintered sample is higher than the activation energy of the conventional sintered sample. All the composite ceramic samples have negative temperature coefficient characteristics and the resistivity increases with the increase of MgAl2O4 content.

Similar content being viewed by others

References

H. Yokokawa, N. Sakai, T. Kawada, M. Kokiya, J. Electron. Soc. 138, 1018 (1991)

O.I. Klyushnikov, V.V. Sal’nikov, N.M. Bogdanovich, J. Inorg. Mater. 38, 265 (2002)

T. Tachiwaki, Y. Kunifusa, M. Yoshinaka, K. Hirota, O. Yamaguchi, Mater. Sci. Eng. B 86, 255 (2001)

A. Feltz, J. Eur. Ceram. Soc. 20, 2367 (2000)

D. Houivet, J. Bernard, J.-M. Haussonne, J. Eur. Ceram. Soc. 24, 1237 (2004)

Y. Jiang, J. Gao, M. Liu, Y. Wang, G. Meng, Mater. Lett. 61, 1908 (2007)

I.-H. Jung, S. Decterov, A.D. Pelton, J. Am. Ceram. Soc. 88, 1921 (2005)

A.N. Kamlo, J. Bernard, C. Lelievre, D. Houivet, J. Eur. Ceram. Soc. 31, 1457 (2011)

A. Kumar, M.L. Singla, A. Kumar, J.K. Rajput, J. Mater. Sci.: Mater. Electron. 26, 1838 (2014)

Y. Luo, X. Liu, X. Li, J. Mater. Sci.: Mater. Electron. 17, 909 (2006)

J. Park, Ceram. Int. 41, 6386 (2015)

K. Park, J.K. Lee, J. Alloys Compd. 475, 513 (2009)

K. Park, J.K. Lee, S.J. Kim, W.S. Seo, W.S. Cho, C.W. Lee, S. Nahm, J. Alloys Compd. 467, 310 (2009)

K. Park, S.J. Yun, Mater. Lett. 58, 933 (2004)

B. Zhang, Q. Zhao, A. Chang, Y. Li, Y. Liu, Y. Wu, J. Eur. Ceram. Soc. 34, 2989 (2014)

B. Zhang, Q. Zhao, C. Zhao, A. Chang, J. Alloys Compd. 698, 1 (2017)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant No. 61671447), Tianshan Talent Project of Xinjiang Autonomous Region and the Scientific and Technological Talents Training Project of the Xinjiang Autonomous Region (Grant No. QN2016YX0161).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ga, A., Yin, X., Zhao, Q. et al. A study based on MgAl2O4–LaCrO3 composite ceramics for high temperature NTC thermistors. J Mater Sci: Mater Electron 30, 11117–11122 (2019). https://doi.org/10.1007/s10854-019-01454-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01454-2