Abstract

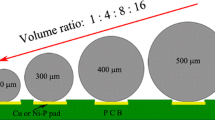

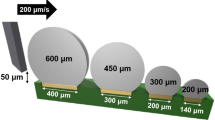

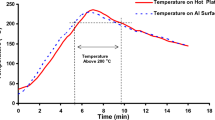

At present, electronic products are developing in the direction of miniaturization and integration, which leads to the downsizing of solder bump in the packaging process. Moreover, micro solder bumps often require undergoing multiple reflow processes due to the improvement of packaging technology, which has a great influence on interface reaction. Hence, it is necessary to study the effects of solder composition, bump size and reflow cycle on interfacial reaction between solder alloys and Cu substrates. In this experiment, Sn–xCu (x = 0, 0.7, 2.0 wt%) alloys with diameter of 200 µm, 500 µm, and 800 µm were soldered to Cu substrates at 250 °C for 1 min, and then reflowed 20 cycles totally. The size effect of micro solder joints on the growth of IMC after multiple reflows was analyzed. At the same time, the impact of Cu concentration inside the bulk solder on the interfacial reaction during multiple reflows was explored. This experiment finds that the diameter of IMC grains increases with the decrease of solder ball diameter after one reflow cycle, and a significant size effect occurs in Sn/Cu solder bump. As the number of reflow cycle increases, the size effect on interface reaction is more pronounced. The most direct kinetic factor of this phenomenon is that the average Cu concentration in the small-sized solder ball rises faster than the others. When the number of reflow cycle reach to nine times, the lateral growth rate of IMC grains begins to surpass the longitudinal growth rate, and the morphology of IMC grains becomes flat. This phenomenon is especially evident in the small-sized solder ball. Moreover, the addition of Cu element in solder promotes ripening reaction resulting in the lateral growth of IMC. Cu6Sn5 micro particles appearing at the Sn/Cu, Sn–0.7Cu/Cu interface hinder the grain boundary motion and inhibit the lateral annexation of IMC grains, thereby suppressing the lateral growth of IMC.

Similar content being viewed by others

References

A.S.M.A. Haseeb, Y.M. Leong, M.M. Arafat, Intermetallics 54, 86–94 (2014)

L. Liu, Z. Chen, C. Liu et al., Intermetallics 76, 10–17 (2016)

C.W. Chen, T.C. Chiu, Y.T. Chiu et al., Intermetallics 85, 117–124 (2017)

S.S. Ha, J.K. Jang, S.O. Ha et al., Microelectron. Eng. 87(3), 517–521 (2010)

J.H. Lau, Microelectron. Ind. 28(2), 8–22 (2011)

C.C. Chang, Y.W. Lin, Y.W. Wang et al., J. Alloys Compd. 492(1–2), 99–104 (2010)

H.T. Ma, H.R. Ma, A. Kunwar et al., J. Mater. Sci.: Mater. Electron. 29(1), 602–613 (2018)

W.K. Choi, H.M. Lee, J. Electron. Mater. 29(10), 1207–1213 (2000)

H. Ma, A. Kunwar, R. Huang et al., Intermetallics 90, 90–96 (2017)

L. Gu, L. Qu, H. Ma et al., ICEPT, 1–4 (2011). https://doi.org/10.1109/ICEPT.2011.6066848

H.K. Kim, K.N. Tu, Phys. Rev. B 53(23), 16027 (1996)

L. Qu, H.T. Ma, H.J. Zhao et al., Appl. Surf. Sci. 305(12), 133–138 (2014)

S. Li, Y. Du, L. Qu et al., ICEPT, 937–939 (2014)

M.L. Huang, F. Yang, N. Zhao et al., Mater. Lett. 139, 42–45 (2015)

L. Qu, N. Zhao, H.J. Zhao et al., Scripta Mater. 72–73(2), 43–46 (2014)

H. Ma, A. Kunwar, Z. Liu et al., J. Mater. Sci.: Mater Electron. 29(6), 4383–4390 (2018)

Y. Zhu, F. Sun, Solder. Surf. Mt. Technol. 29(2), 85–91 (2017)

C.M.L. Wu, M.L. Huang, J. Electron. Mater. 31(7), 828–828 (2002)

X.P. Li, J.M. Xia, M.B. Zhou et al., J. Electron. Mater. 40(12), 2425 (2011)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51871040 and 51571049) and “Research Fund for International Young Scientists” of National Natural Science Foundation of China (Grant No. 51750110504).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, R., Ma, H., Shang, S. et al. Size effect on interface reaction of Sn–xCu/Cu solder joints during multiple reflows. J Mater Sci: Mater Electron 30, 4359–4369 (2019). https://doi.org/10.1007/s10854-019-00758-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00758-7