Abstract

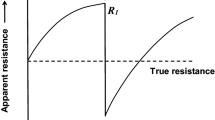

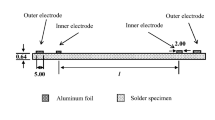

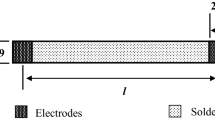

The performance and reliability of soldered joints are important for electronic packaging. This work provides the first observation of piezoelectricity (generating electric field and capacitance), piezoresistivity (changing the resistivity) and dielectricity (giving polarization) in solder. These effects influence electrical conduction. The solder may encounter stress (particularly thermal stress) during use in a soldered joint. The solder studied is the tin–lead eutectic alloy. The stress is tensile in the direction of electrical measurement. Although the piezoelectric coupling coefficient d33 of the solder (− (7.5 ± 0.8) × 10−6 pC/N) is very low compared to those of the well-known piezoelectric materials, the resulting electric field and capacitance are substantial and the changes are reversible upon unloading. The relative permittivity (2 kHz) (a dielectric material property) is very high ((3.973 ± 0.017) × 106) compared to those of conventional dielectric materials, but is comparable to those of previously reported steels. The polarization is due to the movement of the free electrons; it opposes the applied electric field. The permittivity increases reversibly with increasing tensile stress and is attributed to an unidentified reversible microstructural change. The permittivity increase contributes to d33 by only + (4.3 ± 0.6) × 10−7 pC/N, which is opposite in sign from the abovementioned overall negative d. The gage factor (fractional change in resistance per unit strain) associated with piezoresistivity is high (85 ± 6). The resistivity increases substantially and reversibly with increasing stress; it is attributed to the microstructural change and is disadvantageous for electrical conduction. However, the piezoelectricity and piezoresistivity enable the solder to sense its own condition (stress) without embedded or attached sensors.

Similar content being viewed by others

References

P. Lambracht, B. Kempf, M. Rettenmayr, Thermal fatigue resistance in Pb-based solder alloys for electronic packaging. Z. Metallkd. 93(2), 99–105 (2002)

X. Zhang, S.R. Lee, Y. Pao, A damage evolution model for thermal fatigue analysis of solder joints. J. Electron. Packag. 122(3), 200–206 (2000)

R.J. Coyle, K. Sweatman, B. Arfaei, Thermal fatigue evaluation of Pb-free solder joints: results, lessons learned, and future trends. JOM 67(10), 2394–2415 (2015)

R.J. Coyle, K. Sweatman, B. Arfaei, Erratum to: thermal fatigue evaluation of Pb-free solder joints: results, lessons learned, and future trends [Erratum to document cited in CA166:495209]. JOM 69(7), 1244 (2017)

Y. Chen, Y. Jin, R. Kang, Coupling damage and reliability modeling for creep and fatigue of solder joint. Microelectron. Reliab. 75, 233–238 (2017)

H. Schoeller, S. Bansal, A. Knobloch, D. Shaddock, J. Cho, Effect of alloying elements on the creep behavior of high Pb-based solders. Mater. Sci. Eng. A A528(3), 1063–1070 (2011)

K. Lee, J.W. Morris Jr., F. Hua, Influence of the substrate on the creep of SN solder joints. Metall. Mater. Trans. A 41A(7), 1805–1814 (2010)

R. Mahmudi, A.R. Geranmayeh, A comparative study of room-temperature creep in lead-free tin-based solder alloys. Int. J. Mater. Res. 101(2), 271–278 (2010)

L. Jiang, G. Zhang, J. Zhou, Size effects of lead-free solder joint thickness under shear creep based on micro-electrical-resistance strain, J. Phys. D 41(16), 165412/1–165412/6 (2008)

X.P. Zhang, L.M. Yin, C.B. Yu, Thermal creep and fracture behaviors of the lead-free Sn-Ag-Cu-Bi solder interconnections under different stress levels. J. Mater. Sci.: Mater. Electron. 19(4), 393–398 (2008)

K.D. Kim, D.D.L. Chung, Electrically conductive adhesive and soldered joints under compression. J. Adhes. Sci. Technol. 19(11), 1003–1023 (2005)

D.D.L. Chung, Functional Materials (World Sci. Pub., 2010), Ch. 2 and 3

M. Osterman, A. Dasgupta, Life expectancies of Pb-free SAC solder interconnects in electronic hardware. J. Mater. Sci.: Mater. Electron. 18(1–3), 229–236 (2007)

G. Gan, C. Du, C. Li, Design of lead-free solders and pollution control of lead. Adv. Mater. Res. (Durnten-Zurich, Switzerland) 881–883:1435–1438 (2014) (Chemical, Material and Metallurgical Engineering III)

D.D.L. Chung, K. Shi, Sensing the stress in steel by capacitance measurement. Sens. Actuators A 274, 244–251 (2018)

E. Sentuerk, M. Okutan, S.E. San, O. Koeysal, Debye type dielectric relaxation in carbon nano-balls’ and 4-DMAABCA acid doped E7 coded nematic liquid crystal. J Non-Cryst. Solids 354(30), 3525–3528 (2008)

P. Xie, W. Sun, Y. Liu, A. Du, Z. Zhang, G. Wu, R. Fan, Carbon aerogels towards new candidates for double negative metamaterials of low density. Carbon 129, 598–606 (2018)

P. Xie, Z. Zhang, K. Liu, L. Qian, F. Dang, Y. Liu, R. Fan, X. Wang, S. Dou, C/SiO2 meta-composite: overcoming the λ/a relationship limitation in metamaterials. Carbon 125, 1–8 (2017)

https://xdevs.com/doc/Keithley/2002/SPEC-2002.pdf. Accessed 22 Sept 2018

http://www.matweb.com/search/datasheet.aspx?matguid=3a5c8bc670914d588b26ab0b994d88cb&ckck=1. Accessed 23 Dec 2018

S. Mallik, E.H.L. Chan, N. Ekere, Nonlinear viscoelastic characteristics of Sn-Ag-Cu solder pastes used in electronics assembly applications. J. Mater. Eng. Perform. 22(4), 1186–1193 (2013)

T. Tian, K. Chen, M. Kunz, N. Tamura, C. Zhan, T. Chang, K. Tu, Preferred orientation of 30 µm fine pitch Sn2.5Ag micro-bumps studied by synchrotron polychromatic X-ray Laue microdiffraction, in IEEE Electronic Components and Technology Conference, vol. 62nd, pp. 882–885 (2012)

S. Yang, Y. Tian, C. Wang, Investigation on Sn grain number and crystal orientation in the Sn-Ag-Cu/Cu solder joints of different sizes. J. Mater. Sci.: Mater. Electron. 21(11), 1174–1180 (2010)

M.F. Galikhanov, Influence of electret state of two-layer polymer materials on their adhesion to metal substrates. Int. J. Adhes. Adhes. 86, 1–3 (2018)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xi, X., Chung, D.D.L. Piezoelectricity, piezoresistivity and dielectricity discovered in solder. J Mater Sci: Mater Electron 30, 4462–4472 (2019). https://doi.org/10.1007/s10854-019-00735-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00735-0