Abstract

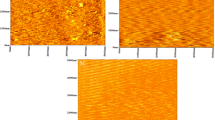

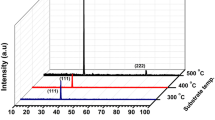

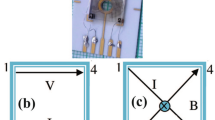

Titanium nitride (TiN) thin films have been prepared by direct-current reaction magnetron sputtering technique on different substrates (glass and Si) and the influence of substrate and Ar/N2 gas flow ratio on structural, optical and electrical properties of TiN thin films were discussed. X-ray diffraction suggested that with the ratio of Ar/N2 decreasing, the diffraction intensity of (111) plane gradually diminished while (200) plane increased and films on Si substrate exhibited better crystalline quality than glass substrate. Improvement of Ar/N2 ratio is contribute to enhance the deposition rate and the obvious surface roughness were observed when the ratio up to 49. Photoluminescence spectra showed that TiN films on Si substrate showed higher intrinsic emission and lower defect emission. Moreover, the resistivity of TiN films showed obviously decreasing as the flow rate ratio of Ar/N2 increased, especially films on Si substrate.

Similar content being viewed by others

References

G. Martinez, V. Shutthanandan, J.F. Chessa, C.V. Ramana, Ceram. Int. 40, 5757–5764 (2014)

E. Ajenifuja, G.A. Osinkolu, A.Y. Fasasi, D.A. Pelemo, J. Mater. Sci. 27, 1–7 (2016)

H.H. Huanga, M.H. Hona, M.C. Wang, J. Cryst. Growth 240, 513–520 (2002)

S. Kadlec, J. Musil, J. Vyskcil, Surf. Coat. Technol. 54, 287–296 (1992)

F. Jiang, T.F. Zhang, B.H. Wu, Surf. Coat. Technol. 292, 54–62 (2016)

S. Niyomsoan, W. Grant, D.L. Olson, B. Mishra, Thin Solid Films 415, 187–194 (2002)

B. Subramanian, R. Ananthakumar, V.S. Vidhya, Mater. Sci. Eng. B 176, 1–7 (2011)

A. Kavitha, R. Kannan, P.S. Reddy, S. Rajashabala, J. Mater. Sci. 27, 10427–10434 (2016)

D.M. Devia, E. Restrepo-Parra, P.J. Arango, A.P. Tschiptschin, J.M. Velez, Appl. Surf. Sci. 258, 1164–1174 (2011)

D.R. Irala, L.C. Fontana, J.C. Sagas, H.S. Maciel, Surf. Coat. Technol. 240, 154–159 (2014)

A. Kavitha, R. Kannan, S. Rajashabala, J. Mater. Sci. 27, 10427–10434 (2016)

N. Ghobadi, M. Ganji, C. Luna, A. Arman, J. Mater. Sci. 27, 1–9 (2015)

J. Lu, N. Arshi, J. Min. Met. Mater. Sci. 68, 1634–1639 (2016)

A. Kavitha, R. Kannan, K.R. Gunasekhar, J. Electron. Mater. 7, 1–8 (2017)

M. Brizuela, P. Corengia, R. Munoz, Plasma Process. Polym. 6, S162–S167 (2009)

P.E. Hovsepian, A.A. Sugumaran, Y. Purandare, Thin Solid Films 562, 132–139 (2014)

M.N. Solovan, V.V. Brus, P.D. Maryanchuk, I.M. Fodchuk, Opt. Spectrosc. 117, 753–755 (2014)

M.I. Jones, I.R. McColl, D.M. Grant, Surf. Coat. Technol. 132, 143–151 (2000)

S.G. Lu, Y.H. Lu, Z.K. Xu, J. Am. Ceram. Soc. 90, 4002–4004 (2007)

S. Strite, J. Ruan, Z. Li, A. Salvador, H. Chen, D.J. Smith, W.J. Choyke, J. Vac. Sci. Technol. B 9, 1924–1929 (1991)

D. Volm, K. Oettinger, T. Streibl, D. Kovalev, J. Diener, J. Majewski, L. Eckey, Phys. Rev. B 53, 16543–16550 (1996)

P.P. Paskov, R. Schifano, B. Monemar, T. Paskova, S. Figge, J. Appl. Phys. 98, 093519–093526 (2005)

X. Lin, G. Zhao, G. Duan, G. Han, J. Alloys Compd. 502, 195–198 (2010)

N.K. Ponon, D.J. Appleby, E. Arac, P.J. King, S. Ganti, K.S. Kwa, Thin Solid Films 578, 31–37 (2015)

J.H. Huang, K.W. Lau, G.P. Yu, Surf. Coat. Technol. 191, 17–24 (2005)

Acknowledgements

This work was supported by Natural Science Foundation of China (NSFC) No. 11675029 and Sichuan Province Science and Technology Program No. 2015GZ0194 and No. 2016FZ0018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Rights and permissions

About this article

Cite this article

Gu, P., Zhu, X., Li, J. et al. Influence of substrate and Ar/N2 gas flow ratio on structural, optical and electrical properties of TiN thin films synthetized by DC magnetron sputtering. J Mater Sci: Mater Electron 29, 9893–9900 (2018). https://doi.org/10.1007/s10854-018-9031-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9031-2