Abstract

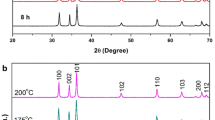

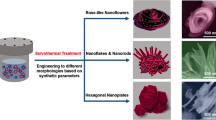

ZnS nanoparticles were synthesized by hydrothermal method. The influences of reaction temperature, holding time and S/Zn molar ratio on the structure, morphology, optical and electrical properties of ZnS nanoparticles were studied systematically at the range of 90 °C to 180 °C, 6 h to 15 h and 1:2 to 2.5:1, respectively. The results indicate that the reaction temperature, holding time and S/Zn molar ratio have no influence on phase structure. All the samples belong to zinc blende cubic structure of ZnS. However, the reaction temperature has strong influences on the growth of crystals, optical and electrical properties due to LaMer theory and two-stage growth kinetics. When the reaction temperature increases from 90 °C to 180 °C, the crystallite sizes increase from 7.0 nm to 9.7 nm and the average particle sizes decrease from 21 nm to 14 nm; the emission peaks are red shifted from 445 nm to 460 nm and the emission intensity is increased by 4.4 times; the dielectric constant and dielectric loss decrease from 4.86 to 4.71 and 2.86 × 104 to 2.70 × 104, respectively. While, the holding time has slight influences on the growth of crystals, optical and electrical properties. And the emission band and emission intensity of ZnS nanoparticles can be adjusted by the S/Zn molar ratio. When the S/Zn molar ratio is less than 1:1 or equal to 1:1, the emission bands range from 400 nm to 600 nm centered at ~ 450 nm. When the S/Zn molar ratio is greater than 1:1, the emission bands range from 400 nm to 700 nm centered at ~ 540 nm.

Similar content being viewed by others

References

H. Jeong, H.M. Oh, S. Bang et al., Nano Lett. 16, 1858 (2016)

A. Martí, N. López, E. Antolín et al., Thin Solid Films 511–512, 638 (2006)

M.R. Hoffmann, W.Y. Choi, D.W. Bahnemann, Chem. Rev. 95, 69 (1995)

S. Zinatloo-Ajabshir, M. Salavati-Niasari, A. Sobhani, Z. Zinatloo-Ajabshir, J. Alloys Compd. 767, 1164 (2018)

X. Wu, H. Liu, J. Liu et al., Nat. Biotechnol. 21, 41 (2003)

S. Shinohara, A. Mochizuki, H. Yoshida, M. Sumi, Appl. Opt. 25, 1417 (1986)

M.C. Divyasree, K. Chandrasekharan, Opt. Mater. 67, 119 (2017)

K. Qiu, D. Qiu, L. Cai et al., Mater. Lett. 198, 23 (2017)

Y. Zhao, Y. Zhang, G. Qin et al., Int. J. Nanomed. 12, 1927 (2017)

V.G. Bessergenev, E.N. Ivanova, Y.A. Kovalevskaya et al., Mater. Res. Bull. 30, 1393 (1995)

N. Bansal, G.C. Mohanta, K. Singh, Ceram. Int. 43, 7193 (2017)

W. Zhao, Z. Wei, L. Zhang, X. Wu, X. Wang, J. Jiang, J. Nanomater. (2017), 7(1), 22

P.V. Ben, B.H. Van, VNU J. Sci. Math. Phys. 33, 81 (2017)

S.K. Panda, S. Chaudhuri, J. Colloid Interface Sci. 313, 338 (2007)

F. Davar, M. Mohammadikish, M.R. Loghman-Estarki, Z. Hamidi, CrystEngComm 14, 7338 (2012)

Z. Ren, H. Yang, L. Shen, S.D. Han, J. Mater. Sci. Mater. Electron. 19, 1 (2008)

T.I. Chanu, D. Samanta, A. Tiwari, S. Chatterjee, Appl. Surf. Sci. 391, 548 (2016)

G.O. Siqueira, T. Matencio, S.H. Da et al., Phys. Chem. Chem. Phys. 15, 6796 (2013)

L. Zhang, L. Yang, Cryst. Res. Technol. 43, 1022 (2010)

X. Yu, L.Y. Cao, J.F. Huang, L. Jia, F. Jie, C.Y. Yao, J. Alloys Compd. 549, 1 (2013)

N. Arbi, I.B. Assaker, M. Gannouni, A. Kriaa, R. Chtourou, Mater. Sci. Semicond. Process. 40, 873 (2015)

H. Qu, L. Cao, G. Su, W. Liu, Y. Sun, B. Dong, Adv. Mater. Res. 79–82, 589 (2009)

T.T.Q. Hoa, N.D. The, S. Mcvitie et al., Opt. Mater. 33, 308 (2011)

S. Kumar, N.K. Verma, J. Mater. Sci. Mater. Electron. 25, 785 (2014)

L. Liu, L. Yang, Y. Pu, D. Xiao, J. Zhu Mater. Lett. 66, 121 (2012)

F. Beshkar, S. Zinatlooajabshir, S. Bagheri, M. Salavatiniasari, PLoS ONE 12, e0158549 (2017)

Z.Q. Li, J.H. Shi, Q.Q. Liu, Z.A. Wang, Z. Sun, S.M. Huang, Appl. Surf. Sci. 257, 122 (2010)

B.D. Cullity, Am. J. Phys. 25, 50 (1957)

X. Zhou, Q. Yang, H. Wang, F. Huang, J. Zhang, S. Xu, Adv. Powder Technol. 29, 977 (2018)

A.S. Kabalnov, E.D. Shchukin, Adv. Colloid Interface 38, 69 (1992)

T. Zargar, A. Kermanpur, Ceram. Int. 43, 5794 (2017)

S. Zinatloo-Ajabshir, M.S. Morassaei, M. Salavati-Niasari, J. Clean Prod. 198, 11 (2018)

M.B. Mohamed, K.Z.I. †, A.Stephan Link, M.A. Elsayed, J. Phys. Chem. B 102, 9370 (1998)

V.K. Lamer, R.H. Dinegar, J. Am. Chem. Soc. 72, 4847 (1950)

R. Sahraei, S. Darafarin, J. Lumin. 149, 170 (2014)

G. Murugadoss, J. Lumin. 132, 2043 (2012)

T.Q.H. Tran, L. Van Vu, T.D. Canh, N.N. Long, J. Phys. Conf. Ser. (2009) p. 012081

J. Liu, J. Ma, Y. Liu et al., J. Alloys Compd. 486, L40 (2009)

Z. Li, J. Wang, X. Xu, X. Ye, Mater. Lett. 62, 3862 (2008)

P. Iranmanesh, S. Saeednia, N. Khorasanipoor, Mater. Sci. Semicond. Process. 68, 193 (2017)

Acknowledgements

This work was financially supported by the project of Natural Science Foundation Zhejiang Provincial (LY15F050005 and LZ14B010001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhou, X., Yang, Q., Wang, H. et al. Influences of reaction temperature, holding time and S/Zn molar ratio on structure, morphology, optical and electrical properties of ZnS nanoparticles synthesized by hydrothermal method. J Mater Sci: Mater Electron 30, 1089–1099 (2019). https://doi.org/10.1007/s10854-018-0378-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0378-1