Abstract

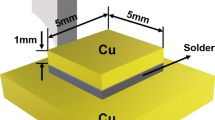

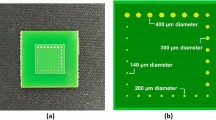

A reduction of the particle size used in solder pastes was shown to affect the electrical and mechanical properties of finely printed solder bumps. Sn–3.0Ag–0.5Cu solder nanoparticles were synthesized using a radio frequency thermal plasma system, and solder pastes were formulated for reverse-offset printing of solder bump arrays with a size of 30 µm. As the nanoparticle ratio in the paste increased, the degree of supercooling, ΔT, increased with a separation of the exothermic peaks for the solidification of β-Sn and the precipitation of intermetallic compounds (IMCs). The networks of finely precipitated IMCs formed at the boundaries of large β-Sn increased the shear strength to 73 MPa. However, insufficient flux deteriorated the electrical and mechanical properties because it delayed the solidification of primary β-Sn as well as the melting of the solder. As a result, the Sn–3.0Ag–0.5Cu solder paste containing a nanoparticle ratio of 25% exhibited an optimum printability for reverse-offset printing of solder bumps, and the resulting bumps had an electrical conductance of 0.4 mΩ and a shear strength of 73 MPa.

Similar content being viewed by others

References

K.J. Puttlitz, G.T. Galyon, J. Mater. Sci. Mater. Med. 18, 347–365 (2007)

L.R. Garcia, W.R. Osório, L.C. Peixoto, A. Garcia, Mater. Charact. 61, 212–220 (2010)

J. Keller, D. Baither, U. Wilke, G. Schmitz, Acta. Mater. 59, 2731–2741 (2011)

D. Li, C. Liu, P.P. Conway, J. Electron. Mater. 35, 388–398 (2006)

R.R. Chromik, R.P. Vinci, S.L. Allen, M.R. Notis, Jom. 55, 66–69 (2003)

Y. Takamatsu, H. Esaka, K. Shinozuka, Mater. Trans. 52, 189–195 (2011)

K.S. Kim, S.H. Huh, K. Suganuma, J. Alloys Compd. 352, 226–236 (2003)

S.L. Tay, A.S.M.A. Haseeb, M. Rafie Johan, Solder. Surf. Mount Technol. 23, 10–14 (2011)

H. Zhang, Q.S. Zhu, Z.Q. Liu, L. Zhang, H. Guo, C.M. Lai, J. Mater. Sci. Technol. 30, 928–933 (2014)

P. Yao, P. Liu, J. Liu, J. Alloys Compd. 462, 73–79 (2008)

S.K. Kang, D.Y. Shih, D. Leonard, D.W. Henderson, T. Gosselin, S.I. Cho, W.K. Choi, Jom. 56, 34 (2004)

D. Lin, G.X. Wang, T.S. Srivatsan, M. Al-Hajri, M. Petraroli, Mater. Lett. 53, 333–338 (2002)

G.Y. Li, X.Q. Shi, Trans. Nonferrous Metals Soc. China 16, 739–743 (2006)

J.X. Wang, S.B. Xue, Z.J. Han, S.L. Yu, Y. Chen, Y.P. Shi, H. Wang, J. Alloys Compd. 467, 219–226 (2009)

P. Liu, P. Yao, J. Liu, J. Electron. Ma. 37, 874–879 (2008)

A.K. Gain, Y.C. Chan, W.K. Yung, Microelectron. Reliab. 51, 975–984 (2011)

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, C.H. Huang, Mater. Des. 31, 4831–4835 (2010)

S. Chellvarajoo, M.Z. Abdullah, Mater. Des. 90, 499–507 (2016)

X.D. Liu, Y.D. Han, H.Y. Jing, J. Wei, L.Y. Xu, Mater. Sci. Eng. A. Struct. Mater. 562, 25–32 (2013)

J.H. Lau, J. Electron. Packag. 138, 1–23 (2016)

S.K. Kang, P. Gruber, D.Y. Shih, Jom 60, 66–70 (2008)

X. Liu, S. Xu, G.Q. Lu, D.A. Dillard, Microelectron. Reliab. 41, 1979–1992 (2001)

H. Hwang, S.M. Hong, J.P. Jung, C.S. Kang, Solder. Surf. Mount Technol. 15(2), 10–16 (2003)

L.C. Yung, C.C. Fei, J.S. Mandeep, H.B. Abdullah, L.K. Wee, PloS. One. 9(5), 97484 (2014)

E.H. Amalu, N.N. Ekere, S. Mallik, Mater. Des. 32, 3189–3197 (2011)

T.M. Lee, H.S. Han, B. Kim, S.W. Kwak, J.H. Noh, I. Kim, Thin solid films 548, 566–571 (2013)

Y.M. Choi, E.S. Lee, T.M. Lee, K.Y. Kim, Microelectron. Eng. 134, 1–6 (2015)

Y. Gao, C. Zou, B. Yang, Q. Zhai, J. Liu, E. Zhuravlev, C. Schick, J. Alloys Compd. 484, 777–781 (2009)

C. Andersson, C. Zou, B. Yang, Y. Gao, J. Liu, Q. Zhai, In Electronics System-Integration Technology Conference. 2, pp. 915–922 (2008)

J. Szépvölgyi, I. Mohai, Z. Károly, L. Gál, J. Eur. Ceram. Soc. 28, 895–899 (2008)

M.J. Son, M. Kim, T.M. Lee, J. Kim, H.J. Lee, I. Kim, J. Mater. Process. Technol. 259, 126–133 (2018)

Acknowledgements

This research was supported by the Technology Innovation Program (10080746) of the Ministry of Trade, Industry & Energy (MOTIE, Korea), and the R&D Convergence Program of the National Research Council for Science and Technology for the Republic of Korea (CAP-15-04-KITECH).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Son, MJ., Jeong, J.W., Kim, H. et al. Effect of particle size distribution on the mechanical and electrical properties of reverse-offset printed Sn–Ag–Cu solder bumps. J Mater Sci: Mater Electron 29, 19620–19631 (2018). https://doi.org/10.1007/s10854-018-0021-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0021-1