Abstract

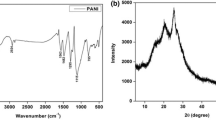

In this work, an effort has been made to develop a new type of complex conductive adhesive filled with silver decorated multi-walled carbon nanotubes (Ag-MWCNT). MWCNTs have been modified using N,N-dimethyl formamide (DMF) as a reducing agent and silver nanoparticles (Ag-NPs) has been homogeneously decorated against the surface. Fourier transform infra-red spectroscopy (FTIR) and Raman spectroscopy concluded that carboxylic groups were anchored to the surface of nanotubes. X-ray diffraction (XRD), transmission electron microscopy (TEM) and energy-dispersive spectroscopy (EDS) confirmed that Ag-NPs were formed and uniformly deposited onto the surface of carboxylic functionalized MWCNT. Test results indicated an improvement in the thermal conductivity up to 0.88 W/mK, which was about four-fold increase over pristine epoxy. The curing kinetics of Ag-MWCNTs reinforced epoxy adhesive system was also studied using non-isothermal differential scanning calorimetric (DSC) technique. The activation energy obtained by Kissinger’s method was reduced from 57.2 to 54 kJ/mol with an addition of 0.5 wt% of Ag-MWCNT within unmodified epoxy. Lap shear strength of the adhesive containing 0.5 wt% of Ag-MWCNT was higher than the pristine polymer thus confirming reinforcing effect of Ag-MWCNT in conductivity applications.

Similar content being viewed by others

References

L. Chen, P. Zhao, H. Xie, W. Yu, Compos. Sci. Technol 125, 17 (2016)

F.L. Guan, CX. Gui, HBin Zhang, ZG. Jiang, Y. Jiang, Z.Z. Yu, Composites B 98, 134 (2016)

A. Larmagnac, S. Eggenberger, H. Janossy, J. Voros, Sci. Rep. 4, 7254 (2014)

T.M. Cornsweet, Science 168, 433 (1970)

M.J. Hanus, A.T. Harris, Prog. Mater. Sci. 58, 1056 (2013)

V. Causin, C. Marega, A. Marigo, G. Ferrara, A. Ferraro, Eur. Polym. J. 42, 3153 (2006)

S. Yu, P. Hing, X. Hu, Science 33, 289 (2002)

C.V. Bouanga, T.F. Heid, M.F. Frechette, E. David, Elecrical Insul. Dielectr. Phenom. ,709 (2015) doi:10.1109/CEIDP.2015.7352138

H. Ishida S. Rimdusit, Thermochim. Acta 320, 177 (1998)

E.S. Choi, J.S. Brooks, D.L. Eaton, M.S. Al-Haik, M.Y. Hussaini, H. Garmestani, D. Li, K. Dahmen, J. Appl. Phys 94, 6034 (2003)

E. Fortunati, F.D. Angelo, S. Martino, A. Orlacchio, J.M. Kenny, I. Armentano, Carbon. (2011). doi:10.1016/j.carbon.2011.02.004

Y.X. Fu, Z.X. He, D.C. Mo, S.S. Lu, Int. J. Therm. Sci 86, 276 (2014)

N.K. Mahanta, M.R. Loos, I. Manas Zlocozower, A.R. Abramson, J. Mater. Res. 30, 959 (2015)

T. Huang, X. Zeng, Y. Yao, R. Sun, F. Meng, J. Xu, C. Wong, RSC Adv. (2016) doi:10.1039/C5RA27315C

P. Kim, L. Shi, A. Majumdar, P.L. McEuen, Phys. Rev. Lett. 87, 215502 (2001)

S.Y. Yang, C.C.M. Ma, C.C. Teng, Y.W. Huang, S.H. Liao, Y.L. Huang, H.W. Tien, T.M. Lee, K.C. Chiou, Carbon 43, 592 (2010). doi:10.1016/j.carbon.2009.08.047

F. Xin, L. Li, Composites A 42, 961 (2011)

H. Huang, C. Liu, Y. Wu, S. Fan. Adv. Mater. 17, 1652 (2005)

N. Alexeyeva, J. Kozlova, V. Sammelselg, P. Ritslaid, H. Mandar, K. Tammeveski, Appl. Surf. Sci. 256, 3040 (2010)

Q. Liu, W. Ren, Z.G. Chen, B. Liu, B. Yu, F. Li, H. Cong, H.M. Cheng, Carbon 2, 1722 (2008). doi:10.1016/j.carbon.2008.06.021

F. Ahmadpoor, S.M. Zebarjad, K. Janghorban, Mater. Chem. Phys. 139, 113 (2013)

P.C. Ma, B.Z. Tang, J.K. Kim, Carbon 46,1497 (2008). doi:10.1016/j.carbon.2008.06.048

B. Munkhbayar, M.R. Tanshen, J. Jeoun, H. Chung, H. Jeong, Ceram. Int. 39, 6415 (2013)

R. Gulotty, M. Castellino, P. Jagdale, A. Tagliaferro, A.A. Balandin, ACS Nano 7, 5114 (2013)

M.A. Vargas, H. Vazquez, G. Guthausen, Thermochim. Acta 611, 10 (2015)

J. Hu, J. Shan, J. Zhao, Z. Tong, Thermochim. Acta 632, 56 (2016)

S. Montserrat, J. Malek, Thermochim. Acta 228, 47 (1993)

W. Fang, X. Jun, W. Jing-wen, L. Shu-qin, High Perform. Polym. 24, 730 (2012)

T. Zhou, X. Wang, X. Liu, D. Xiong, Carbon 48, 1171 (2009). doi:10.1016/j.carbon.2008.12.039

S.-Y. Lee, S.J. Park, Bull. Korean Chem. Soc. 31, 1596 (2010)

S. Chen, W. Shen, G. Wu, D. Chen, M. Jiang, Chem. Phys. Lett. 402, 312 (2005)

R. Yudianti, H. Onggo, Y. Saito, T. Iwata, J. Azuma, Open Mater. Sci. J. 5, 242 (2011)

M.A. Atieh, O.Y. Bakather, B. Al-Tawbini, A. A. Bukhari, F.A. Abuilaiwi, M.B. Fettouhi, Bioinorg. Chem. Appl. 2010, (2010)

G. Grassi, A. Scala, D. Iannazzo, A. Piperno, Chem. Commun. 48, 6836 (2012)

S.H. Pisal, N.S. Harale, T.S. Bhat, H. Dshmukh, P.S. Patil, IOSR J. Appl. Chem. 7, 49 (2014)

T.W. Ebbeser, H. Hiura, M.E. Bisher, M.M.J. Treacy, J.L. Shreeve-keyer, R.C. Haushalter, adv. mater. 8, 155 (1996) doi:10.1002/adma.19960080212

Q. Li, Q.Z. Xue, X.L. Gao, Q.B. Zheng, Express. Polym. Lett. 3, 769 (2009)

N. Jahan, A.T. Narteh, M. Hosur, M. Rahman, S. Jeelani, Open J. Compos. Mater. 3, 40 (2013)

L.J. Cui, Y. Bin Wang, W.J. Xiu, W.Y. Wang, L.H. Xu, X.B. Xu, Y. Meng, L.Y. Li, J. Gao, L.T. Chen, H.Z. Geng, Mater. Des. 49, 279 (2013)

S.K. Sahoo, S. Mohanty, S.K. Nayak, Thermochim. Acta. 614, 163 (2015)

M.T. Le S.C. Huang, Materials. 8, 5526 (2015)

F.H. Gojny, K. Schulte, Compos. Sci. Technol. 64, 2303 (2004)

G.V. Ramana, B. Padya, R.N. Kumar, K.V. Prabhakar, P.K. Jain, Indian J. Eng. Mat. Sci. 17, 331 (2010)

P. Jojibabu, M. Jagannatham, P. Haridoss, G.D. Janaki Ram, A.P. Deshpande, S.R. Bakshi, Composites A 82, 53 (2016)

Acknowledgements

This work is supported by Board of Research in Nuclear Sciences-BRNS (Grant No. 39/11/2015-BRNS), Department of Atomic Energy (DAE), Govt. of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.K., Panda, B.P., Mohanty, S. et al. Study on metal decorated oxidized multiwalled carbon nanotube (MWCNT) - epoxy adhesive for thermal conductivity applications. J Mater Sci: Mater Electron 28, 8908–8920 (2017). https://doi.org/10.1007/s10854-017-6621-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6621-3