Abstract

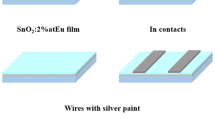

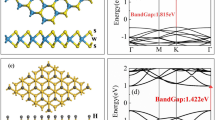

Electrical and optical properties of heterojunction composed of GaAs and SnO2 are presented. SnO2 thin film was deposited by sol-gel-dip-coating and doped with Ce3+ whereas the GaAs layer was deposited by resistive evaporation or sputtering. The purpose of this investigation is to combine the blue emission properties of the rare-earth with the unique transport properties generated by the heterojunction assembly. We have found that illumination with light of energy above the GaAs bandgap and below the SnO2 bandgap decrease drastically the GaAs/SnO2 heterojunction resistance. Under this condition, the sample exhibits an unusual behavior: the conductivity is practically temperature independent. This behavior was related with the presence of interface conduction, which could be associated to a two-dimensional electron gas at the GaAs/SnO2 interface. This feature takes places only for the sample where the GaAs bottom layer is deposited by sputtering, which presents a smoother surface as inferred by AFM images. The deposition sequence of the layers is fundamental to provide sample excitation which strongly contributes to the sample conductivity. Energies above the SnO2 bandgap only excite the top oxide layer. When the GaAs is the top layer it acts as a shield, and only effects from the ions located close to the interface SnO2/GaAs are observed. Luminescence from the Ce3+ ion can be detected, but overlap with emission from the matrix. Results suggest that a more organized GaAs bottom layer may contribute for a more efficient emission and also for signal separation.

Similar content being viewed by others

References

M. Ishii, S. Komuro, T. Morikawa, J. Appl. Phys. 94(6), 3823–3827 (2003)

S.C. Ray, M.K. Karanjai, D. Dasgupta, Surf. Coat. Technol 102(1), 73–80 (1998)

E. Dien, J.M. Laurent, A. Smith, J Eur. Ceram. Soc 19(6–7), 787–789 (1999)

H. Peng, H. Song, B. Chen, J. Wang, S. Lu, X. Kong, J. Zhang, J. Chem. Phys. 118(7), 3277–3282 (2003)

X. Yang, M.J. Jurkovic, J.B. Heroux, W.I. Wang Appl. Phys. Lett. 75(2),178–180 (1999).

S.M. Sze, Physics of Semiconductor Devices (Wiley, New York, 1985)

T. F. Pineiz, L. V.A. Scalvi, M.J. Saeki and E. A. Morais, J. Electron. Mat. 39(8), 1170–1176 (2010).

T.F. Pineiz, E.A. de Morais, L.V.A. Scalvi, C.F. Bueno, Appl. Surf. Sci. 267, 200–205 (2013)

C.F. Bueno, L.V.A. Scalvi, M.S. Li, M. J. Saeki, Opt. Mater. Express 5 59–72 (2015).

G. Du, Y. Cui, X.C. Xia, X.P. Li, H.C. Zhu, B.L. Zhang, Y.T. Zhang, Y. Ma Y, Appl. Phys. Lett. 90(24), 243504–243506 (2007)

M. Soylu, A.A. Al-Ghamdi, O.A. Al-Hartomy, F. El-Tantawyd, F. Yakuphanoglu, Physica E Low Dimens. Syst. Nanostruct. 64, 240–245 (2014).

S.T. Tan, J.L. Zhao, S. Iwan, X.W. Su, X. Tang, J. Ye, M. Bosman, L.J. Tang, G.Q. Lo, K.L. Teo IEEE Trans. On Electron. Dev. 57(1):129–233 (2010).

E. Cuculescu, I. Evtodiev, M. Caraman, Thin Solid Films 517(7), 2515–2518 (2009)

S. Vatavu, H. Zhao, I. Caraman, P. Gasin, C. Ferekides, Thin Solid Films 519(21), 7176–7179 (2011)

J.L.B Maciel Jr, E.A. Floriano, L.V.A. Scalvi, L.P. Ravaro, J Mater Sci 46, 6627–6632 (2011)

M.H. Boratto, L.V.A. Scalvi, Ceram. Int. 40, 3785–3791(2014)

M.H. Boratto, L.V.A. Scalvi, J.L.B. Maciel Jr, M.J. Saeki, E.A. Floriano, Mater. Res. 17(6), 1420–1426 (2014)

P. Dorenbos Phys. Rev. B Condens. Matter Mater. Phys. 64, 125117 (2001).

K. Annapurna, R.N. Dwivedi, P. Kundu, S. Buddhydu, Mater. Lett. 58, 787 (2004)

H. Zhang, X. Fu, S. Niu, G. Sun, Q. Xin, J. Lumin. 115, 7 (2005)

F. Gu, S.F. Wang, M.K. Lu, Y.X. Qi, G.J. Zhou, J. Cryst. Growth 255, 357 (2003)

F. Gu, S.F. Wang, M.K. Lu, Y.X. Qi, Opt. Mater. 25, 59 (2004)

Y. Yang, L. Liu, M. Li, C. Mi, Y. Liu, X. Su, J. Zhang, X. Li, F. Yu, S. Cai. Sci. Adv. Mater. 7(7), 1304–1309 (2015)

Z. Mao, Y. Zhu, Y. Wang, L. Gan, J. Mater. Sci. 49(13), 4439–4444 (2014)

K. Horn., in Electronic Structure of Semiconductor Surfaces, ed by K. Horn, M. Scheffler. Handbook of Surface Science, vol 2. (Elsevier, Amsterdam, 2000), p. 385–431.

D.C. Tsui, Phys. Rev., 24, 303–305 (1970)

C.W. Bark, P. Sharma, Y. Wang, S.H. Beak, S. Lee, S. Ryu, Nano Lett. 12, 1765–1771 (2012)

Y. Wang, M.K. Niranjan, S.S. Jaswal, E.Y. Tsymbal, Phys. Rev. B 80, 165130-1-10 (2009)

E.Y. Wang, R.N. Legge, IEEE Trans. Electron Dev. 25(7), 800–803 (1978)

G.D. Azevedo, J. H. D. Silva, E. Avendano, Nucl. Instr. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 238 (1–4), 329–333 (2005)

JCPDS-Joint Commitee on Powder Diffraction Standards/International Center for Diffraction Data-ICDD, Powder Diffraction Data (Pennsylvania, JCPDS/ICDD, 1983)

L. Bian, F. Du, S. Yang, Q. Ren, Q.L., Liu. J. Lumin. 137, 168–172 (2013)

C.C. Viana, H.R. Paes Jr, Cerâmica 51 (317), 24–29 (2005).

M.S. Inpasalini, A. Singh, S. Mukherjee. J. Mater. Sci. Mater. Electron. 27, 4392–4398 (2016)

S. L. Ko, S. Park, C.-W. Kim, D. Lee, M.-S. Choi, C. Lee, C. Jin, Appl. Phys. A 121, 715–721 (2015)

R. Sánchez Zeferino, U. Pal, R. Meléndrez, M. Barboza Flores, Adv. Nano Res. 1(4), 193–202 (2013)

V. Geraldo, V. Briois, L.V.A. Scalvi, J. C.V. Santilli, Eur. Ceram. Soc 27, 4265–4268 (2007)

C.F. Bueno, D. H. O. Machado, T. F. Pineiz, L.V.A. Scalvi, Mater. Res. 16 (4), 831–838 (2013).

Acknowledgements

The authors would like to thank Prof. Andre L.J. Pereira for the help in preparing the GaAs films by sputtering, and the Brazilian agencies: CAPES, CNPq (Grant 471359/2013-0) and Grants 2006/00480-9 and 2016/12216-6 São Paulo Research Foundation (FAPESP).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Machado, D.H.O., Scalvi, L.V.A., Tabata, A. et al. Interface conduction and photo-induced electrical transport in the heterojunction formed by GaAs and Ce3+-doped SnO2 . J Mater Sci: Mater Electron 28, 5415–5424 (2017). https://doi.org/10.1007/s10854-016-6202-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6202-x