Abstract

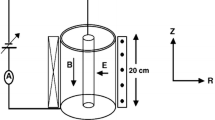

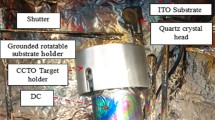

Polycrystalline CuO thin film was deposited by reactive RF magnetron sputtering technique. The samples obtained from CuO film were annealed in air for different times. The structural, compositional and optical properties of unannealed and annealed samples were characterized. The SEM studies showed that the samples have a homogeneous surface morphology. All of the samples exhibited strong \((\bar{1}11)\) diffraction peak and optical transmittance above 70%. As the annealing time was increased, the grain size increased and the optical band gap decreased.

Similar content being viewed by others

References

J. Sohn, S.-H. Song, D.-W. Nam, I.-T. Cho, E.-S. Cho, J.-H. Lee, H.-I. Kwon, Semicond. Sci. Technol. 28, 1 (2013)

E. Fortunato, P. Barquinha, R. Martins, Adv. Mater. 24, 2945 (2012)

K.C. Sanal, L.S. Vikas, M.K. Jayaraj, Appl. Surf. Sci. 297, 153 (2014)

M.F. Al-Kuhaili, Vacuum 82, 623 (2008)

A.H. Jayatissa, K. Guo, A.C. Jayasuriya, Appl. Surf. Sci. 255, 9474 (2009)

S. Visalakshi, R. Kannan, S. Valanarasu, H.-S. Kim, A. Kathalingam, R. Chandramohan, Appl. Phys. A 120, 1105 (2015)

C.R. Gobbiner, A.V.M. Ali, D. Kekuda, J. Mater. Sci. Mater. Electron. 26, 9801 (2015)

R. Shabu, A.M.E. Raj, C. Sanjeeviraja, C. Ravidhas, Mater. Res. Bull. 68, 1 (2015)

U. Akgul, K. Yildiz, Y. Atici, Eur. Phys. J. Plus 131(89), 1 (2016)

J.F. Chang, W.C. Lin, M.H. Hon, Appl. Surf. Sci. 183, 18 (2001)

F.A. Harraz, A.A. Ismail, S.A. Al-Sayari, A. Al-Hajry, J. Photochem. Photobiol. A 299, 18 (2015)

K. Huang, Q.N. Ling, C.H. Huang, K. Bi, W.J. Wang, T.Z. Yang, Y.K. Lu, J. Liu, R. Zhang, D.Y. Fan, Y.G. Wang, M. Lei, J. Alloys Compd. 646, 837 (2015)

Y. Zhang, J. Gu, M. Murugananthan, Y. Zhang, J. Alloys Compd. 630, 110 (2015)

J. Zhao, R. Liu, Z. Hua, Superlattice Microstruct. 81, 243 (2015)

L. Chabane, N. Zebbar, M.L. Zeggar, M.S. Aida, M. Kechouane, M. Trari, Mat. Sci. Semicond. Proc. 40, 840 (2015)

U.C. Bind, R.K. Dutta, G.K. Sekhon, K.L. Yadav, J.B.M. Krishna, R. Menon, P.Y. Nabhiraj, Superlattice Microstruct. 84, 24 (2015)

M. Thambidurai, N. Muthukumarasamy, A. Ranjitha, D. Velauthapillai, Superlattice Microstruct. 86, 559 (2015)

P.B. Nair, V.B. Justinvictor, G.P. Daniel, K. Joy, V. Ramakrishnan, D.D. Kumar, P.V. Thomas, Thin Solid Films 550, 121 (2014)

U. Akgul, Ph.D. Thesis, Firat University, Turkey (2015)

Acknowledgements

This study was supported by Scientific Research Projects Coordination Unit of Firat University (Project No. 1386).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akgul, U., Yildiz, K. & Atici, Y. Influence of annealing time on the physical properties of reactively sputtered CuO thin film. J Mater Sci: Mater Electron 28, 4758–4762 (2017). https://doi.org/10.1007/s10854-016-6120-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6120-y