Abstract

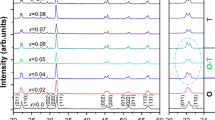

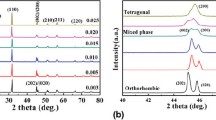

In this work, 0.954K1−x Na x NbO3–0.04Bi0.5Na0.5ZrO3–0.006BiFeO3 (KN x N–BNZ–BF) lead-free ceramics were fabricated by conventional ceramic technique. The effect of K/Na ratio on microstructure, phase structure and electrical properties was systematically investigated. The orthorhombic-tetragonal phase transition temperature (T O–T) increases and rhombohedral–orthorhombic phase transition temperature (T R–O) drops simultaneously with increasing the Na content, leading to an R–O–T phase boundaries in the ceramics with 0.44 ≤ x ≤ 0.60. By tailoring their K/Na ratio and optimizing the sintering temperature, an enhanced electrical properties (e.g. d 33 ~ 438 pC/N, k p ~ 0.51, T c ~ 320 °C, ε r ~ 2304 and tan δ ~ 0.029) was obtained at the ceramics with x = 0.56 sintered at 1090 °C, which could be attributed to the preferably density as well as the R–O–T phase boundary nearer the room temperature. Therefore, we think that the KN x N–BNZ–BF ceramic is a promising candidate for piezoelectric devices.

Similar content being viewed by others

References

S. Zhang, R. Xia, T.R. Shrout, J. Electroceram. 19, 251 (2007)

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics (Academic Press, New York, 1971)

EU-Directive 2002/96/EC, Waste electrical and electronic equipment (WEEE). Off. J. Eur. Union 46(L37), 24 (2003)

EU-Directive 2002/95/EC, Restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS). Off. J. Eur. Union 46(L37), 19 (2003)

B. Wu, C. Han, D.Q. Xiao, Z. Wang, J.G. Zhu, J.G. Wu, Mater. Res. Bull. 47(11), 3937 (2012)

B. Wu, D.Q. Xiao, W.J. Wu, J.G. Zhu, Q. Cheng, J.G. Wu, Ceram. Int. 38(7), 5677 (2012)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84 (2004)

B. Wu, D.Q. Xiao, J.G. Wu, Q. Gou, J.G. Zhu, J. Mater. Sci.: Mater. Electron. 26(4), 2323 (2015)

R.Z. Zuo, C. Ye, X.S. Fang, J. Phys. Chem. Solids 69, 230 (2008)

B. Wu, D.Q. Xiao, J.G. Wu, Q. Gou, D.D. Mazhao, J.G. Zhu, Ferroelectrics 489(1), 129 (2015)

B. Wu, J.G. Wu, D.Q. Xiao, J.G. Zhu, Dalton Trans. 44(48), 21141 (2015)

J. Wu, D. Xiao, J. Zhu, Chem. Rev. 115(7), 2559 (2015)

T. Takenaka, H. Nagata, J. Eur. Ceram. Soc. 25(12), 2693 (2005)

F.Z. Yao, K. Wang, W. Jo, J.F. Li, Adv. Funct. Mater. 26, 1217 (2016)

W.F. Liang, W.J. Wu, D.Q. Xiao, J.G. Zhu, J. Am. Ceram. Soc. 94(12), 4317 (2011)

N. Liu, K. Wang, J.F. Li, Z. Liu, J. Am. Ceram. Soc. 92(8), 1884 (2009)

J.G. Wu, D.Q. Xiao, Y.Y. Wang, J.G. Zhu, L. Wu, Y.H. Jiang, Appl. Phys. Lett. 91(25), 252907 (2007)

D. Damjanovic, N. Klein, J. Li, V. Porokhonskyy, Funct. Mater. Lett. 3, 5 (2010)

X.P. Wang, J.G. Wu, D.Q. Xiao, J.G. Zhu, X.J. Cheng, T. Zheng, B.Y. Zhang, X.J. Lou, X.J. Wang, J. Am. Chem. Soc. 136, 2905 (2014)

K. Xu, J. Li, X. Lv, J.G. Wu, X.X. Zhang, D.Q. Xiao, J.G. Zhu, Adv. Mater. 28, 8519 (2016)

L. Fu, D. Lin, Q. Zheng, X. Wu, C. Xu, Phys. Status Solidi (a) 209(11), 2299 (2012)

D. Lin, K.W. Kwok, H.L.W. Chan, J. Appl. Phys. 91, 167 (2008)

J.G. Wu, D.Q. Xiao, Y.Y. Wang, J.G. Zhu, P. Yu, J. Appl. Phys. 103, 024102 (2008)

L. Wu, J.L. Zhang, C.L. Wang, J.C. Li, J. Appl. Phys. 103, 084116 (2008)

Y.J. Dai, X.W. Zhang, K.P. Chen, Appl. Phys. Lett. 94, 042905 (2009)

J.G. Wu, D.Q. Xiao, Y.Y. Wang, J.G. Zhu, L. Wu, Appl. Phys. Lett. 91, 252907 (2007)

L. Wu, J.L. Zhang, S.F. Shao, P. Zheng, C.L. Wang, Appl. Phys. Lett. 41, 035402 (2008)

V.J. Tennery, K.W. Hang, J. Appl. Phys. 39, 4749 (1968)

M. Ahtee, A.M. Glazer, Acta Crystallogr. 32, 434 (1976)

B.Y. Zhang, J.G. Wu, B. Wu, J.G. Wu, D.Q. Xiao, J.G. Zhu, J. Alloys Compd. 525, 53 (2012)

J.G. Wu, X.P. Wang, X.T. Zheng, B.Y. Zhang, D.Q. Xiao, J.G. Zhu, X.J. Lou, J. Appl. Phys. 115(11), 114104 (2014)

S.S. Feng, D.Q. Xiao, J.G. Wu, F.X. Li, M. Xiao, J.G. Zhu, J. Electroceram. 34(2–3), 142 (2015)

B.P. Zhang, J.F. Li, K. Wang, J. Am. Ceram. Soc. 89, 1605 (2006)

E. Rigaard, T. Wurlitzer, J. Eur. Ceram. Soc. 25, 2701 (2005)

J.F. Tressler, S. Alkoy, R.E. Newnham, J. Electroceram. 2(4), 257 (1998)

Acknowledgements

This work was supported by Project (Grant Nos. KYTZ201312 and J201220) Supported by the Scientific Research Foundation of CUIT, the Fundamental Research Funds for the Central Universities of Southwest University for Nationalities (No. 2014NZYQN11), the Foundation of Sichuan province science and technology support program, China (Grant No. GZ0198) and Scientific Research Project of Sichuan Provincial Department of Education (Grant No. 16ZA0216).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, J., Wu, B., Wu, W. et al. Microstructure, phase structure and electrical properties of 0.954K1−x Na x NbO3–0.04Bi0.5Na0.5ZrO3–0.006BiFeO3 lead-free ceramics. J Mater Sci: Mater Electron 28, 4458–4466 (2017). https://doi.org/10.1007/s10854-016-6075-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6075-z