Abstract

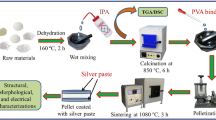

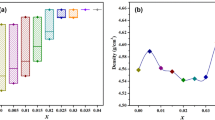

In this work, the 0.96(K0.5Na0.5)(Nb0.96Sb0.04)O3–0.04Bi0.5(Na0.5K0.5)0.5ZrO3 (KNNS–BNKZ) ceramics were prepared by the conventional solid-state method, and effects of calcination temperatures (T cal) on their microstructure, phase structure, and electrical properties were investigated in detail. It was found that the calcination temperatures strongly affect the phase structure of the ceramics, that is, rhombohedral–orthorhombic–tetragonal phase coexistence for T cal = 500–600 °C and rhombohedral–tetragonal phase coexistence for T cal = 650–950 °C. In addition, their electrical properties are also very sensitive to the calcination temperatures. A high piezoelectricity of 450–475 pC/N can be attained in a wide calcination temperature of 750–900 °C, and especially the ceramics calcined at 850 °C exhibit optimum electrical properties: d 33 = 475 pC/N, k p = 0.51, ε r = 2561, tan δ = 0.033, P r = 15.2 μC/cm2, E C = 7.1 kV/cm, and T C = 222 °C. In addition, all the ceramics exhibit a good thermal stability of piezoelectric activity. As a result, we believe that the electrical properties of KNN-based ceramics can be well controlled by optimizing calcination condition.

Similar content being viewed by others

References

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics (Academic, London, 1971), p. 271

J.G. Wu, D.Q. Xiao, W.J. Wu, Q. Chen, J.G. Zhu, Z.C. Yang, J. Wang, J. Eur. Ceram. Soc. 32, 891 (2012)

H. Nagata, M. Yoshida, Y. Makiuchi, T. Takenaka, Jpn. J. Appl. Phys. 42, 7401 (2003)

J.G. Wu, D.Q. Xiao, W.J. Wu, Q. Chen, J.G. Zhu, Z.C. Yang, J. Wang, Scr. Mater. 65, 771 (2011)

L.F. Zhu, B.P. Zhang, L. Zhao, J.F. Li, J. Mater. Chem. C 2, 4764 (2014)

P. Fu, Z. Xu, R. Chu, X. Wu, W. Li, X. Li, Mater. Design 46, 322 (2013)

X. Chao, J. Wang, P. Liang, T. Zhang, L. Wei, Z. Yang, Mater. Design 89, 465 (2016)

J.G. Wu, D.Q. Xiao, J.G. Zhu, Chem. Rev. 115, 2559 (2015)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84 (2004)

K. Xu, J. Li, X. Lv, J.G. Wu, X.X. Zhang, D.Q. Xiao, J.G. Zhu, Adv. Mater. (2016). doi:10.1002/adma.201601859

K. Wang, J.F. Li, J.J. Zhou, Appl. Phys. Express. 4, 061501 (2011)

X.P. Wang, J.G. Wu, D.Q. Xiao, J.G. Zhu, X.J. Cheng, T. Zheng, B.Y. Zhang, X.J. Lou, X.J. Wang, J. Am. Chem. Soc. 136, 2905 (2014)

R.Z. Zuo, J. Fu, J. Am. Ceram. Soc. 94, 1467 (2010)

H. Tian, C.P. Hu, X.D. Meng, Z.X. Zhou, G. Shi, J. Mater. Chem. C 3, 9609 (2015)

B. Malic, J. Bernard, A. Bencan, M. Kosec, J. Eur. Ceram. Soc. 28, 1191 (2008)

T.R. Shrout, S.J. Zhang, J. Electroceram. 19, 111 (2007)

W.J. Wu, M. Chen, J. Li, Y. Ding, C. Liu, J. Alloys Compd. 670, 128 (2016)

W.J. Wu, D.Q. Xiao, J.G. Wu, W.F. Liang, J. Li, J.G. Zhu, J. Alloys Compd. 509, L284 (2011)

F.Z. Yao, K. Wang, W. Jo, J.S. Lee, J.F. Li, J. Appl. Phys. 116, 114102 (2014)

L. Li, Y. Gong, L.J. Gong, H. Dong, X.F. Yi, X.J. Zheng, Mater. Design 33, 362 (2012)

E.K. Akdoğan, K. Kerman, M. Abazari, A. Safari, Appl. Phys. Lett. 92, 112908 (2008)

W. Wu, J. Li, D. Xiao, M. Chen, Y. Ding, C. Liu, Ceram. Int. 40, 13205 (2014)

E. Hollenstein, M. Davis, D. Damjanovic, N. Setter, Appl. Phys. Lett. 87, 182905 (2005)

Y. Guo, K. Kakimoto, H. Ohsato, Appl. Phys. Lett. 85, 4121 (2004)

W. Wu, D. Xiao, J. Wu, J. Li, J. Zhu, B. Zhang, Ceram. Int. 38, 2277 (2012)

J. Wu, X. Wang, X. Cheng, T. Zheng, B. Zhang, D. Xiao, J. Zhu, X. Lou, J. Appl. Phys. 115, 114104 (2014)

J.J. Zhou, L.Q. Cheng, K. Wang, X.W. Zhang, J.F. Li, H. Liu, J.Z. Fang, Ceram. Int. 40, 2927 (2014)

P. Palei, M. Pattanaik, P. Kumar, Ceram. Int. 38, 851 (2012)

B. Liu, Y. Zhang, P. Li, B. Shen, J. Zhai, Ceram. Int. 42, 13824 (2016)

D. Zhang, Z. Cheng, J. Cheng, F. Shi, X. Yang, G. Zheng, M. Cao, Ceram. Int. 42, 9073 (2016)

Acknowledgments

This work was supported by Project (Grant No. J201612) Supported by the Scientific Research Foundation of CUIT, the Foundation of Sichuan province science and technology support program, China (Grant No. GZ0198) and Scientific Research Project of Sichuan Provincial Department of Education (Grant No. 16ZA0216).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, W., Chen, M., Bo, W. et al. Modulation of electrical properties of KNNS–BNKZ lead-free ceramics by calcination temperatures. J Mater Sci: Mater Electron 28, 2086–2092 (2017). https://doi.org/10.1007/s10854-016-5770-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5770-0