Abstract

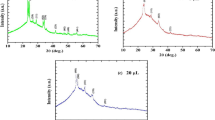

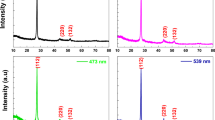

It is of great importance to do research on the preparation and applications of the Mg2Si film as an ecological friendly semiconducting material. Semiconducting Mg2Si films were prepared by electron beam evaporation deposition of Mg film onto Si substrate and subsequent heat treatment. X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to characterize and analyse the obtained Mg2Si films. Effects of heat treatment temperature (300–700 °C) under Ar gas pressure (200 Pa) on the crystal structure and surface morphologies of Mg2Si films were investigated. The XRD results show that heat treatment at 400–500 °C for 4–5 h is the optimal heat treatment condition to prepare Mg2Si films by the diffusion between the Mg atoms and Si atoms, and high temperature treatment above 600 °C causes the decomposition of Mg2Si and the formation of MgO. The SEM images show that the surfaces of obtained films become smooth and compact with the increase in heat treatment temperature. However, significant differences on the surface of the films occur when heat temperature is above 600 °C because of the decomposition of Mg2Si phase and the formation of MgO phase. These experimental results are beneficial to the development of optoelectronic devices based on the Mg2Si films.

Similar content being viewed by others

References

V. Borisenko, Semiconducting Silicides (Springer, New York, 2000)

H. Udono, H. Tajima, M. Uchikoshi, M. Itakura, Jpn. J. Appl. Phys. 54, 07JB06 (2015)

H. Udono, Y. Yamanaka, M. Uchikoshi, M. Isshiki, J. Phys. Chem. Solids 74, 311 (2013)

T. Kato, Y. Sago, H. Fujiwara, J. Appl. Phys. 110, 063723 (2011)

G. Tompa, Y. Li, D. Agassi, S. Kim, S. Hong, J. Electron. Mater. 25, 925 (1996)

A. Vantomme, J. Mahan, G. Langouche, Appl. Phys. Lett. 70, 1086 (1997)

J.L. Margrave, The characterization of high-temperature vapors (Wiley, New York, 1967)

J. Mahan, A. Vantomme, G. Langouche, J. Becker, Phys. Rev. B 54, 16965 (1996)

X. Wang, Y. Wang, J. Zou, Chin. Phys. B 18, 3079 (2009)

S.W. Song, K.A. Striebel, R.P. Reade, G.A. Roberts, E.J. Cairns, J. Electrochem. Soc. 150, A121 (2003)

T. Serikawa, M. Henmi, T. Yamaguchi, H. Oginuma, K. Kondoh, Surf. Coat. Tech. 200, 4233 (2006)

N.G. Galkin, S.V. Vavanova, A.M. Maslov, K.N. Galkin, A.V. Gerasimenko, T.A. Kaidalova, Thin Solid Films 515, 8230 (2007)

R. Nakagawa, H. Katsumata, S. Hashimoto, A. Sakuragi, Jpn. J. Appl. Phys. 54, 085503 (2015)

Q. Xiao, Q. Xie, X. Shen, J. Zhang, Z. Yu, K. Zhao, Appl. Surf. Sci. 257, 7800 (2011)

H. Yu, Q. Xie, Q. Chen, J. Mater. Sci. Mater. El. 24, 3768 (2013)

A. Vantomme, G. Langouche, J. Mahan, J. Becker Microelectron. Eng. 50, 237 (2000)

H.Y. Jiang, Y.G. Leng, L.M. Zhang, J. Wuhan Univ. Technol. 23, 7 (2001)

J.-I. Tani, M. Takahashi, H. Kido, J. Alloys Compd. 488, 346 (2009)

Acknowledgments

The work was partly supported by the National Natural Science Foundation of China (61264004), the Fund for International Sci-Tech Cooperation Program of Guizhou Province, China ([2013]7003), the Natural Science Foundation of Guizhou Province, China ([2014]2052, [2013]2209), the Open Fund from Engineering Center for Avionics Electrical and Information Network of Guizhou Provincial Colleges and Universities, China (HKDZ201403) and Sci-Tech Program of Guiyang City of Guizhou Province, China ([2012101]2-16).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, Q., Fang, D., Liu, X. et al. Heat treatment temperature effects on the formation of Mg2Si films deposited by electron beam evaporation. J Mater Sci: Mater Electron 28, 702–706 (2017). https://doi.org/10.1007/s10854-016-5579-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5579-x