Abstract

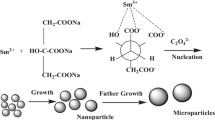

1064 nm laser stealth absorbent Sm2O2S was prepared by solid state flux method. The effects of doping Er3+ and Tm3+ on the powder’s phase compositions and reflecting property were investigated. The phase composition, morphology and reflectivity of powders were characterized by X-ray diffraction, scanning electron microscopy and ultraviolet visible spectrophotometer (UV-3600PC). The results exhibited that doping Er3+ and Tm3+ cause no significant changes on crystal structure. However, the morphology of powders changed a lot after doping Er3+/Tm3+, which influenced on the reflecting property. Because of the characteristic absorption of Er3+ and Tm3+, the reflectivity of Sm2O2S powders decreased in different degrees. The doping amount of Er3+ was 15 mol%, the lowest reflectivity 0.7450 % was obtained. The optimized doping amount of Tm3+ was 10 mol% and the reflectivity was 0.7403 %.

Similar content being viewed by others

References

Y. Hwang, C.S. Park, J. Kim, J. Kim, J.Y. Lim, H. Choi, J. Jo, E. Lee, Renew. Energy 79, 131 (2015)

S.J. Mathews, S.C. Kumar, L. Giribabu, S.V. Rao, Mater. Lett. 61(22), 4426 (2007)

X.G. Huang, Y.Y. Chen, J.H. Yu, J. Zhang, T.Y. Sang, G.X. Tao, H.L. Zhu, J. Mater. Sci.: Mater. Electron. 26(6), 3474 (2015)

X.G. Huang, J. Zhang, W.F. Rao, T.Y. Sang, B. Song, C.P. Wong, J. Alloys Compd. 662, 409 (2016)

X.G. Huang, J. Zhang, Z.H. Liu, T.Y. Sang, B. Song, H.L. Zhu, C.P. Wong, J. Alloys Compd. 648, 1072 (2015)

X.G. Huang, J. Zhang, M. Lai, T. Sang, J. Alloys Compd. 627, 367 (2015)

W. He, J. Zhang, L.X. Wang, Q.T. Zhang, J. Rare Earths 27(2), 231 (2009)

Y.Q. Zhu, P.D. Han, L. Zhang, L.X. Wang, Q.T. Zhang, J. Rare Earths 31(11), 1102 (2013)

P.D. Han, X.P. Jiang, L.T. Zhang, F.L. Yu, Q.L. Shi, Y.J. Ding, Q.T. Zhang, J. Mater. Sci.: Mater. Electron. 26(2), 266 (2015)

P.D. Han, X.P. Jiang, Adv. Powder Technol. 26(3), 977 (2015)

X.X. Luo, W.H. Cao, J. Alloys Compd. 460(1–2), 529 (2008)

P.V.M. Dixini, V.G. Celante, M.F.F. Lelis, M.B.J.G. Freitas, J. Power Sources 260(16), 163 (2014)

S. Tan, S.N. Paglieri, D. Li, Catal. Commun. 73, 16 (2016)

X. Lu, L. Yang, Q. Ma, J. Tian, X.T. Dong, J. Mater. Sci.: Mater. Electron. 25(12), 5388 (2014)

I. Hyppänena, J. Hölsäa, J. Kankarea, M. Lastusaaria, L. Pihlgrena, Opt. Mater. 31(12), 1787 (2009)

P.D. Han, X.G. Huang, Q.T. Zhang, Rare Met. 30(6), 616 (2011)

K. Zhu, W.H. Ding, W. Sun, P.D. Han, L.X. Wang, Q.T. Zhang, J. Mater. Sci.: Mater. Electron. 27(3), 2379 (2016)

F. Wang, B. Yang, X. Chen, W. Ma, B. Xu, J. Mater. Chem. Phys. 169, 113 (2015)

J. Bang, M. Abboudi, B. Abrams, P.H. Holloway, J. Lumin. 106(3–4), 177 (2004)

P.D. Han, X.P. Jiang, M.Y. Xu, F.L. Yu, B.X. Jiao, R.F. Guan, Q.T. Zhang, Mater. Res. Bull. 70, 658 (2015)

Acknowledgments

This work was supported by National Natural Science Foundation of China (51202111), College Industrialization Project of Jiangsu Province (JHB2012-12) and the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, W., Zhu, K., Xu, H. et al. Enhanced absorbing property of Sm2O2S laser absorbent by doping Er3+/Tm3+ . J Mater Sci: Mater Electron 28, 697–701 (2017). https://doi.org/10.1007/s10854-016-5578-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5578-y