Abstract

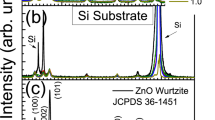

In this study, zinc sulfide (ZnS) nanostructures with different morphologies were effectively fabricated on glass substrates at 200 °C via spray pyrolysis. The Zn2+ and S2− ions were sourced from aqueous solutions of zinc acetate and thiourea, respectively. The samples were deposited at different spray distances (15, 20, 25, 30 and 35 cm) in order to examine the effect of spray distance on the optical and structure properties of synthesized ZnS nanostructures. Following the deposition procedure, the films were characterized using X-ray diffraction, UV–Vis–NIR spectrometry, photoluminescence (PL) spectroscopy and field emission scanning electron microscopy. The crystallinity and morphology of the cubic ZnS films were found to vary with spray distance, where the average particle size appears to increase with the increasing spray distance. The highest absorption values were obtained for ZnS films crystallized at a spray distance of 30 cm. The PL analysis specified the presence of violet and green emissions, which are attributable to Zn and S vacancies. The band gap of the ZnS films was observed to decrease slightly from 3.82 to 3.30 eV with the increasing spray distance. The results indicate that the spraying distance affects the characteristics of ZnS nanostructures.

Similar content being viewed by others

References

L. Li, R. Xie, Y. Gu, J. Huang, J. Zhu, Appl. Surf. Sci. 258, 5992 (2012)

N.K. Abbas, K.T. Al-Rasoul, Z.J. Shanan, Int. J. Electrochem. Sci. 8, 3049 (2013)

M. Pal, N. Mathews, E.R. Morales, J.G.y. Jiménez, X. Mathew, Opt. Mater. 35, 2664 (2013)

V. Ramasamy, K. Praba, G. Murugadoss, Superlattices Microstruct. 51, 699 (2012)

K. Ashwini, C. Pandurangappa, B. Nagabhushana, Phys. Scr. 85, 065706 (2012)

F. Rahman, M. Zahan, J. Podder, Sens. Transducers 149, 54 (2013)

D. Ayodhya, M. Venkatesham, A.S. Kumari, K.G. Mangatayaru, G. Veerabhadram, IOSR J. Appl. Chem. 6, 1 (2013)

T. Zhai, L. Li, Y. Ma, M. Liao, X. Wang, X. Fang, J. Yao, Y. Bando, D. Golberg, Chem. Soc. Rev. 40, 2986 (2011)

P.-C. Tsai, I. Pai, and H. Shieh, in Photovoltaic Specialists Conference (PVSC), 2012 38th IEEE, p. 001992

Z.Y. Zhong, E.S. Cho, S.J. Kwon, Mater. Chem. Phys. 135, 287 (2012)

C. Pathak, D. Mishra, V. Agarwala, M. Mandal, Ceram. Int. 38, 5497 (2012)

R. Viswanath, H.B. Naik, G.Y. Kumar, P.P. Kumar, G.A. Kumar, R. Praveen, J. Lumin. 153, 446 (2014)

H. Hennayaka, H.S. Lee, Thin Solid Films 548, 86 (2013)

A.A. Yousif, A.A. Jasib, Int. J. Innov. Sci. Eng. Technol. 2, 3 (2015)

K.B. Bacha, A. Timoumi, N. Bitri, H. Bouzouita, Optik-Int. J. Light Electron Opt. 126, 3020 (2015)

X. Zeng, S.S. Pramana, S.K. Batabyal, S.G. Mhaisalkar, X. Chen, K. Jinesh, PCCP 15, 6763 (2013)

S.S. Kumar, M.A. Khadar, S. Dhara, T. Ravindran, K. Nair, Nucl. Instrum. Methods Phys. Res. B 251, 435 (2006)

Acknowledgments

The authors gratefully acknowledge the financial support by the University Sains Malaysia fellowship and School of Physics, under Grant Nos. 1001/PFIZIK/811175 and 304/PFIZIK/6312076.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Diabat, A.M., Ahmed, N.M., Hashim, M.R. et al. Influence of the spray distance to substrate on optical properties of chemically sprayed ZnS thin films. J Mater Sci: Mater Electron 28, 371–375 (2017). https://doi.org/10.1007/s10854-016-5532-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5532-z