Abstract

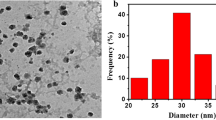

A kind of copper mixed ink with low sintering temperatures was developed. The mixed ink was composed of copper nanoparticles and copper formate 3-dimethylamino-1,2-propanediol (DMAPD) complex. TG-MS showed a two-step decomposition process of the mixed ink below 200 °C. The copper formate DMAPD complex decomposed to copper nanoparticles at about 140 °C. The freshly formed small copper nanoparticles dispersed around the large copper nanoparticles of the ink, and then sintered at relatively low temperatures to form connections between larger nanoparticles. The copper films were obtained by thermally sintering of the mixed ink films at different temperatures. The mixed ink with 38 wt% of copper formate complex gave a film with the lowest resistivity of 18 μΩ cm after sintering at 200 °C, which is less than one thirtieth of that of the film without copper formate complex at the same sintering temperature. The morphology analysis showed the dense copper films from the mixed ink, in contrast to the loose film from the organic decomposition ink made of copper formate complex.

Similar content being viewed by others

References

A. Kamyshny, S. Magdassi, Small 10, 3515 (2014)

S.B. Walker, J.A. Lewis, J. Am. Chem. Soc. 134, 1419 (2012)

P. Calvert, Chem. Mater. 13, 3299 (2001)

Y. Kim, B. Lee, S. Yang, I. Byun, I. Jeong, S.M. Cho, Curr. Appl. Phys. 12, 473 (2012)

A. Kamyshny, J. Steinke, S. Magdassi, Open Appl. Phys. J. 4, 19 (2011)

W. Li, W. Li, J. Wei, J. Tan, M. Chen, Mater. Chem. Phys. 146, 82 (2014)

Y. Zhang, P. Zhu, G. Li, T. Zhao, X. Fu, R. Sun, F. Zhou, C. Wong, ACS Appl. Mater. Interfaces 6, 560 (2014)

N.R. Kim, K. Shin, I. Jung, M. Shin, H.M. Lee, J. Phys. Chem. C 118, 26324 (2014)

C. Dong, H. Cai, X. Zhang, C. Cao, Phys. E 57, 12 (2014)

S. Magdassi, M. Grouchko, A. Kamyshny, Materials 3, 4626 (2010)

C.K. Kim, G.J. Lee, M.K. Lee, C.K. Rhee, Powder Technol. 263, 1 (2014)

D. Deng, Y. Cheng, Y. Jin, T. Qi, F. Xiao, J. Mater. Chem. 22, 23989 (2012)

W. Chen, D. Deng, Y. Cheng, F. Xiao, J. Electron. Mater. 44, 2479 (2015)

Y. Farraj, M. Grouchko, S. Magdassi, Chem. Commun. 51, 1587 (2015)

B. Lee, Y. Kim, S. Yang, I. Jeong, J. Moon, Curr. Appl. Phys. 9, 157 (2009)

D. Shin, S. Woo, H. Yem, M. Cha, S. Cho, M. Kang, S. Jeong, Y. Kim, K. Kang, Y. Piao, ACS Appl. Mater. Interfaces 6, 3312 (2014)

S.J. Kim, J. Lee, Y.H. Choi, D.H. Yeon, Y. Byun, Thin Solid Films 520, 2731 (2012)

D.Y. Shin, M. Jung, S. Chun, J. Mater. Chem. 22, 11755 (2012)

A. Yabuki, N. Arriffin, M. Yanase, Thin Solid Films 519, 6530 (2011)

A. Yabuki, S. Tanaka, Mater. Res. Bull. 47, 4107 (2012)

D. Deng, T. Qi, Y. Cheng, Y. Jin, F. Xiao, J. Mater. Sci. Mater. Electron. 25, 390 (2014)

A. Yabuki, Y. Tachibana, I.W. Fathona, Mater. Chem. Phys. 148, 299 (2014)

A. Keller, F. Korosy, Nature 162, 580 (1948)

Y. Ji, Y. Liu, G. Huang, X. Shen, H. Xiao, S. Fu, ACS Appl. Mater. Interfaces 7, 8041 (2015)

W. Yang, C. Liu, Z. Zhang, Y. Liu, S. Lie, J. Mater. Sci. Mater. Electron. 24, 5175 (2013)

Acknowledgments

This research was supported by the National Science and Technology Major Project of China (No. 2013ZX02505).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, Y., Qi, T., Chen, M. et al. Mixed ink of copper nanoparticles and copper formate complex with low sintering temperatures. J Mater Sci: Mater Electron 27, 11432–11438 (2016). https://doi.org/10.1007/s10854-016-5269-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5269-8